Synthetic fiber rope

A synthetic fiber and crane technology, applied in the field of crane equipment, can solve problems such as not being able to meet the fire prevention requirements of synthetic fiber ropes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

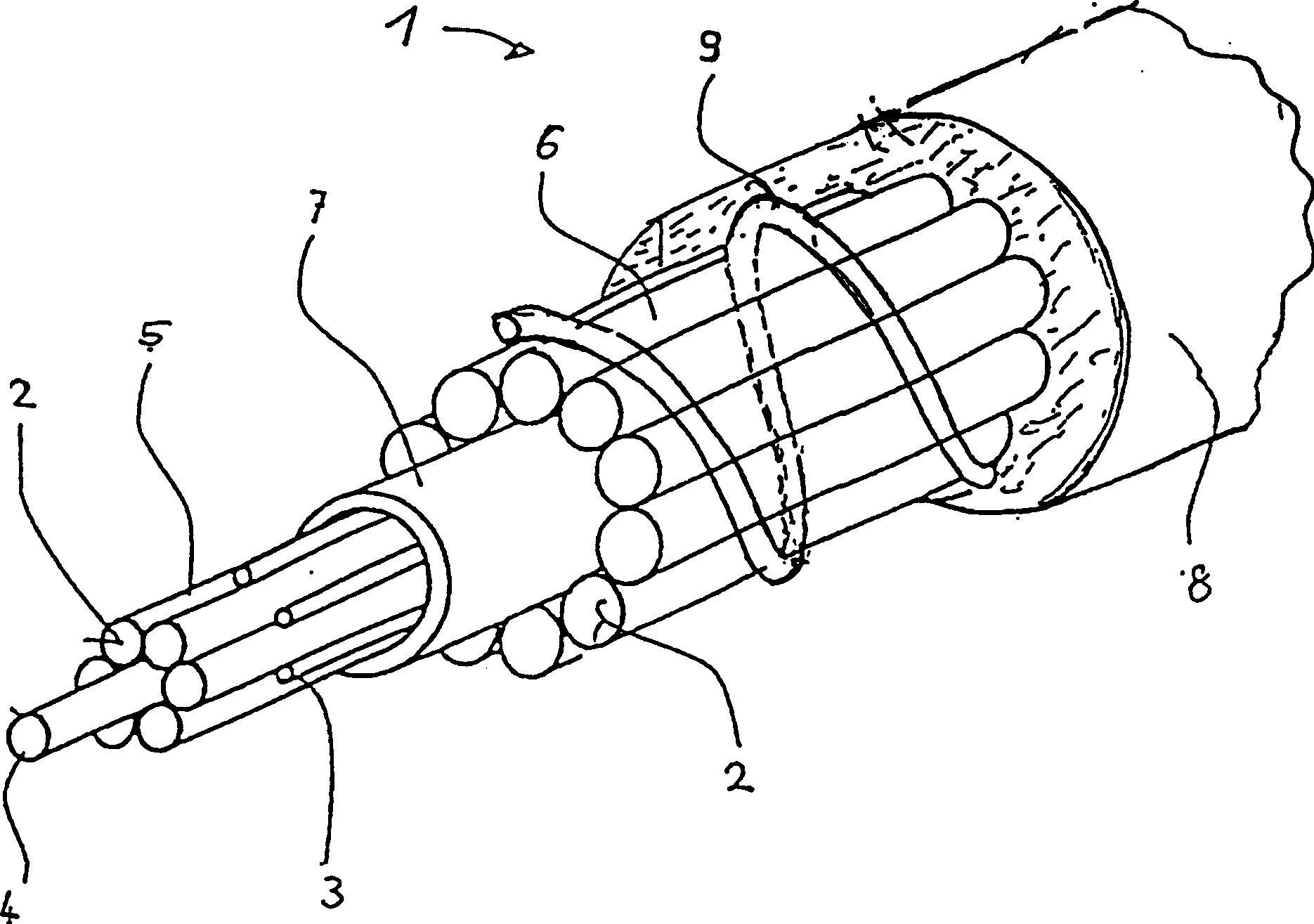

[0017] figure 1 The perspective view of the figure shows that the aramid fiber strands 2 and the filling strands 3 together form a sheathed aramid fiber rope 1 arranged around a core 4. Between the inner strand layer 5 and the outermost strand layer 6 is formed a wear-reducing intermediate sheath 7 which is preferably irregularly contoured. The outermost strand layer 6 is covered by a cord sheath 8, preferably polyurethane or polyamide. A thinner wire 9 is helically wound on the outermost strand layer 6 along the entire length of the cord. The cord sheath 8 is extruded over the wire 9 so that it is embedded in the cord sheath material and covered by it.

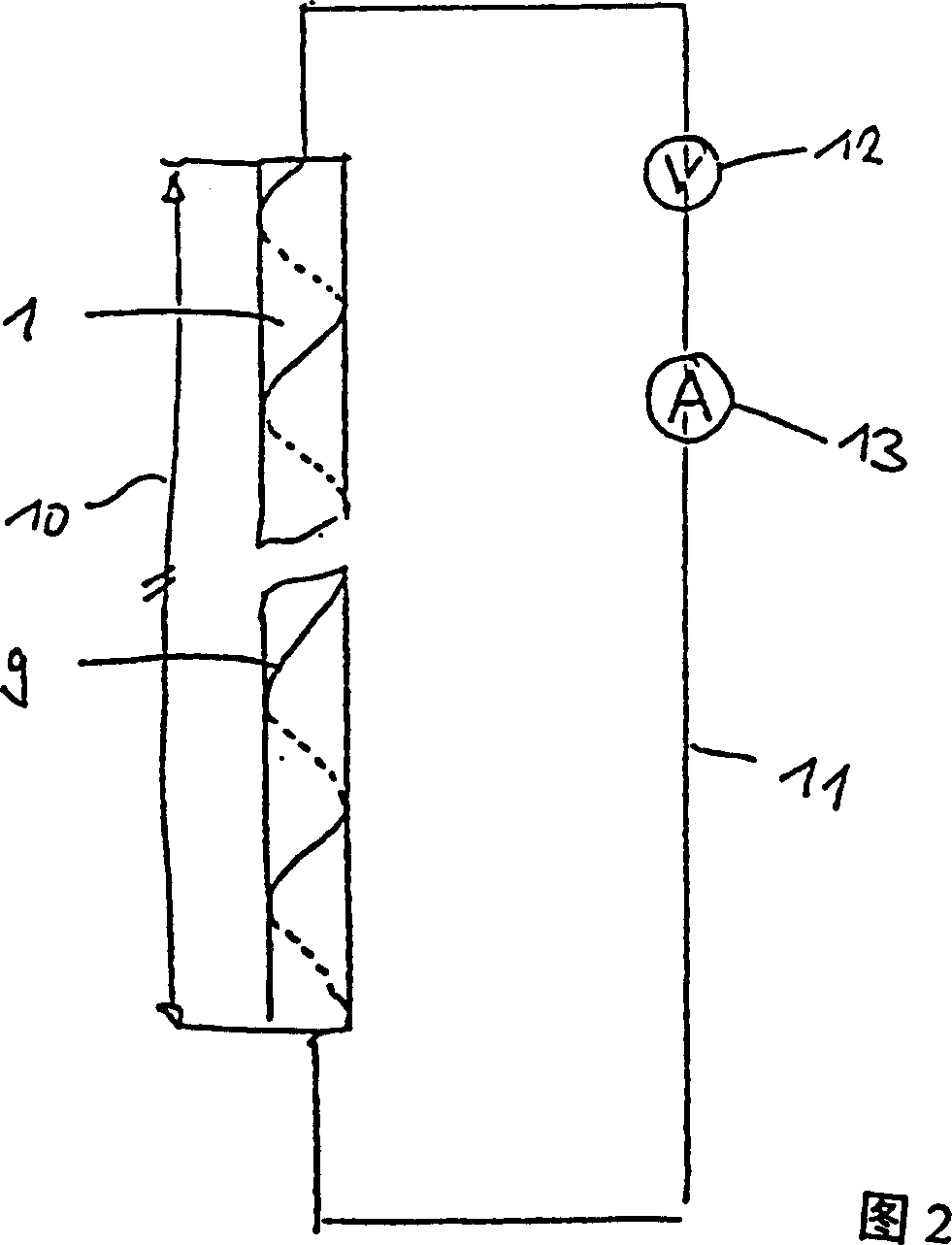

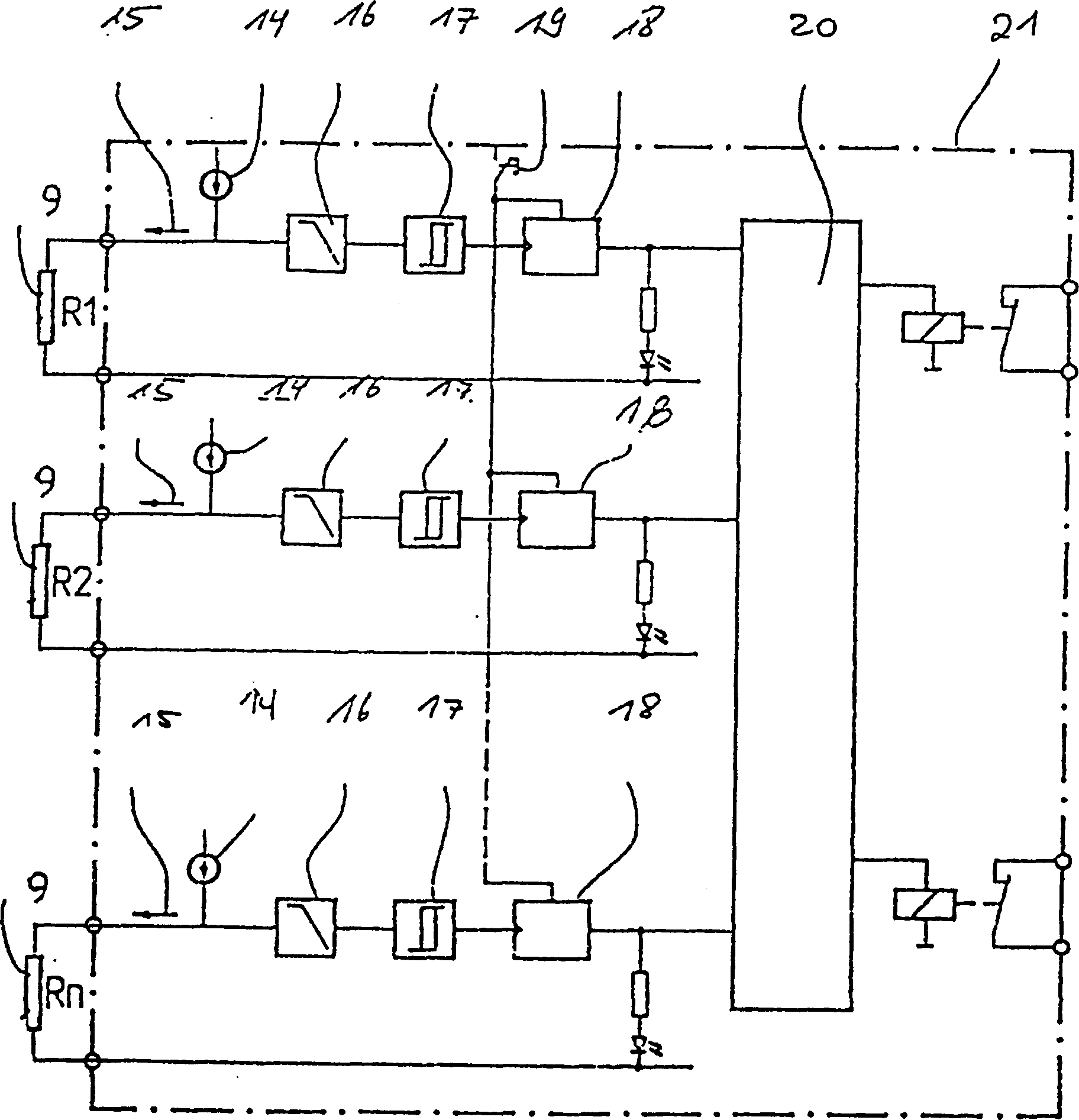

[0018] The wire 9 consists of a metal alloy and is electrically conductive. Its resistance increases with temperature. The resistance is continuously sensed using a sense control device described further below. The composition of the alloy is chosen so that the wire melts in the range of 100 to 120 degrees Celsius. Pref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com