Polypropylene halogen-free flame-retardant material and preparation method thereof

A flame retardant material, polypropylene technology, applied in the field of polypropylene, can solve the problems of poor toughness and easy whitening of polypropylene, and achieve the effects of improving elongation at break, reducing dosage requirements, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

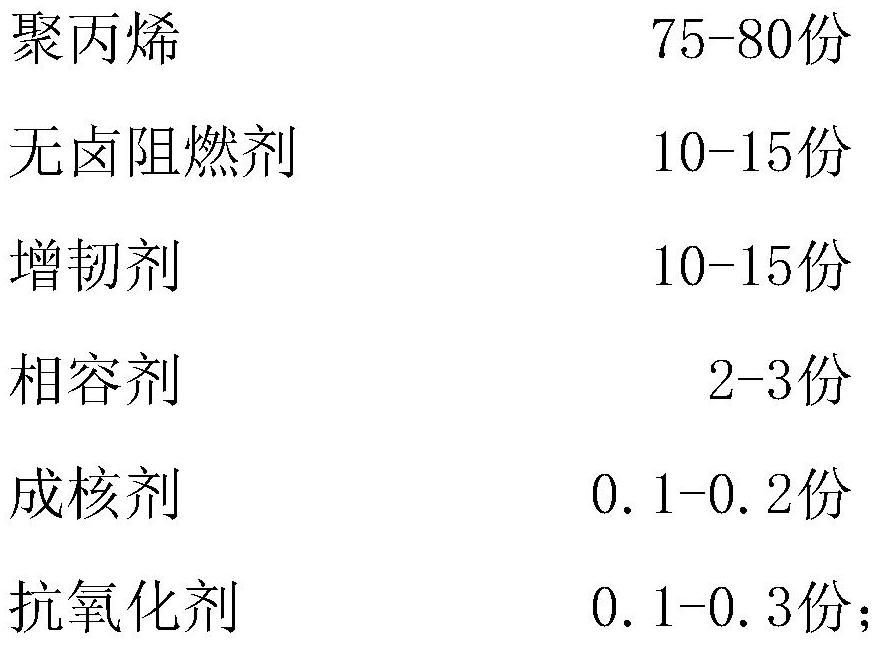

[0025] A polypropylene halogen-free flame-retardant material, comprising the following raw materials in parts by weight:

[0026]

[0027] Described toughening agent is made through the following steps:

[0028] (1) Add 50 parts by weight of nano-silica and 1 part by weight of γ-aminopropyltriethoxysilane to 100 parts by weight of absolute ethanol, ultrasonically disperse for 2 hours, then centrifuge, wash and dry to obtain Modified nano silica;

[0029] (2) Add 40 parts by weight of diphenylmethane diisocyanate and 20 parts by weight of modified nano-silicon dioxide in 100 parts by weight of dimethylacetamide, heat up to 50°C and stir for 2h, then drop to normal temperature, Add 25 parts by weight of polytetrahydrofuran ether glycol and 0.1 part by weight of catalyst, raise the temperature to 50°C and react for 2 hours, add 100 parts by weight of deionized water, and after the precipitation is completely precipitated, add 20 parts by weight of nano aluminum hydroxide, and...

Embodiment 2

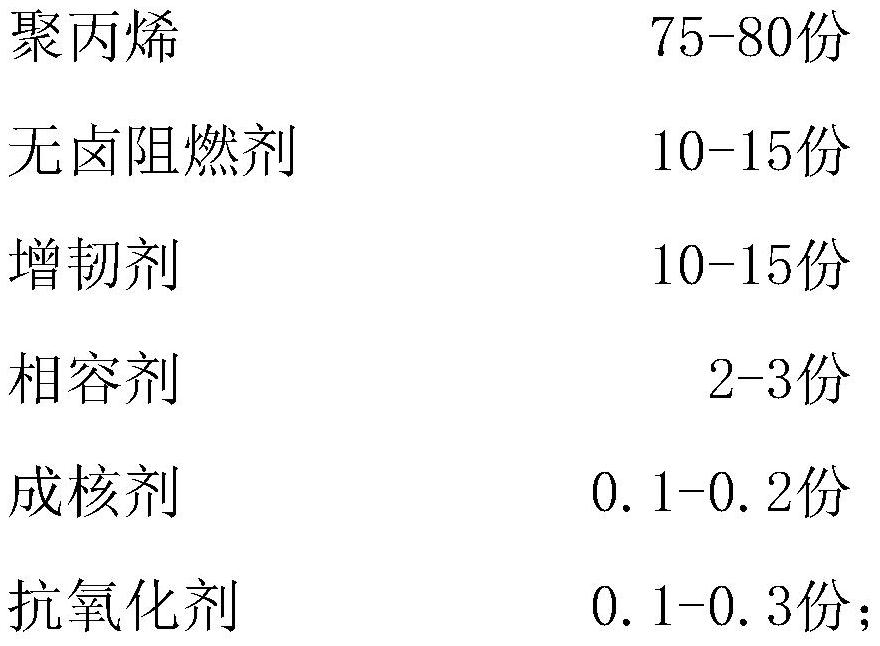

[0040] A polypropylene halogen-free flame-retardant material, comprising the following raw materials in parts by weight:

[0041]

[0042] Described toughening agent is made through the following steps:

[0043] (1) Add 60 parts by weight of nano silicon dioxide and 3 parts by weight of γ-aminopropyltriethoxysilane to 100 parts by weight of absolute ethanol, ultrasonically disperse for 3 hours, then centrifuge, wash and dry to obtain Modified nano silica;

[0044] (2) Add 50 parts by weight of diphenylmethane diisocyanate and 30 parts by weight of modified nano-silicon dioxide in 100 parts by weight of dimethylacetamide, heat up to 70°C and stir for 3h, then drop to normal temperature, Add 30 parts by weight of polytetrahydrofuran ether glycol and 0.3 parts by weight of catalyst, raise the temperature to 70°C and react for 4 hours, add 200 parts by weight of deionized water, after the precipitation is completely precipitated, add 30 parts by weight of nano aluminum hydroxi...

Embodiment 3

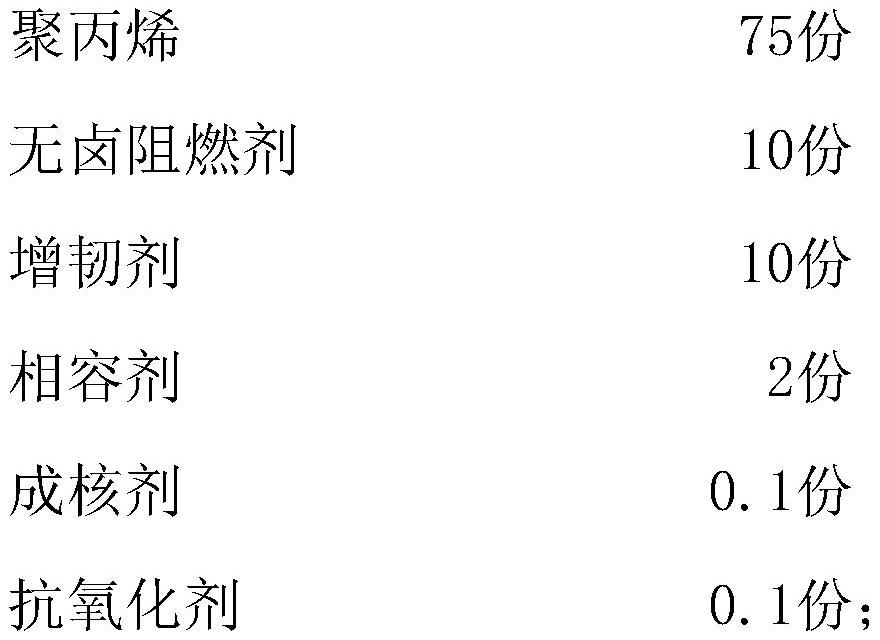

[0055] A polypropylene halogen-free flame-retardant material, comprising the following raw materials in parts by weight:

[0056]

[0057] Described toughening agent is made through the following steps:

[0058] (1) Add 55 parts by weight of nano silicon dioxide and 2 parts by weight of γ-aminopropyltriethoxysilane to 100 parts by weight of absolute ethanol, ultrasonically disperse for 2.5 hours, then centrifuge, wash and dry, Obtain modified nano silicon dioxide;

[0059] (2) Add 45 parts by weight of diphenylmethane diisocyanate and 25 parts by weight of modified nano-silica to 100 parts by weight of dimethylacetamide, raise the temperature to 60°C and stir for 2.5h, then drop to normal temperature , add 27.5 parts by weight of polytetrahydrofuran ether glycol and 0.2 parts by weight of catalyst, raise the temperature to 60 ° C and react for 3 hours, add 150 parts by weight of deionized water, after the precipitation is completely separated out, add 25 parts by weight of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com