Purification device and method for pyrolysis non-condensable gas of waste tires

A technology for purifying device and waste tires, applied in chemical instruments and methods, combination devices, separation methods, etc., can solve the problems of not mentioning the basis of flue gas composition index, the basis of flue gas combustible gas, not mentioning flue gas composition index, etc. , to achieve the effect of complete waste gas treatment process, meet the requirements of thermal energy utilization, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

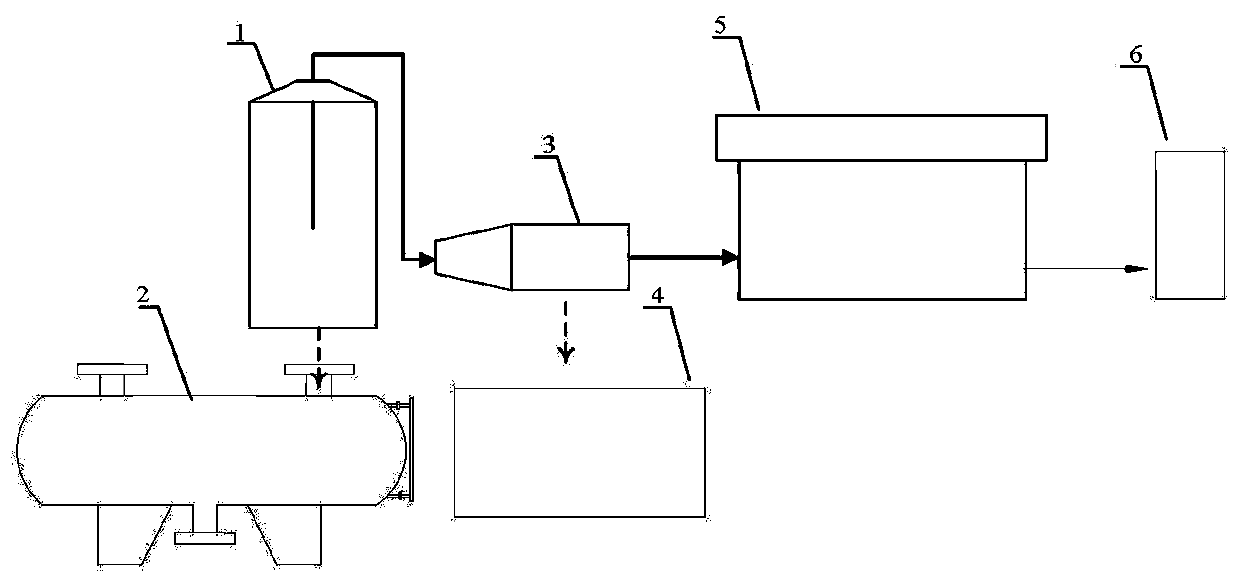

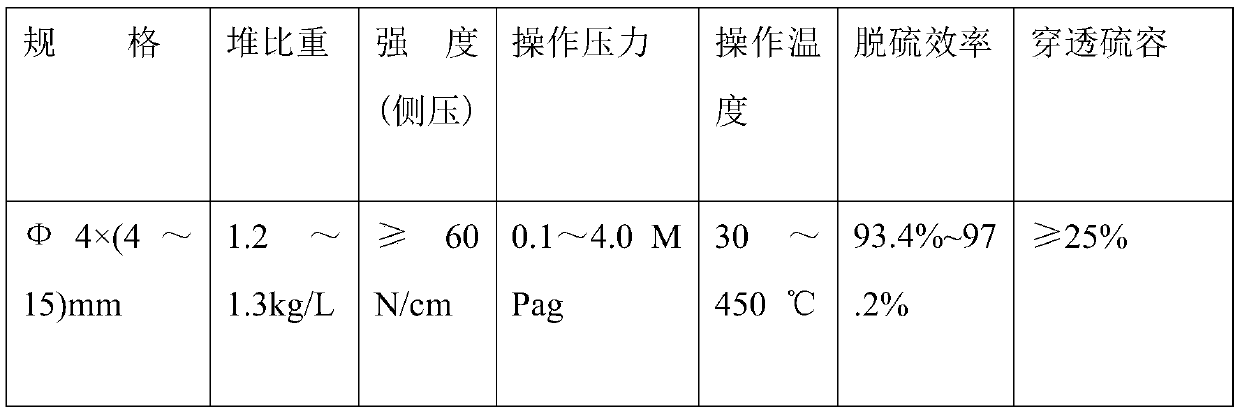

[0037] A method for purifying non-condensable gas by pyrolysis of waste tires described in this embodiment comprises the following steps:

[0038] The crude non-condensable gas from waste tire pyrolysis enters the electric tar collector to capture and remove a small amount of oil doped in the non-condensable gas. The working voltage is 34kV, and the captured oil is sent to the tar storage tank for collection; Impurities and moisture in condensed gas; non-condensable gas after dehumidification and impurity removal passes through a box-type desulfurization device, using nano-zinc oxide as a desulfurizer to desulfurize at room temperature, and the removal rate of hydrogen sulfide in non-condensable gas after desulfurization can reach 97.2% , the content is 5mg / m 3 . Example 1 meets the hydrogen sulfide content requirements of natural gas II.

[0039] project Non-condensable gas after purification Natural gas class II Hydrogen sulfide / (mg / m 3 )

Embodiment 2

[0041] A method for purifying noncondensable gas by pyrolysis of waste tires described in this embodiment comprises the following steps: the crude noncondensable gas from pyrolysis of waste tires enters an electric tar catcher to capture and remove a small amount of oil doped in the noncondensable gas, The working voltage is 32kV, and the captured oil is sent to the tar storage tank for collection; after that, the impurity and moisture in the non-condensable gas are filtered out with a filter; the non-condensable gas after dehumidification and impurity is passed through a box-type desulfurization device, and nano-zinc oxide is used As a desulfurizer, desulfurize at room temperature, the removal rate of hydrogen sulfide in non-condensable gas after desulfurization can reach 93.4%, and the content is 12mg / m 3 .

[0042] Example 2 meets the hydrogen sulfide content requirements of natural gas class II.

[0043] project Non-condensable gas after purification Natural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com