Petroleum fracturing propping agent as well as preparation method and application thereof

A fracturing proppant and petroleum technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problem of insufficient compressive strength of quartz sand proppant and preparation cost of bauxite ceramsite proppant Advanced problems, to achieve the effect of reducing energy consumption, good sintering strength, and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

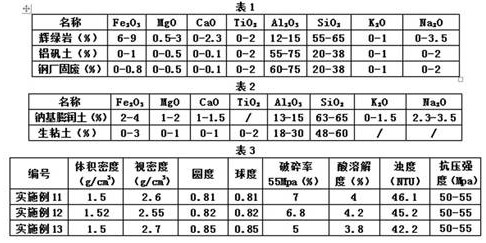

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: The petroleum fracturing proppant, the raw materials are in parts by weight, including 65 to 70 parts of diabase, 10 to 12 parts of temperature regulator, 18 to 20 parts of viscosity regulator and 3 parts of auxiliary materials To 5 parts, obtain according to the following steps:

[0030] (1) Put the required amount of diabase with a particle size of less than 50mm, temperature regulator, viscosity regulator and auxiliary materials in the silo, and then send it to the vertical mill for processing to 400 mesh powder, and then turn it into a ball machine;

[0031] (2) Control the speed of the ball forming machine from 30rpm to 50rpm, add water with a weight of 12% to 15% of the total weight of the powder into the ball forming machine, keep the speed constant, and form a spherical material after running for 25min to 40min;

[0032] (3) Control the drying temperature at 80°C to 350°C, the drying time is 60min to 100min, and the spherical material is dried unt...

Embodiment 2

[0034] Embodiment 2: The petroleum fracturing proppant, the raw material includes 65 parts or 70 parts of diabase, 10 parts or 12 parts of temperature regulator, 18 parts or 20 parts of viscosity regulator and 3 parts of auxiliary materials in parts by weight. Or 5 parts, according to the following steps to get:

[0035] (1) Put the required amount of diabase with a particle size of less than 50mm, temperature regulator, viscosity regulator and auxiliary materials in the silo, and then send it to the vertical mill for processing to 400 mesh powder, and then turn it into a ball machine;

[0036] (2) Control the speed of the ball forming machine to 30rpm or 50rpm, add water with a weight of 12% or 15% of the total weight of the powder into the ball forming machine, keep the speed constant, and run for 25min or 40min to form spherical materials;

[0037] (3) Control the drying temperature at 80°C or 350°C, and the drying time at 60min or 100min. Dry the sphere material until the...

Embodiment 3

[0041] Example 3: As an optimization of the above example, the diabase components include silicon dioxide, aluminum oxide and iron oxide. The proportion of diabase in the present invention is 65% to 70%. It mainly utilizes its acid resistance, and it has a certain viscosity when processed to 400 mesh, and its bulk density is 2.9g / cm 3 to 3.0g / cm 3 , can be used to adjust the density of the present invention. Diabase has the characteristics of lower sintering temperature than bauxite and better sintering strength.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com