Tin brass welding wire and preparation method thereof

A technology of tin brass welding wire and range, applied in welding equipment, welding medium, manufacturing tools, etc., can solve the problems of tin brass welding wire processing technology is immature, processing technology is not complete, can not meet production needs, etc., to achieve processing effect Good, complete processing technology, high tensile strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

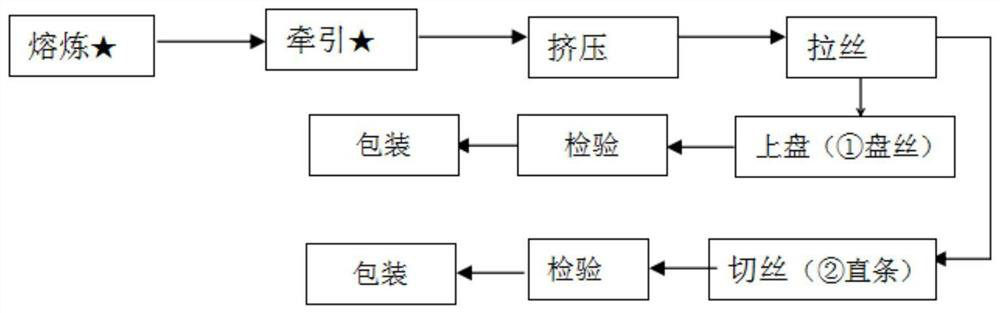

[0047] A method for preparing tin-brass welding wire, the process steps comprising:

[0048] Step S1, melting: (1) using raw materials; main materials: electrolytic copper, zinc ingots, tin, auxiliary materials: slag cleaning agent, silicon;

[0049] (2) Feeding sequence: copper, silicon, zinc, tin;

[0050] (3) When the added material is melted and kept warm, take a sample test and adjust the composition according to the data of the test sheet;

[0051] (4) Raise the temperature after the ingredients are adjusted;

[0052] (5) Add an appropriate amount of slag cleaning agent after the temperature rise is complete, and then start to remove the ash and remove the slag. During the ash removal process, the copper ash spoon is required to stay at the furnace mouth for about 20 seconds when the ash is removed from the copper water, so as to ensure that the copper in the ash All the water flows into the furnace;

[0053] (6) Measure the temperature in the furnace after the ash re...

Embodiment 1

[0062] The raw materials are batched according to the ratio, and the batching sequence is: copper, silicon, zinc, tin, and the materials are added for melting. When keeping warm, sampling and testing are carried out, and the ingredients are adjusted according to the data of the test sheet. After the ingredients are adjusted, the temperature is raised. , the method of judging the temperature increase without ash and slag removal is to look at the direction of the pointer of the furnace ammeter. When the pointer reverses violently, the temperature has reached the state of temperature increase. In the process of ash removal, the copper ash spoon is required to stay at the furnace mouth for about 20 seconds when the ash is removed from the copper water, so as to ensure that all the copper water in the ash flows into the furnace. When the ash removal is complete Measure the temperature in the furnace. If the temperature is not enough, you need to raise the temperature again. The met...

Embodiment 2

[0064]The raw materials are batched according to the ratio, and the batching sequence is: copper, silicon, zinc, tin, and the materials are added for melting. When keeping warm, sampling and testing are carried out, and the ingredients are adjusted according to the data of the test sheet. After the ingredients are adjusted, the temperature is raised. , the method of judging the temperature increase without ash and slag removal is to look at the direction of the pointer of the furnace ammeter. When the pointer reverses violently, the temperature has reached the state of temperature increase. In the process of ash removal, the copper ash spoon is required to stay at the furnace mouth for about 20 seconds when the ash is removed from the copper water, so as to ensure that all the copper water in the ash flows into the furnace. When the ash removal is complete Measure the temperature in the furnace. If the temperature is not enough, you need to raise the temperature again. The meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com