Wastewater preprocessing catalytic reduction reactor and wastewater preprocessing system and technology thereof

A reactor and pretreatment technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of reduced degree of hardening, easy hardening of the reactor, and large amount of sludge produced. and other problems, to achieve the effect of improving biodegradability, avoiding production stoppage, and reducing chroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

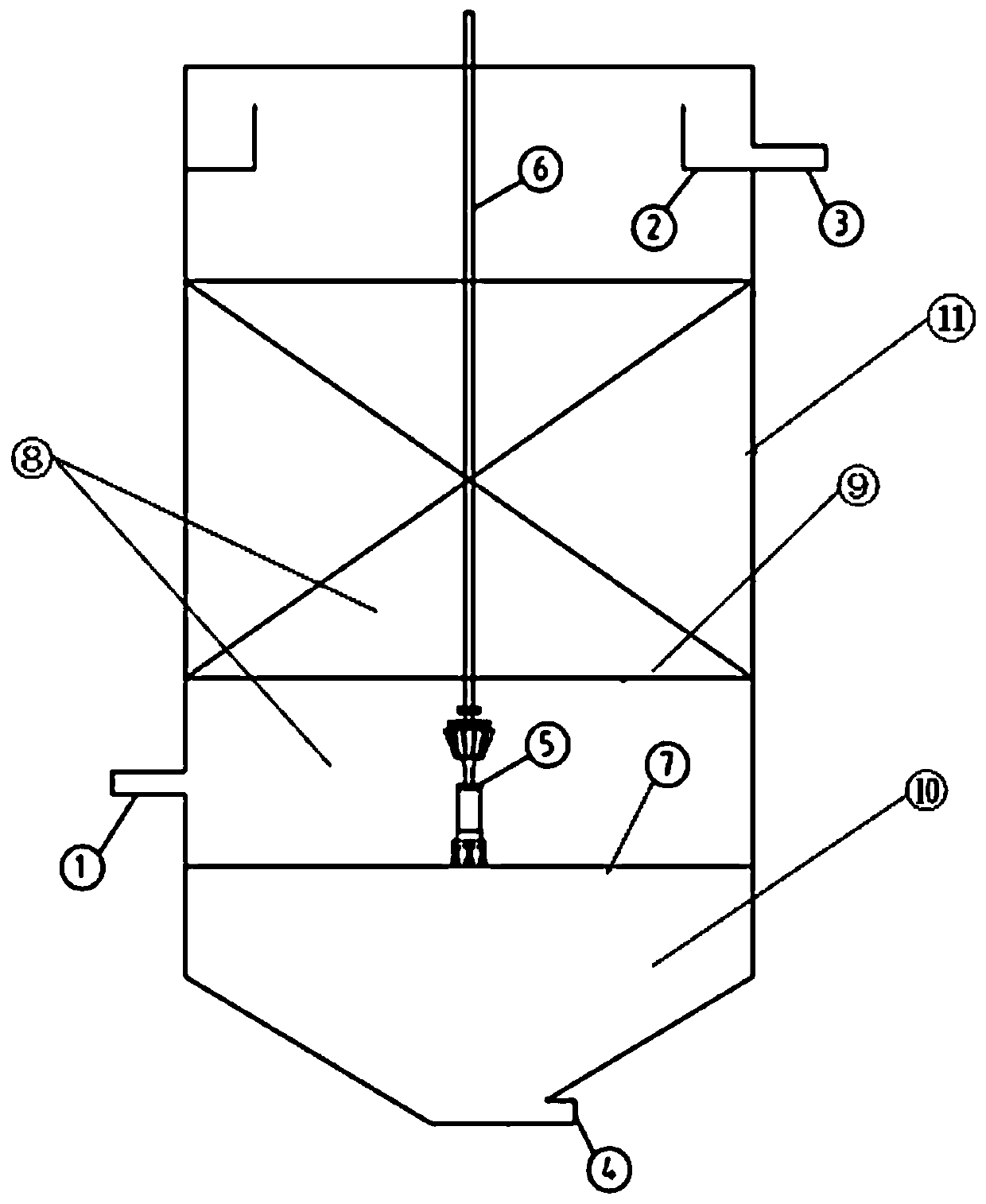

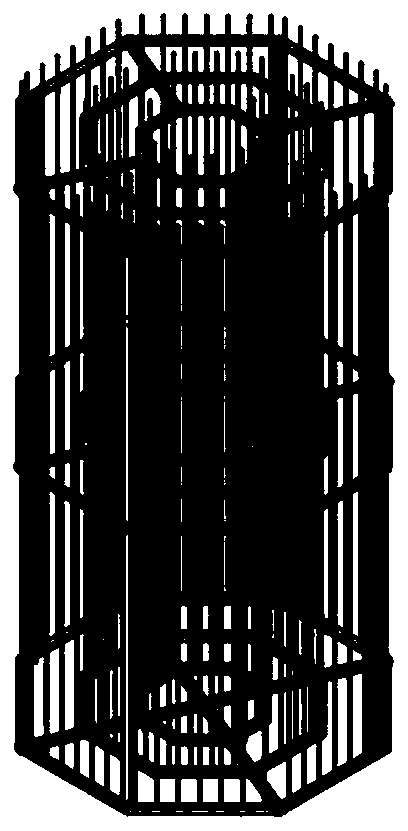

[0027] see figure 1 , in one embodiment, a kind of waste water pretreatment catalytic reduction reactor, can handle the industrial waste water (such as printing and dyeing waste water, dye waste water, electroplating waste water, etc.) , rotary cutting mixed flow aerator 5, rolled iron-aluminum mixture, catalyst frame (such as figure 2 Shown), the reactor body 11 includes a reaction zone 8 and a sludge settling zone 10; the sludge settling zone 10 is at the bottom of the reactor body 11, and the reaction zone 8 is at the top of the sludge settling zone 10;

[0028] The lower part of the reaction zone 8 is provided with a raw water inlet 1, and the upper part of the reaction zone 8 is provided with a water outlet 3. The catalyst frame is set in the reaction zone 8, and the rolled iron-aluminum mixture is placed in the catalyst frame. 5 is arranged at the bottom of the reaction zone 8, and the inlet pipe 6 of the rotary cutting mixed-flow aerator 5 passes through the catalyst ...

Embodiment 2

[0036] A wastewater pretreatment system can be used to treat industrial wastewater containing refractory and toxic organic matter (such as printing and dyeing wastewater, dye wastewater, electroplating wastewater, etc.) Reduction reactor, sedimentation tank, gas supply device, wastewater stirring tank;

[0037] Among them, the wastewater stirring tank is connected to the raw water inlet 1 of the reactor, the gas supply device is connected to the inlet pipe 6 of the rotary shear mixed flow aerator 5 in the reactor, and the water outlet 3 of the reactor is connected to the sedimentation tank.

[0038] Use the treatment process of the waste water treatment system in embodiment 2, comprise catalytic reduction and coagulation sedimentation;

[0039] Catalytic reduction further includes: the waste water to be treated enters the reactor from the raw water inlet 1 after adding acid in the waste water stirring tank to adjust the pH, and a reduction reaction occurs in the reactor. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com