Treatment device and treatment method for pyrohydrolysis sludge anaerobic digestion liquid

A technology of anaerobic digestion and treatment device, applied in heating water/sewage treatment, water/sludge/sewage treatment, water/sewage treatment, etc. To achieve the effect of good cleaning and recovery, high water quality and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

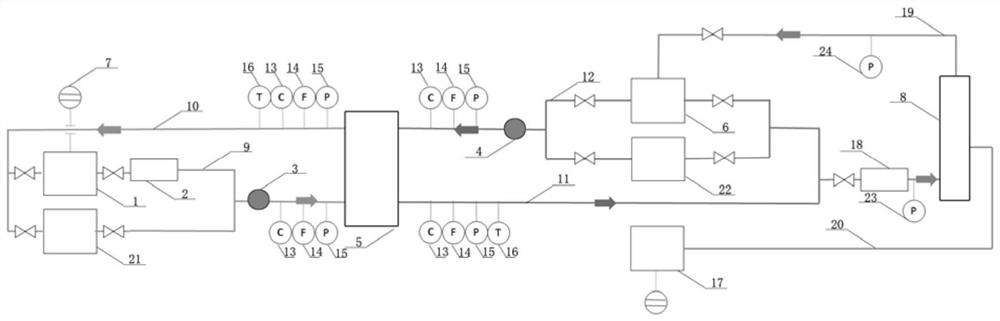

[0066] This embodiment provides a treatment device for thermally hydrolyzed sludge anaerobic digestion liquid, such as figure 1 As shown, the treatment device includes an independent or simultaneous forward osmosis unit, a high salt concentration unit 8, a water product tank 17 and a PLC control unit;

[0067] The high-salt concentration unit 8 is used to dynamically circulate the membrane treatment process of the forward osmosis unit;

[0068] The forward osmosis unit includes a raw material tank 1, a first filter 2, an infusion pump 3, a circulation pump 4, an FO membrane 5, a draw liquid tank 6 and a liquid level sensor 7; the two ends of the raw material tank 1 are respectively connected to There are a raw material liquid outlet pipe 9 and a raw material liquid concentrated water circulation pipe 10, the other end of the raw material liquid outlet pipe 9 and the other end of the raw material liquid concentrated water circulation pipe 10 are respectively connected to the ra...

Embodiment 2

[0073] This embodiment provides a treatment method for anaerobic digestion solution of thermally hydrolyzed sludge, which uses the treatment device for anaerobic digestion solution of thermally hydrolyzed sludge described in Example 1, such as figure 1 shown, including the following steps:

[0074] S1: Inject the thermally hydrolyzed sludge anaerobic digestion solution into the raw material tank 1, inject the drawing solution into the drawing solution tank 6, and turn on the infusion pump 3 and the circulation pump 4 After the thermal hydrolysis sludge anaerobic digestion liquid is filtered through the first filter 2, forward osmosis is carried out on the raw material liquid side of the FO membrane 5, and permeation is obtained on the draw liquid side of the FO membrane 5. Passing through the liquid, the raw material liquid concentrated water is obtained on the raw material liquid side of the FO membrane 5, and the raw material liquid concentrated water flows back into the raw...

Embodiment 3-7

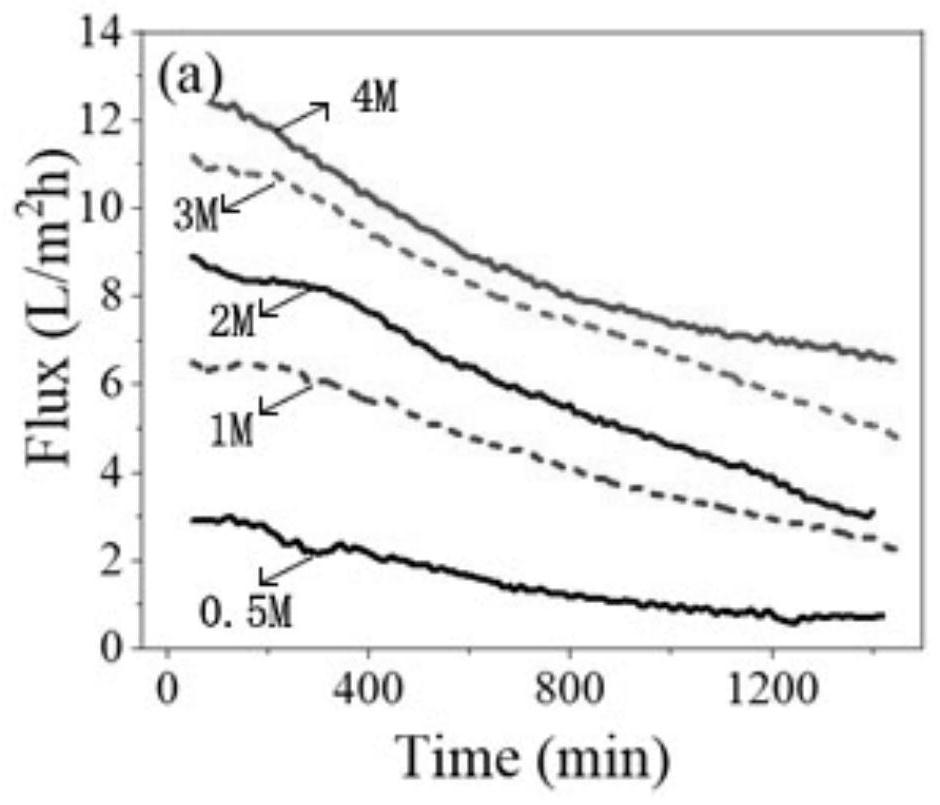

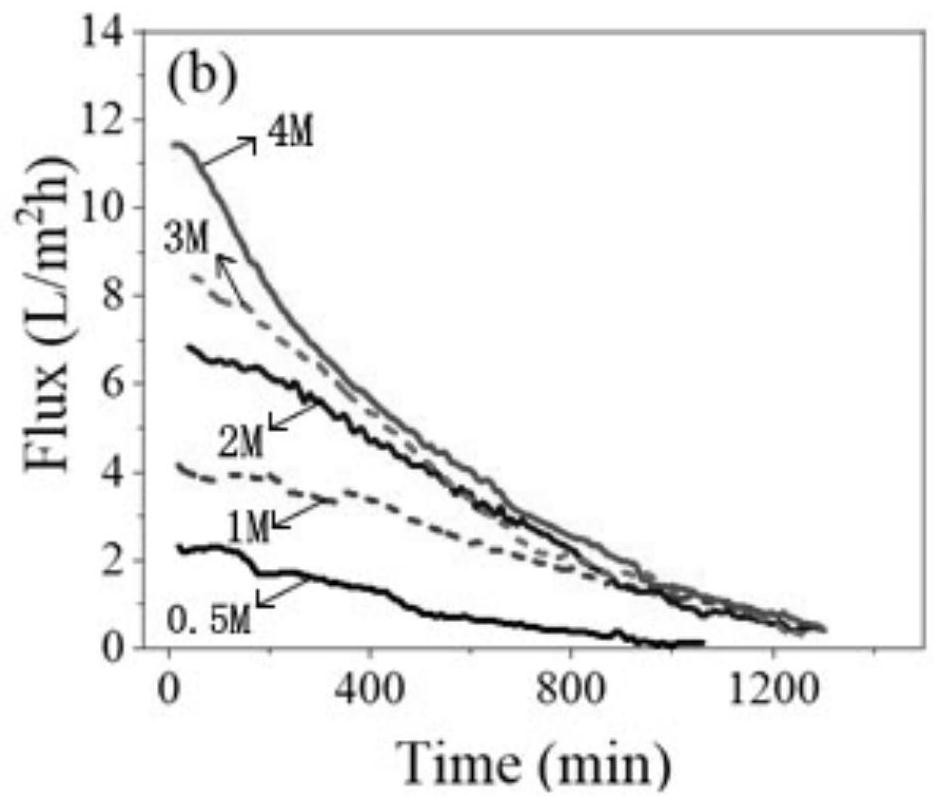

[0087] The drawing solution of Example 3-7 is a sodium chloride solution, and the concentration of the sodium chloride is 0.5mol / L, 1.0mol / L, 2.0mol / L, 3.0mol / L, 4.0mol / L in sequence;

[0088] The flow rate of the thermally hydrolyzed sludge anaerobic digestion solution injected into the raw material tank is 1.5L / min;

[0089] The temperature of the thermally hydrolyzed sludge anaerobic digestion solution is 25°C;

[0090] Other steps and conditions are identical with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com