Preparation method of non-lead copper-based halide scintillator film

A halide and scintillator technology, used in the field of X-ray detection and indirect detection, can solve the problems of reducing the resolution and sensitivity of X-ray imaging, difficult to store nanocrystals stably for a long time, and limiting the wide application of traditional scintillators. Best spectral matching, wide applicability, high light yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

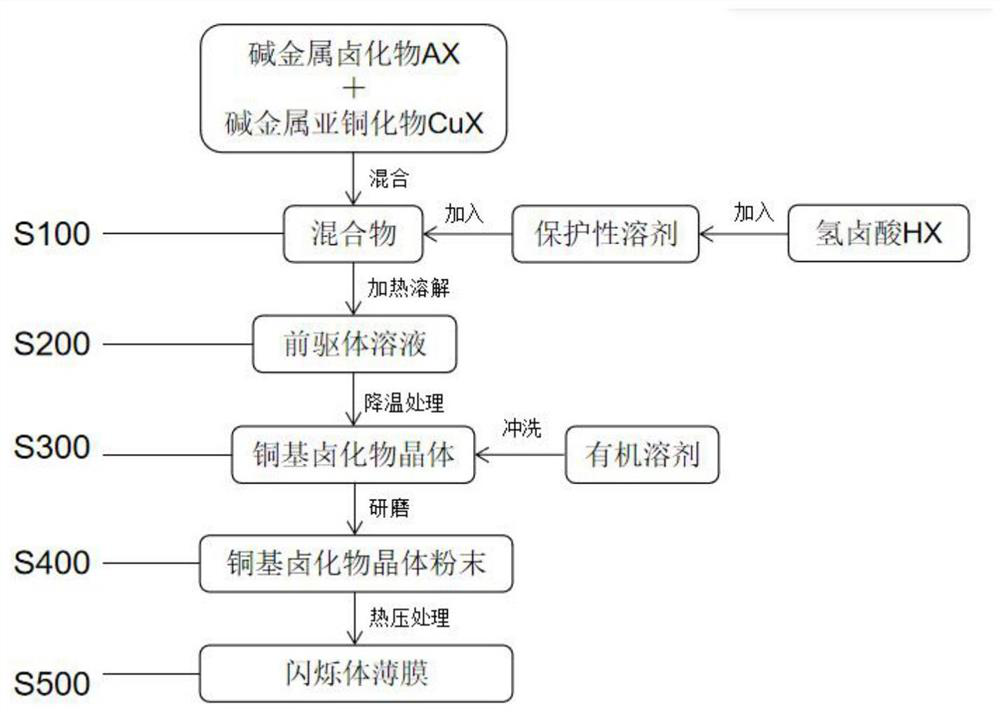

[0043] According to a typical embodiment of the present invention, a method of preparing a non-lead copper halide scintillator film, such as figure 1 The following steps are included:

[0044] S100 mixes the alkali metal halide AX and the alkali metal copper CUX, and hydrazine acid and reduction protectants are added to the mixture.

[0045] S200 heat dissolves the mixture to give the precursor solution, and the organic solvent is added thereto, and it is repeatedly rinsed.

[0046] The S300 obtains a copper-based halide scintillator crystal by vacuum drying.

[0047] The S400 copper-based halide scintillator crystal is polished into a powder.

[0048] The S500 is made into a copper-based halide scintillator crystal by hot press.

[0049] Among them, the reducing protective agent is hypophosphoric acid, and the organic solvent is isopropyl alcohol.

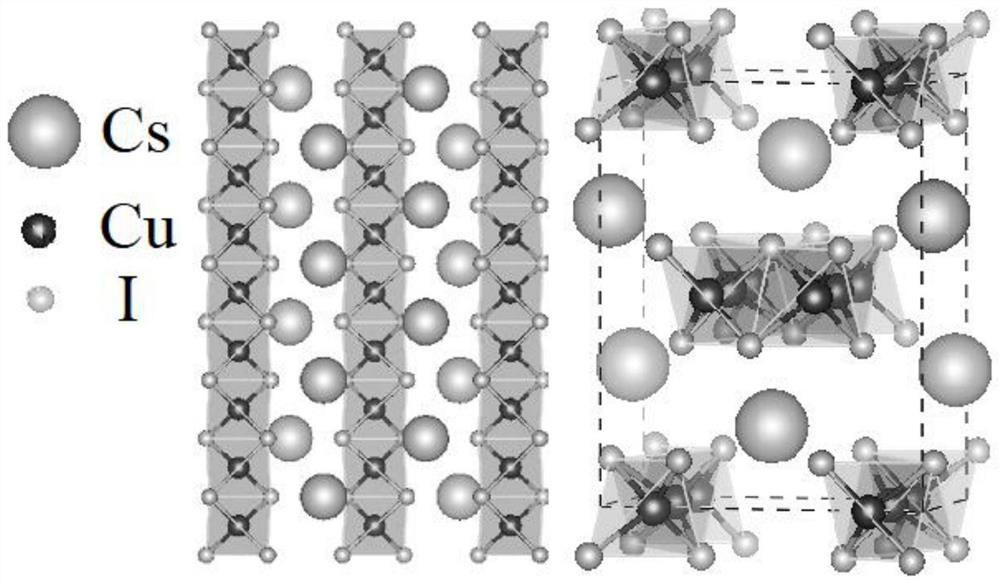

[0050] Such as figure 2 The preparation method of a non-lead copper-based halide scintillator film provided by the present inventio...

Embodiment 1

[0071] The RBCL and Cucl mixture were added to dilute hydrochloric acid, and the pellet was 0.16 mol / L, and then the mixed solution volume of 2% hypochlorlic acid was reduced, heated to form a transparent solution, and then 5 degrees Celsius per minute , Slow down to the solution, RB 2 Cucl 3 Due to the decrease in solubility, crystals were precipitated, rinsed with isopropanol and then dried in vacuo, thereby preparing RB 2 Cucl 3 Crystals.

[0072] RB will be made 2 Cucl 3 Crystals are polished into powder, and the powder particle size is less than 1 microns, and RB will 2 Cucl 3 The crystal powder is tiled on the quartz piece, then placed in the heat source heating, to be RB 2 Cucl 3 The crystal powder is melted, placing another preheated quartz sheet on the sparkle melt, and applies 0.1 MPa Pressure, cooling to normal temperature, removes quartz sheets, from RB 2 Cucl 3 Scintillator membrane.

Embodiment 2

[0074] The CSBR and CUBR mixture were added to the HBR solution, and the mixed solution was 0.16 mol / L, and then the mixed solution volume of 2% hypochlorous acid was reduced, and the transparent solution was heated, and the reduction of 5 degrees Celsius per minute, Slowly cool down for solution, CS 3 Cu 2 Br 5 Due to the decrease in solubility, the crystal is precipitated, flushing multiplexes with isopropanol and then drying in vacuo, thereby preparing CS 3 Cu 2 Br 5 Crystals.

[0075] CS will be made 3 Cu 2 Br 5 The crystal grinding into a powder, the powder particle size is less than 1 micron, and the CS will be 3 Cu 2 Br 5 The crystal powder is tiled on the quartz piece, and then placed in a heat source heating, to be CS 3 Cu 2 Br 5 The crystal powder is melted, and the other preheated aspage-resistant sheet is placed on the sparkle melt, and 0.4 MPa pressure is applied, after cooling to normal temperature, remove the quartz sheet, from CS 3 Cu 2 Br 5 Scintillator membrane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com