Antibacterial polymer-based waterproof coating and preparation method thereof

A technology of waterproof coatings and polymers, applied in the direction of antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of reduced waterproof performance, easy growth of bacteria and deterioration, etc., to achieve optimized film-forming performance, good Bioactivity and antibacterial effect, uniform particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

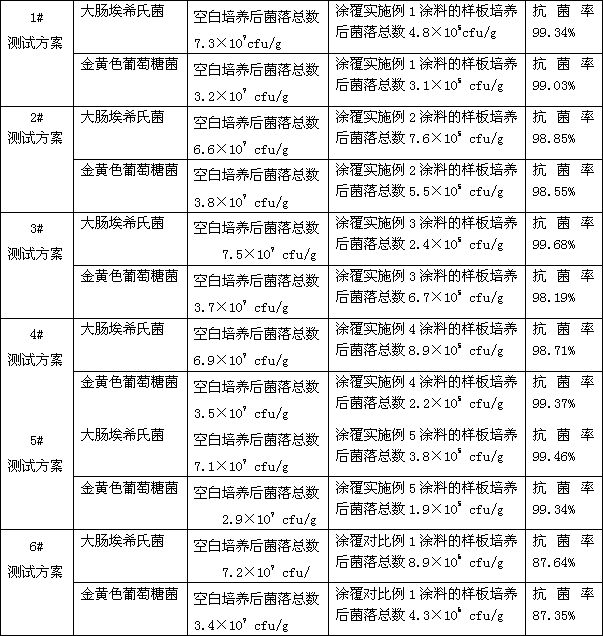

Examples

Embodiment 1

[0030] After adding 3 parts by weight of sodium hydrogen phosphate into 10 parts by weight of water to dissolve, continue to add 2 parts by weight of nano-silver and 2 parts by weight of nano-zinc oxide to stir and disperse, and then slowly add 5 parts by weight of chitosan acetic acid solution with a mass concentration of 10%. , after mixing evenly, add 5 parts by weight of saturated calcium nitrate solution dropwise at a constant speed, adjust the pH to 11 with ammonia water after the dropwise addition, continue stirring for 1 hour, let stand at room temperature for 10 hours, filter and then vacuum dry at 100 ° C, pulverize Pass through a 100-mesh sieve to obtain the chitosan-calcium hydroxyphosphate composite material loaded with nano-silver and nano-zinc oxide antibacterial agent. 1 part by weight of antibacterial agent and 30 parts by weight of acrylic acid emulsion with a solid content of 57%, 30 parts by weight of acrylic acid emulsion with a solid content of 55%, 0.2 pa...

Embodiment 2

[0032] After adding 4 parts by weight of sodium hydrogen phosphate to 12 parts by weight of water to dissolve, continue to add 3 parts by weight of nano-silver and 3 parts by weight of nano-zinc oxide to stir and disperse, and then slowly add 6 parts by weight of chitosan acetic acid solution with a mass concentration of 10%. , after mixing evenly, add 6 parts by weight of saturated calcium nitrate solution dropwise at a constant speed, adjust the pH to 10 with ammonia water after the dropwise addition, continue stirring for 2 hours, let stand at room temperature for 11 hours, filter and then vacuum dry at 100 ° C, pulverize Pass through a 100-mesh sieve to obtain the chitosan-calcium hydroxyphosphate composite material loaded with nano-silver and nano-zinc oxide antibacterial agent. 2 parts by weight of antibacterial agent and 33 parts by weight of acrylic acid emulsion with a solid content of 57%, 32 parts by weight of acrylic acid emulsion with a solid content of 55%, 0.3 pa...

Embodiment 3

[0034] After adding 6 parts by weight of sodium hydrogen phosphate into 15 parts by weight of water to dissolve, continue to add 4 parts by weight of nano-silver and 4 parts by weight of nano-zinc oxide to stir and disperse, and then slowly add 8 parts by weight of chitosan acetic acid solution with a mass concentration of 10%. , after mixing evenly, add 8 parts by weight of saturated calcium nitrate solution dropwise at a constant speed, adjust the pH to 10 with ammonia water after the dropwise addition, continue stirring for 1 hour, let stand at room temperature for 10 hours, filter and then vacuum dry at 100 ° C, pulverize Pass through a 100-mesh sieve to obtain the chitosan-calcium hydroxyphosphate composite material loaded with nano-silver and nano-zinc oxide antibacterial agent. 3 parts by weight of antibacterial agent and 36 parts by weight of propylene styrene emulsion with a solid content of 57%, 35 parts by weight of acrylic acid emulsion with a solid content of 55%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com