Water-soluble low-modulus acrylic resin adhesive and preparation method thereof

An acrylic resin, water-soluble technology, applied in adhesive types, ester copolymer adhesives, etc., can solve problems such as inability to obtain products, achieve small molecule residues, good stability, and a stable and controllable reaction process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

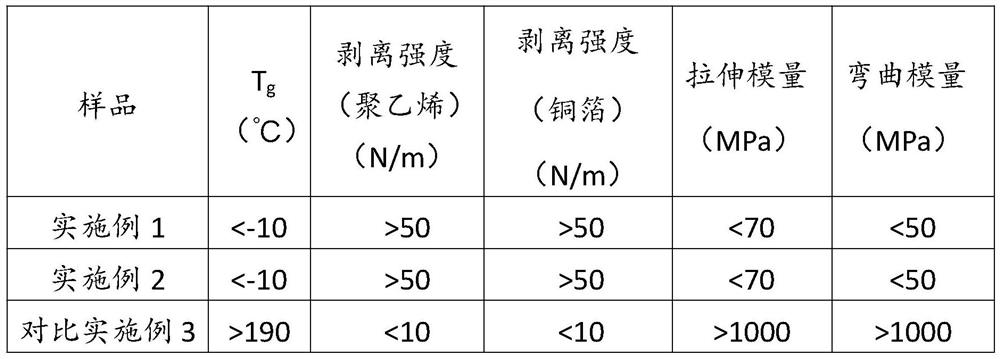

[0036] The application provides a water-soluble low-modulus acrylic resin adhesive and a preparation method thereof, the glass transition temperature of the water-soluble low-modulus acrylic resin adhesive is lower than 0°C, and its storage state is homogeneous and clear , a stable aqueous solution, the pH value of the aqueous solution is 6 to 8, the solid content is 5% to 50%, and the viscosity is 10 to 200000cp; the water-soluble low-modulus acrylic resin adhesive after drying is solid; when When the temperature is higher than 0°C, the tensile modulus and flexural modulus of the water-soluble low-modulus acrylic resin adhesive are lower than 100MPa; the preparation method of the water-soluble low-modulus acrylic resin adhesive, Including: S101, mixing water-soluble acrylate, water-soluble lower alcohol, initiator and pure water in a reaction vessel and fully stirring to obtain a clear aqueous solution, which is the reaction solution; S102, setting the temperature of the react...

Embodiment 1

[0039] 60g of pure water, 30g of isopropanol, 30g of hydroxyethyl acrylate and 0.15g of ammonium persulfate-sodium sulfite composite initiator are dropped into a three-necked bottle equipped with an electric stirring device and a reflux condenser, and the ammonium persulfate-sodium sulfite composite Initiators include: 0.1 g of ammonium persulfate and 0.05 g of sodium sulfite. Fully stir until all the materials are completely dissolved, keep stirring, raise the reaction temperature to 65°C, react for 6 hours, cool and collect.

[0040] The obtained water-soluble low modulus acrylic resin adhesive has a measured solid content of 25.1%. The state is a light yellow clear solution with a viscosity of about 75cp. The dried and cured adhesive is a brownish-yellow rosin-like solid at room temperature. It quickly absorbs moisture and becomes sticky when placed in the air. It is prone to plastic deformation under force and can quickly re-dissolve in water. When the temperature rises ...

preparation Embodiment 2

[0042] Compared with Example 1, the consumption of pure water is changed into 90g, the consumption of hydroxyethyl acrylate is changed into 60g, and the consumption of initiator is changed into 0.3g (containing ammonium persulfate 0.2g and sodium sulfite 0.1g), also added in addition 0.3g chain extender KH570, the rest are the same as in Preparation Example 1.

[0043] The obtained water-soluble low modulus acrylic resin adhesive has a measured solid content of 33.5%. The state is a light yellow clear solution with a viscosity of about 200cp. The dried and cured adhesive is a brownish-yellow translucent silicone-like solid at room temperature, which has the high elasticity of rubber, and is not sticky when placed in the air, and is prone to elastic deformation under force. It gradually swells in water and dissolves completely after standing for about 24 hours. When the temperature rises to about 55°C, the adhesive solid begins to soften gradually, but still retains high elas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com