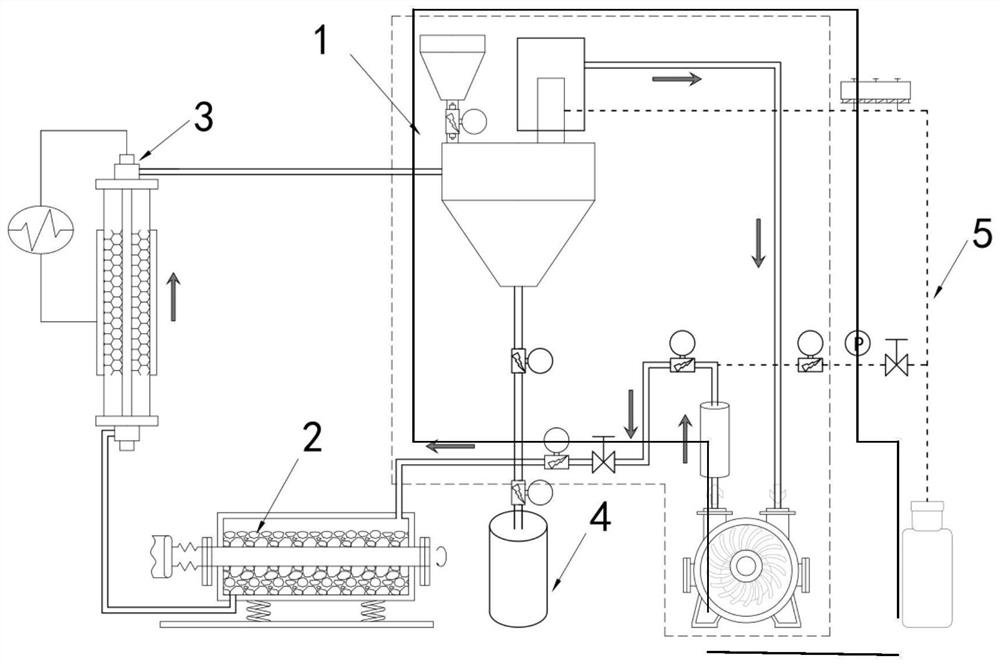

Continuous low-temperature plasma powder treatment and ball milling production device and method thereof

A technology of low-temperature plasma and production equipment, which is applied in the field of powder material processing and powder metallurgy, can solve the problems of poor treatment effect, unevenness, incomplete particle treatment, etc., and achieve the effect of reducing reaction activation energy and refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

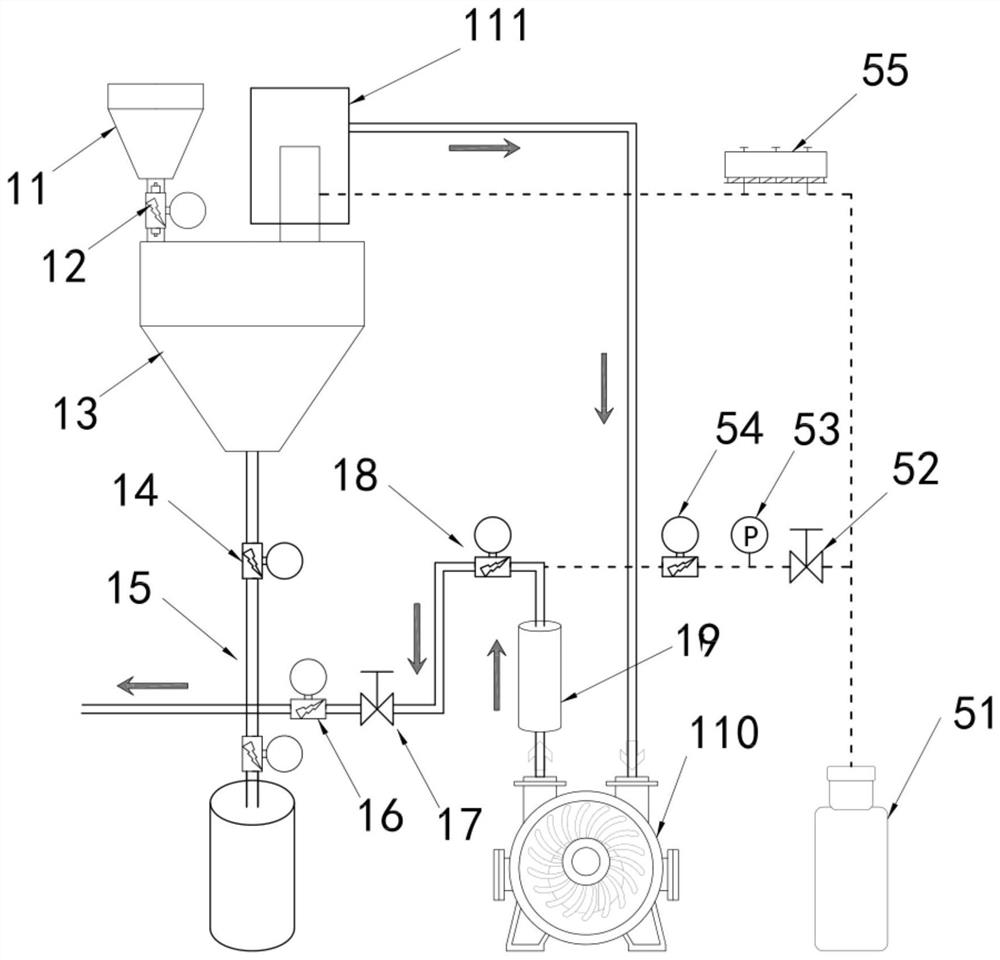

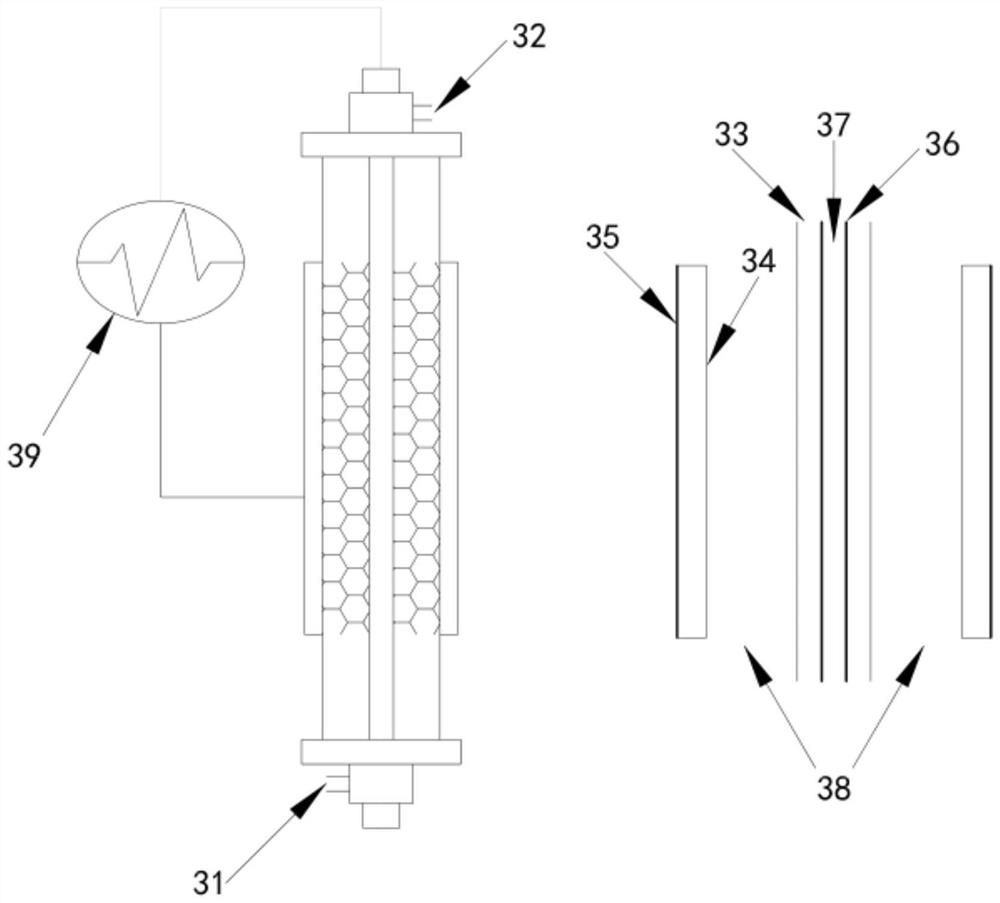

[0046] Step 1. Start the controllable atmosphere system first, evacuate the entire pipeline and ball mill chamber to below 1Pa, and then replace it with argon gas; secondly, start the vibrating ball mill and the powder circulation delivery pipeline system, and finally start the low-temperature plasma discharge pipeline and its cooling system.

[0047] Step 2. Feed 15 kg of ultra-fine Fe powder material into the feeding bin at one time, and automatically enter the temporary storage bin under the protection of argon through the feeding port of the feeding bin. The gas is separated from solid and gas in the backflushing system, and the remaining solid The material powder enters the material circulation system through the rotary feeding valve and the feeding pipeline; among them, the inner diameter of the powder circulation pipeline is selected as 35mm, the mass ratio of material powder and gas is 5:1, and the pressure of circulating gas and discharge gas is -0.3bar;

[0048] Step 3...

Embodiment 2

[0051] Step 1. Start the controllable atmosphere system first, evacuate the entire pipeline and ball mill chamber to below 1Pa, and then replace it with argon; secondly, start the powder circulation delivery pipeline system, and finally start the low-temperature plasma discharge pipeline and its cooling system.

[0052] Step 2. Feed 15 kg of ultra-fine Fe powder material into the feeding bin at one time, and automatically enter the temporary storage bin under the protection of argon through the feeding port of the feeding bin. The gas is separated from solid and gas in the backflushing system, and the remaining solid The material powder enters the material circulation system through the rotary feeding valve and the feeding pipeline; among them, the inner diameter of the powder circulation pipeline is selected as 60mm, the mass ratio of material powder and gas is 12:1, and the pressure of circulating gas and discharge gas is -0.1bar;

[0053] Step 3. The above-mentioned superfin...

Embodiment 3

[0057] Step 1. Start the controllable atmosphere system first, evacuate the entire pipeline and ball mill chamber to below 1Pa, and then replace it with argon gas; secondly, start the vibrating ball mill and the powder circulation delivery pipeline system, and finally start the low-temperature plasma discharge pipeline and its cooling system.

[0058] Step 2. Mix 8 kg of WO3 and graphite according to the carbon content of 20% by mass, pre-mill the above-mentioned mixed powder in a vibrating ball mill for 1 hour, and then feed it into the feeding bin at one time, and automatically pass through the feeding bin. The feed port enters the temporary storage bin under the protection of argon gas, and the gas realizes solid-gas separation in the blowback system, and the remaining solid material powder enters the material circulation system through the rotary feeding valve and the feeding pipeline; among them, the inner diameter of the powder circulation pipeline is selected to be 50 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com