Novel AOD spiral side gun

A spiral type, side gun technology, applied in the field of the new AOD spiral side gun, can solve the problems of short life of the furnace lining, uneven wear and erosion, etc., and achieve the effect of active molten pool, restraining mechanical erosion, and strong fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

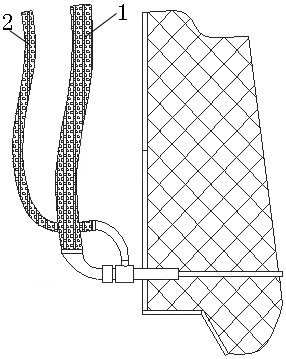

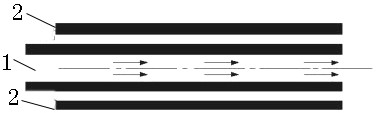

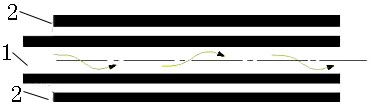

[0018] Such as Figure 1-5 Shown: a new AOD spiral side gun, which includes a main gun 1, a sub-gun 2 and a spiral liner 3, the main gun is used as a central tube, the sub-gun is set on the outside of the main gun, the main gun and the sub-gun Coaxial setting; the main gun is provided with a spiral liner to make the gas in the main gun rotate.

[0019] The spiral liner is copper with a thickness of 2mm and a pitch of 700mm. If the pitch is too small, the gas flow in the main gun will be affected, and the flow and pressure at the outlet will be significantly reduced, which will affect the refining effect and time; if the pitch is too large, the air flow passing through the main gun will not be able to rotate, and the refining effect will not be improved.

[0020] Described main gun is copper, and its thickness is 3mm, and the diameter of outer wall is 21mm.

[0021] The secondary gun is made of stainless steel with a thickness of 4mm and a diameter of the outer wall of 34mm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com