Light salt-spray-resistant wave-absorbing coating and preparation method thereof

A wave-absorbing coating and salt-spray-resistant technology, applied in the field of coatings, can solve the problems of less data and achieve the effects of simple construction, stable product storage properties, and novel methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

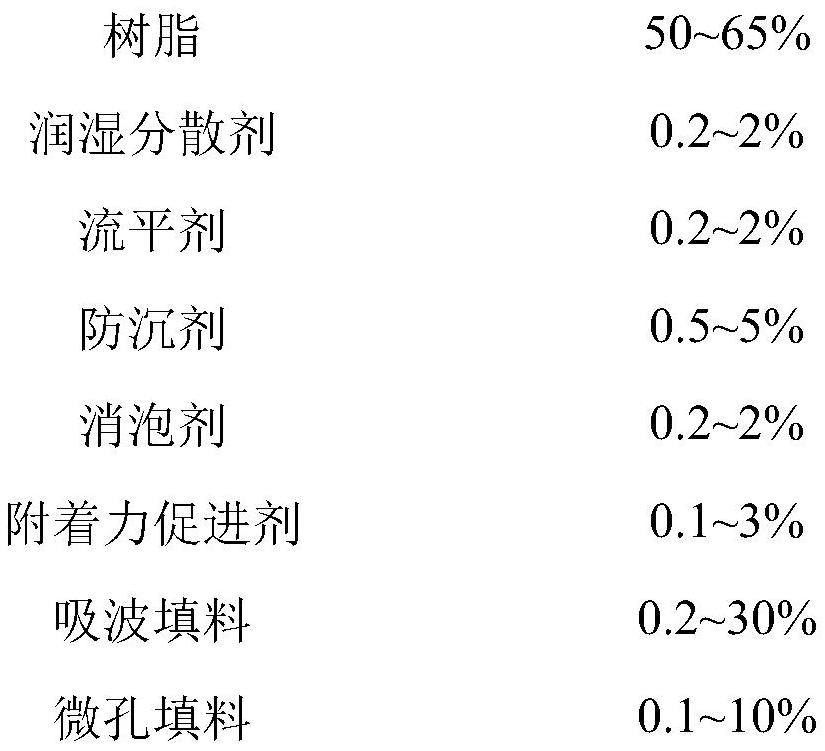

Method used

Image

Examples

Embodiment 1

[0031] (1) Add 0.5% polyether modified silicone leveling agent, 0.7% modified polysiloxane dispersant, 3% dustproof agent and other additives to the 20% acrylic modified polyurethane resin system under stirring conditions, After fully stirring at 300r / min for 30 minutes, slowly add 0.2% of the reduced graphene oxide prepared at 290°C, and continue to stir at 300r / min until the dispersion is uniform, and the radar absorbing layer coating is obtained;

[0032] (2) Add 0.5% acrylic modified silicone leveling agent, 0.3% modified polyurethane dispersant, 0.8% defoamer, 1% adhesion promoter, etc. to 40% acrylic modified polyurethane resin system under stirring conditions Auxiliary, after fully stirring at 300r / min for 30 minutes, slowly add 0.3% graphene airgel, and continue to stir at 1500r / min until it is evenly dispersed to obtain a reflective conversion layer coating;

[0033] (3) The two coatings prepared in (1) and (2) are sprayed to make a "sandwich" structure, which are: 50...

Embodiment 2

[0035] (1) Add 0.5% polyether modified silicone leveling agent, 0.7% modified polysiloxane dispersant, 3% dustproof agent and other additives to the 30% polysilane modified epoxy resin system under stirring conditions After fully stirring at 500r / min for 20 minutes, slowly add 2% of the carbon nanotubes prepared at 300°C, and continue to stir at 500r / min until the dispersion is uniform to obtain the radar absorbing layer coating;

[0036] (2) Add 0.5% acrylic modified silicone leveling agent, 0.3% modified polyurethane dispersant, 1% defoamer, 1% adhesion promoter to 35% polysilane modified epoxy resin system under stirring condition After fully stirring at 300r / min for 30 minutes, slowly add 5% hollow glass microspheres, and continue to stir at 400r / min until they are evenly dispersed to obtain a reflective conversion coating;

[0037] (3) The two coatings prepared in (1) and (2) are sprayed to make a "sandwich" structure, which are: 1000 μm bottom radar absorbing layer, 400 ...

Embodiment 3

[0039] (1) Add 0.5% polyether modified silicone leveling agent, 0.7% modified polysiloxane dispersant, 2% dustproof agent and other additives to the 30% acrylic modified silicone resin system under stirring conditions After fully stirring at 300r / min for 40 minutes, slowly add 1.5% of the reduced graphene oxide prepared at 400°C, and continue to stir at 600r / min until the dispersion is uniform to obtain the radar absorbing layer coating;

[0040] (2) Add 0.5% acrylic modified silicone leveling agent, 0.3% modified polyurethane dispersant, 1% defoamer, 1.5% adhesion promoter to 35% acrylic modified silicone resin system under stirring condition After fully stirring at 400r / min for 30 minutes, slowly add 0.3% silicon aerogel, and continue to stir at 1200r / min until it is evenly dispersed to obtain a reflective conversion coating;

[0041] (3) The two coatings prepared in (1) (2) are sprayed into a "sandwich" structure, which are: 800 μm bottom radar absorbing layer, 300 μm middle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com