Composite inorganic board and its making method

A manufacturing method and technology of inorganic boards, which are applied in chemical instruments and methods, synthetic resin layered products, lamination devices, etc., can solve the problems of environmental noise pollution, rough surface, low grade, etc., and achieve simple process, simple operation, The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

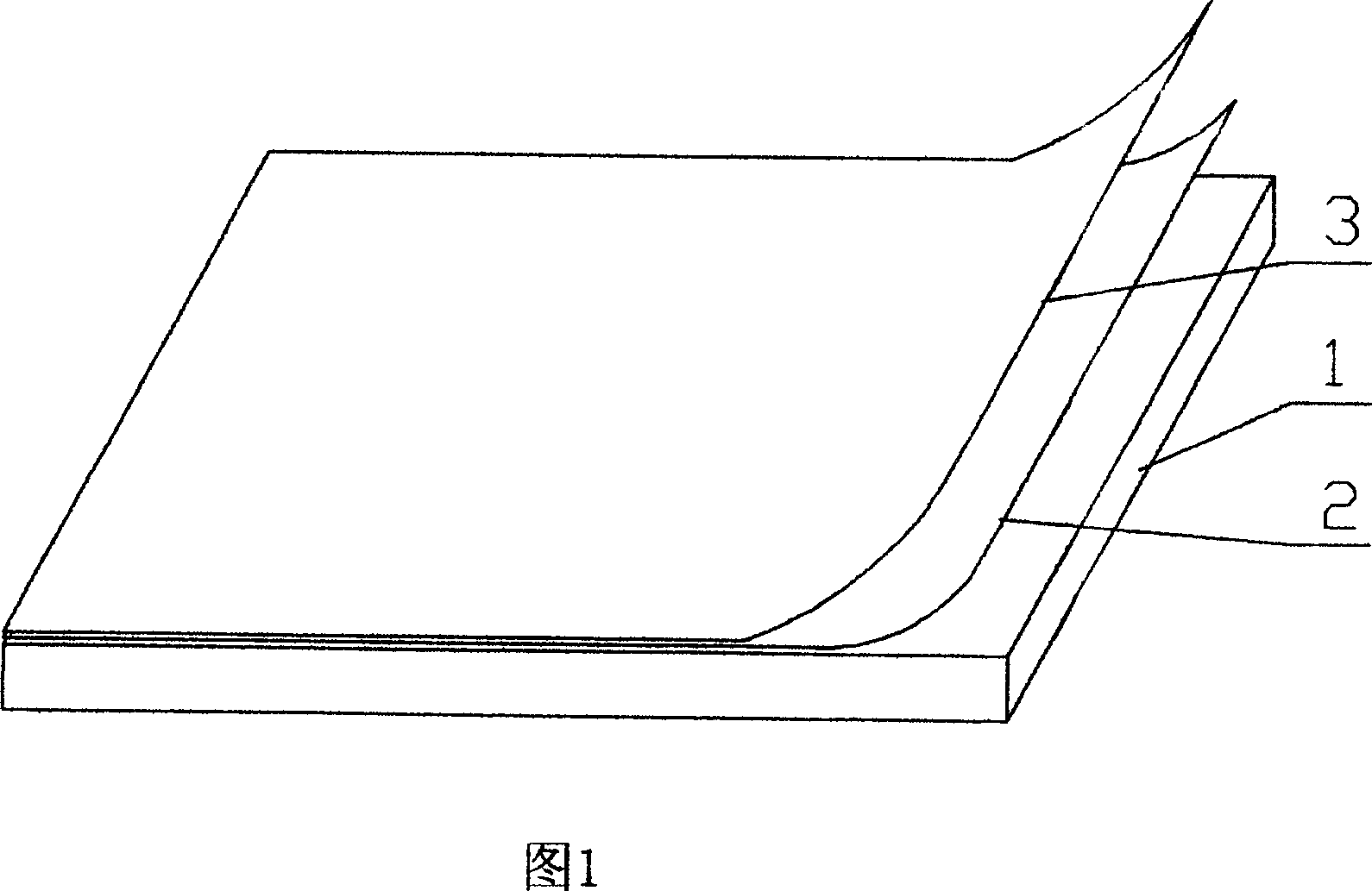

[0020] As shown in Figure 1, a composite inorganic board includes a layer of glass magnesium board base layer 1, the surface of the glass magnesium board base layer is rough, has pinholes and defects, etc., and the surface that needs vacuum suction on the glass magnesium board base layer A layer of paper layer 2 with a weight of 30 grams is pasted on the top. The thickness of the paper layer 2 is 0.15 mm. A glue layer is sprayed around the product, and a layer of PVC layer 3 is vacuum formed on the paper layer 2.

[0021] The present invention is not limited to the above-mentioned embodiments, and the inorganic boards can be glass magnesium boards, wood and stone fiber boards, calcium silicate boards, gypsum boards, rock wool composite boards, or polyurethane rigid foam boards. The inorganic sheet can be two or more layers, and interlayers such as sound insulation and heat insulation foam can also be provided between the interlayers of the inorganic sheet, and the transition la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com