Diamine monomer containing spirofluorene functional group, preparation method thereof and polyimide with low dielectric constant

A technology of functional groups and diamine monomers, which is applied in the field of polyimide with low dielectric constant, can solve the problems of high dielectric constant and low dielectric constant of polyimide, improve dimensional stability, The effect of lowering the dielectric constant and compensating for the lowering of the glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

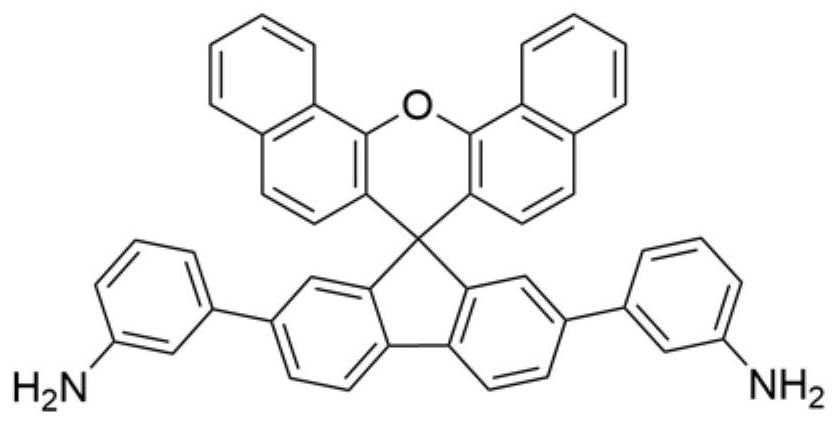

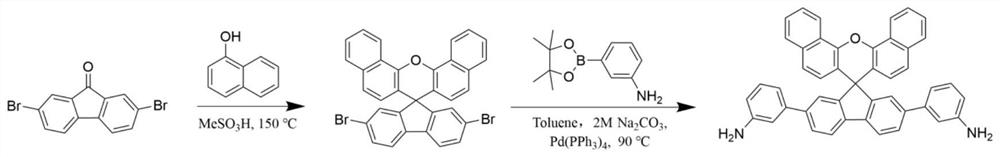

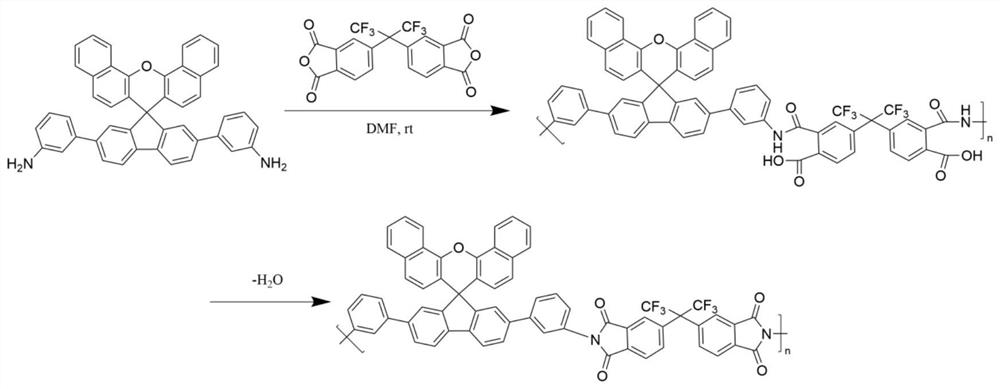

[0043] The structural formula of the diamine monomer (1,3-SFDA) containing the spirofluorene functional group in this embodiment is as follows figure 1 Shown, concrete synthetic steps are as follows (as figure 2 ):

[0044] (1) Under a nitrogen atmosphere, mix 2,7-dibromofluorenone (8g, 23.68mmol), 1-naphthol (20.46g, 142.04mmol) and methanesulfonic acid (6.2mL, 94.688mmol) at 150°C Heated and stirred for 24h. After the reaction was completed, the reaction mixture was poured into water and extracted with dichloromethane. The organic layer was dried with anhydrous magnesium sulfate, filtered, and separated by column chromatography after decompression distillation to remove the solvent. The eluent was a mixed solvent of sherwood oil and dichloromethane to obtain a yellow solid with a yield of about 60% (8.4 g).

[0045] (2) Under a nitrogen atmosphere, tetrakis(triphenylphosphine)palladium (169mg, 0.44mmol) was added to the yellow solid (4g, 6.8mmol) obtained in step (1), 3-(...

Embodiment 2

[0049] The structural formula of the diamine monomer (1,4-SFDA) containing the spirofluorene functional group in this embodiment is as follows Figure 4 Shown, concrete synthetic steps are as follows (as Figure 5 ):

[0050] (1) Under a nitrogen atmosphere, tetrakis(triphenylphosphine)palladium (169mg, 0.44mmol) was added to the yellow solid (4g, 6.8mmol) obtained in step (1) of Example 1, 4-( 4,4,5,5-Tetramethyl-1,3,2-dioxaborolan-2-yl)aniline (3.4g, 14.64mmol), aqueous sodium carbonate (2M, 15mL, 30mmol), toluene ( 250mL) and ethanol (15mL) in a mixture. The reaction was heated to 90°C and stirred overnight. After cooling to room temperature, the reaction mixture was introduced into water and extracted with dichloromethane. The organic layer was dried with anhydrous magnesium sulfate, filtered, separated by column chromatography after decompression distillation to remove the solvent, and the eluent was a mixed solvent of sherwood oil and dichloromethane to obtain the ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com