Phosphorus-containing flame retardant with amino group as well as preparation method and application of flame retardant

A flame retardant and amine-based technology, which is applied in the field of phosphorus-containing flame retardants and their preparation, can solve the problems of inability to achieve environmentally friendly flame retardants, pollute the environment, and fail to achieve safety and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

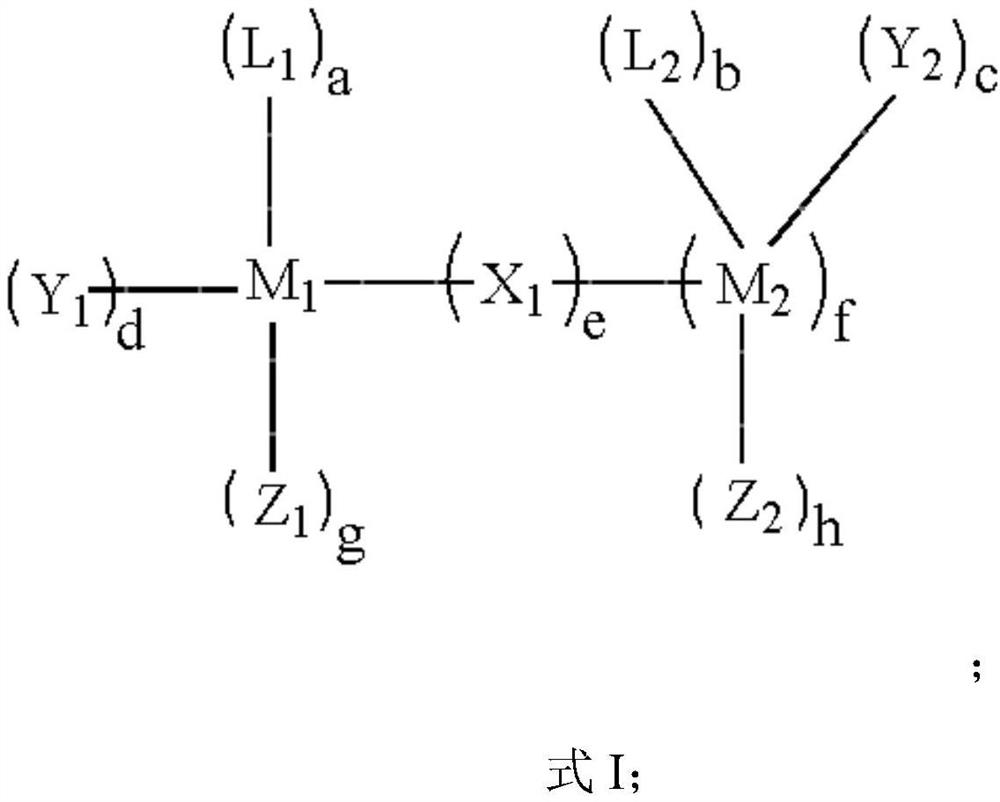

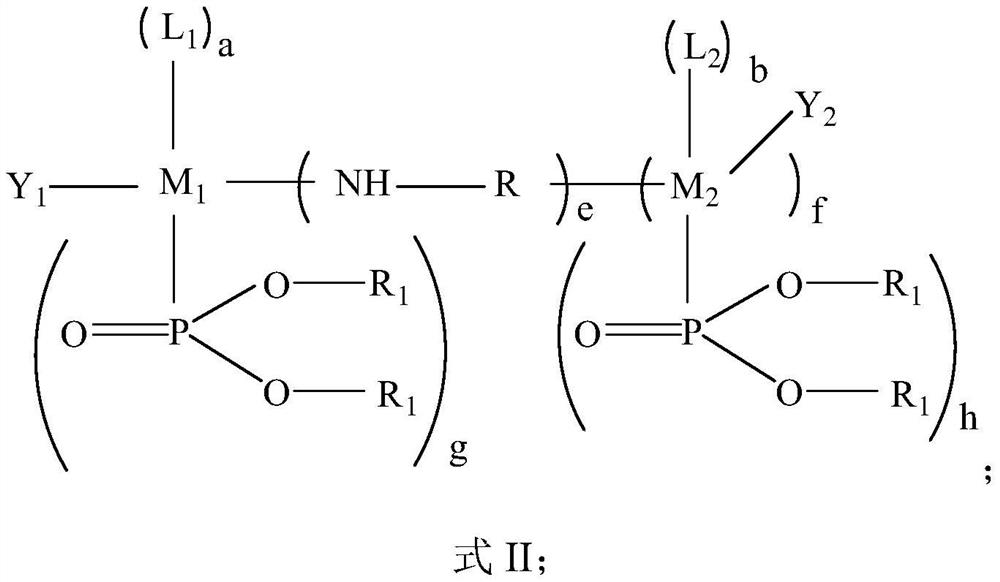

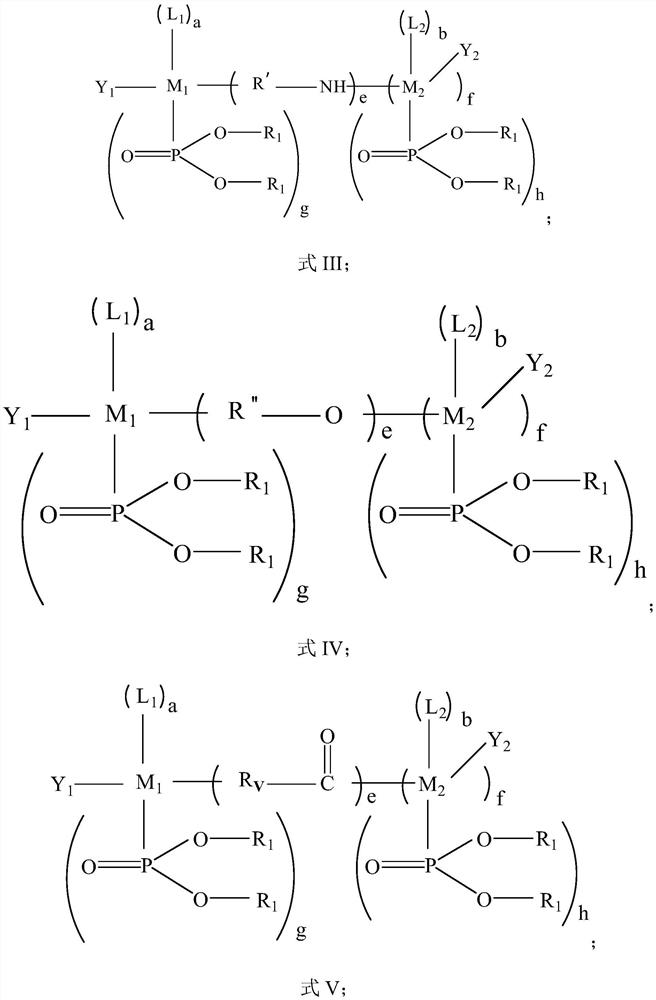

Method used

Image

Examples

preparation example 1

[0077] A phosphorus-containing flame retardant with an amine group, the structure is as follows:

[0078]

[0079] The preparation method is as follows:

[0080] In a three-necked flask equipped with magnetic stirring and a thermometer, add 1 mol of diethylenetriamine and 2 mol of dimethyl hydroxymethyl phosphite, 200 mL of ethanol and 0.1 mol of sodium hydroxide, 0.1 g of DMAP, heat up to ethanol reflux, and react for 12 hours. Then add hydrochloric acid until the pH is 7, filter and wash to remove impurities, and obtain the phosphorus-containing flame retardant with the above structure.

[0081] 1 H NMR (400MHz, DMSO-d6): δ=3.49-3.51(d,12H,-P-O-CH 3 ),3.03-3.06(s,4H,-P-C H 2 -),2.66-2.69(t,8H,-NH-C H 2 -C H 2 -NH-),2.11-2.14(s,3H,-NH-).

preparation example 2

[0083] A phosphorus-containing flame retardant with an amine group, the structure is as follows:

[0084]

[0085] The preparation method is as follows:

[0086] Add 1 mol of diethylenetriamine and 1 mol of dimethyl hydroxymethyl phosphite, 200 mL of ethanol, 0.1 mol of sodium hydroxide, and 0.1 g of DMAP into a three-necked flask equipped with magnetic stirring and a thermometer, heat up to ethanol reflux, and react for 12 hours. Then add hydrochloric acid until the pH is 7, filter and wash to remove impurities, and obtain the phosphorus-containing flame retardant with the above structure.

[0087] 1 H NMR (400MHz, DMSO-d6): δ=5.00-5.03(s, 2H, -N H 2 ),3.48-3.50(d,6H,-P-O-CH 3 ),3.03-3.06(s,2H,-P-C H 2 -),2.85-2.88(t,2H,-NH-CH 2 -C H 2 -NH 2 ),2.65-2.68(t,2H,-NH-C H 2 -CH 2 -NH 2 ),2.51-2.55(s,4H,-NH-C H 2 -C H 2 -NH-).

preparation example 3

[0089] A phosphorus-containing flame retardant with an amine group, the structure is as follows:

[0090]

[0091] The preparation method is as follows:

[0092] (1) Under a nitrogen atmosphere, put 200mL glacial acetic acid, 0.5mol dimethyl phosphite and 0.5mol maleic acid into a three-port 500mL glass reactor with a stirring device and stir. At a stirring temperature of 60°C, 0.5mmol The Pb catalyst was dissolved in 20mL of glacial acetic acid, then added dropwise to the reaction system, reacted for 12h, and then separated the product;

[0093] 1 H NMR (400MHz, DMSO-d6) δ = 13.52-13.54 (s, 1H, -CH-CO-O H ),12.98-13.00(s,1H,-CH 2 -CO-O H ),3.47-3.49(d,6H,-P-O-C H 3 ),2.85-2.90(t,1H,-CH-),2.78-2.81(d,2H,-C H 2 -).

[0094] (2) Mix 1 mol of the product obtained in step (1), 2 mol of thionyl chloride and 200 mL of chloroform, react at reflux temperature, then add 1 mol of ethylenediamine and 0.1 mol of triethylamine to react for 30 minutes to obtain product B;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com