Ultrasonic composite perforating machine

A technology of ultrasonic and punching machine, applied in the direction of lamination device, lamination auxiliary operation, lamination, etc., can solve the problems that the composite effect cannot meet the requirements, the ultrasonic laminating machine cannot be applied, and the discrete holes are punched, and the composite effect is strong. , Reduce process steps, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

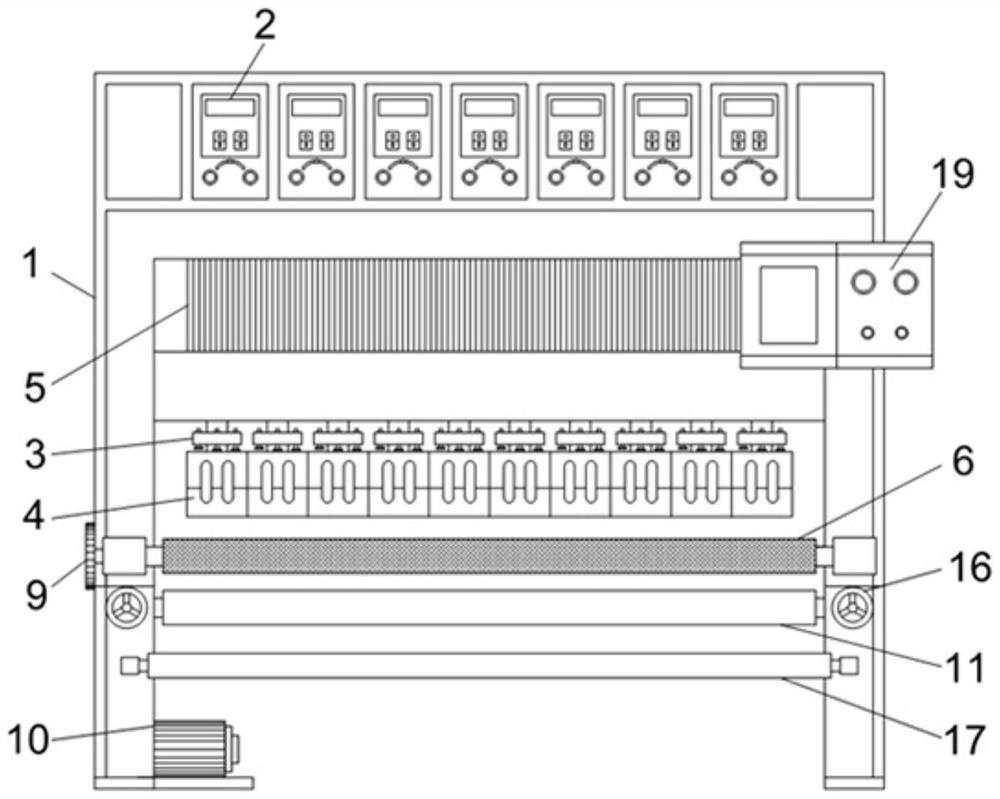

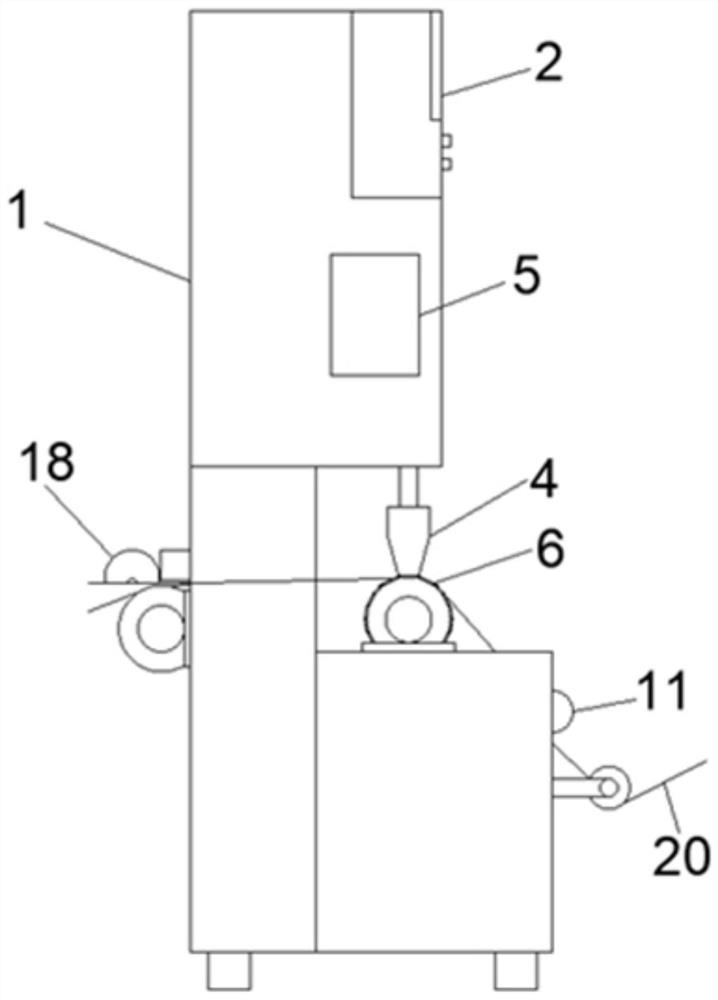

[0022] Such as figure 1 , 2 , 3 and 4, an ultrasonic composite punching machine, wherein:

[0023]Including frame 1, several ultrasonic generators 2 are arranged on the top of the frame, the output end of the ultrasonic generator is connected to the hot pressing block 4 through the adjustment flange 3 and the sound wave is transmitted by the hot pressing block, and the output end of the ultrasonic generator is fixedly connected with Dustproof cover 5, the bottom of frame is provided with perforated paper roll 6, and the outer wall of perforated paper roll is provided with the salient point 7 that is used to perforate composite filter paper 20, and the inner side of perforated paper roll is fixedly connected with for Its electric heating network 8 for heating is also fixedly connected with a sprocket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com