Method for simply and efficiently preparing multicolor all-solid-state electrochromic device

An electrochromic device and electrochromic technology, applied in instruments, nonlinear optics, optics, etc., can solve problems such as easy leakage, electrolyte deterioration, and difficult sealing, and achieve increased wetting fusion, improved stability, and strong bonding. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A simple and efficient method for preparing multicolor all-solid-state electrochromic devices:

[0043] (1) The FTO conductive glass (produced by Shenzhen Huanan Xiangcheng Technology Co., Ltd.) was ultrasonically cleaned in deionized water for 20 minutes. After cleaning, it was placed in a 60 ℃ oven to dry for use. Before the hydrothermal reaction, it was treated in a plasma cleaning machine. 5 minutes;

[0044] (2) Dissolve 0.287 g of lithium bistrifluoromethanesulfonimide in 1 mL of polyethylene glycol diacrylate, fully stir until dissolved, and then add 10 μL of 2-hydroxy-2-methylpropiophenone and stir evenly to form Liquid polymer electrolyte, ready for use;

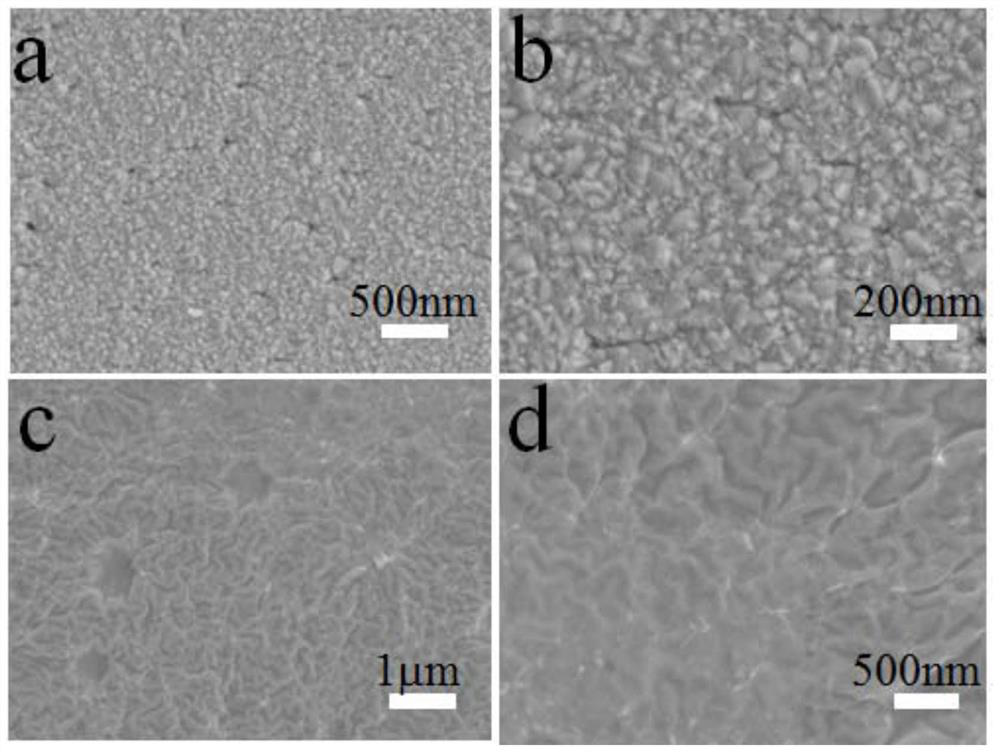

[0045] (3) First, a multi-color electrochromic film with a tin dioxide / vanadium pentoxide core-shell structure was prepared on a conductive substrate by combining the hydrothermal method and the electrodeposition method as the electrochromic layer, and then the FTO as the ion storage layer was used as the el...

Embodiment 2

[0050] A simple and efficient method for preparing multicolor all-solid-state electrochromic devices:

[0051] (1) The FTO conductive glass (produced by Shenzhen Huanan Xiangcheng Technology Co., Ltd.) was ultrasonically cleaned in deionized water for 20 minutes. After cleaning, it was placed in a 60 ℃ oven to dry for use. Before the hydrothermal reaction, it was treated in a plasma cleaning machine for 5 minutes. minute;

[0052] (2) Dissolve 0.287g of lithium bistrifluoromethanesulfonimide in 1mL of polyethylene glycol diacrylate, stir fully until dissolved, then add 10μL of 2-hydroxy-2-methylpropiophenone and stir evenly to form a liquid The polymer electrolyte, ready to use;

[0053] (3) First, a multi-color electrochromic film with a tin dioxide / vanadium pentoxide core-shell structure was prepared on a conductive substrate by combining the hydrothermal method and the electrodeposition method as the electrochromic layer, and then the FTO as the ion storage layer was used ...

Embodiment 3

[0058] A simple and efficient method for preparing multicolor all-solid-state electrochromic devices:

[0059] (1) The FTO conductive glass (produced by Shenzhen Huanan Xiangcheng Technology Co., Ltd.) was ultrasonically cleaned in deionized water for 20 minutes. After cleaning, it was placed in a 60 ℃ oven to dry for use. Before the hydrothermal reaction, it was treated in a plasma cleaning machine for 5 minutes. minute;

[0060] (2) Dissolve 0.287g of lithium bistrifluoromethanesulfonimide in 1mL of polyethylene glycol diacrylate, stir fully until dissolved, then add 10μL of 2-hydroxy-2-methylpropiophenone and stir evenly to form a liquid The polymer electrolyte, ready to use;

[0061] (3) First, a multi-color electrochromic film with a tin dioxide / vanadium pentoxide core-shell structure was prepared on a conductive substrate by combining the hydrothermal method and the electrodeposition method as the electrochromic layer, and then the FTO as the ion storage layer was used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com