Manufacturing method of TC-SAW filter

A TC-SAW and manufacturing method technology, applied in the direction of electrical components, impedance networks, etc., can solve the problems that the exposure and stripping process cannot be completed, the shape of the IDT electrode is not good enough, and the application of SAW products is limited, so as to improve the focus of lithography exposure , high yield, uniform width effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053]Hereinafter, the present invention will be described more specifically by referring to specific embodiments shown in the accompanying drawings. Various advantages and benefits of the present invention will become apparent to those of ordinary skill in the art upon reading the following detailed description of the specific embodiments. It should be understood, however, that the present invention may be embodied in various forms and should not be limited by the embodiments set forth herein. The following embodiments are provided for a more thorough understanding of the present invention. Unless otherwise specified, the technical terms or scientific terms used in the application shall have the ordinary meanings understood by those skilled in the art to which the application belongs.

[0054] In the following descriptions, terms such as "front, back, upper, lower" are only used to express relative positions without other limiting meanings.

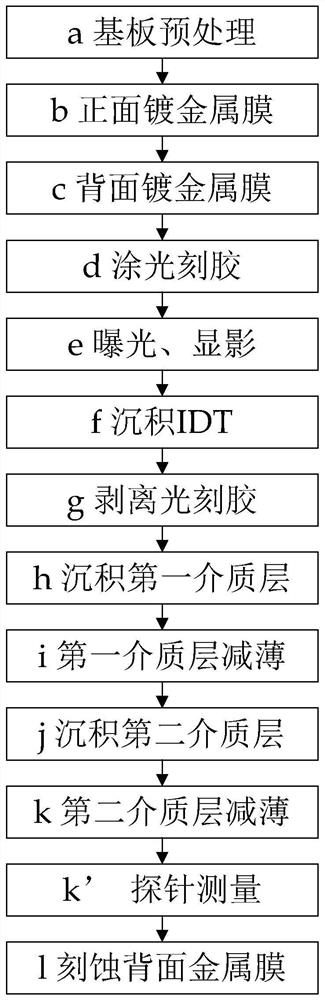

[0055] like figure 1 As shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com