Multifunctional spray pipe of snow blowing vehicle

A multi-functional, snow blower technology, which is applied in snow surface cleaning, construction, cleaning methods, etc., can solve the problems of fixed nozzle design, low snow removal efficiency, and no way to adjust nozzle holes in different road environments, so as to maintain stability, The effect of changing the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

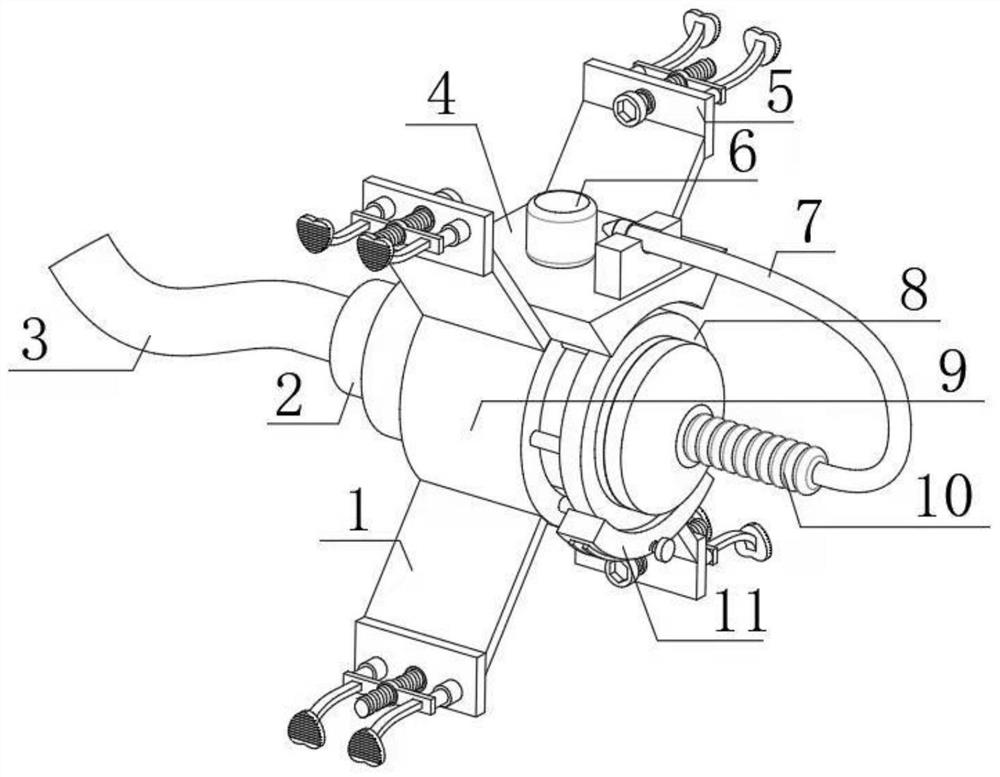

[0028] refer to Figure 1-5 , a multifunctional nozzle of a snow blower, comprising a main body frame 9, an annular chute is formed on the inner wall of the circumference of the main body frame 9, the inner wall of the annular chute is fixedly connected with an annular slide rail, and the inner wall of the annular slide rail is slidably connected with etc. The slider 18 distributed at a distance, the outer wall of one side of the slider 18 is fixedly connected with the same main body tube 14, one end of the main body tube 14 is fixedly connected with a fixed rod equidistantly distributed, and one end of the fixed rod is fixedly connected with the same ring frame 8. The ring frame 8 is slidingly socketed on the outer wall of the main body tube 14 near one end, and the inner wall of the main body tube 14 near one end is provided with leak holes 15 distributed equidistantly. The leak holes 15 communicate with the inside of the ring frame 8, and the ring frame One side outer wall ...

Embodiment 2

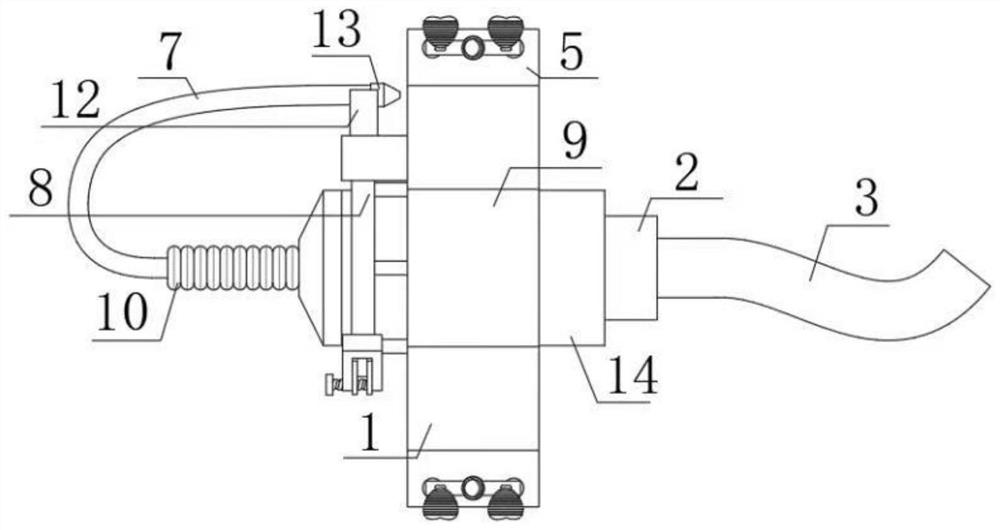

[0038] refer to Figure 6 , a multifunctional nozzle of a snow blower, comprising a main body frame 9, an annular chute is formed on the inner wall of the circumference of the main body frame 9, the inner wall of the annular chute is fixedly connected with an annular slide rail, and the inner wall of the annular slide rail is slidably connected with etc. The slider 18 distributed at a distance, the outer wall of one side of the slider 18 is fixedly connected with the same main body tube 14, one end of the main body tube 14 is fixedly connected with a fixed rod equidistantly distributed, and one end of the fixed rod is fixedly connected with the same ring frame 8. The ring frame 8 is slidingly socketed on the outer wall of the main body tube 14 near one end, and the inner wall of the main body tube 14 near one end is provided with leak holes 15 distributed equidistantly. The leak holes 15 communicate with the inside of the ring frame 8, and the ring frame One side outer wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com