Finish-grinding treatment device and method for preventing hollow shaft center deformation

A technology of processing device and processing method, which is applied in the direction of grinding drive device, grinding machine, grinding workpiece support, etc., and can solve the problems such as poor cylindricity of the outer circle of the hollow shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is further described in detail through specific implementation methods:

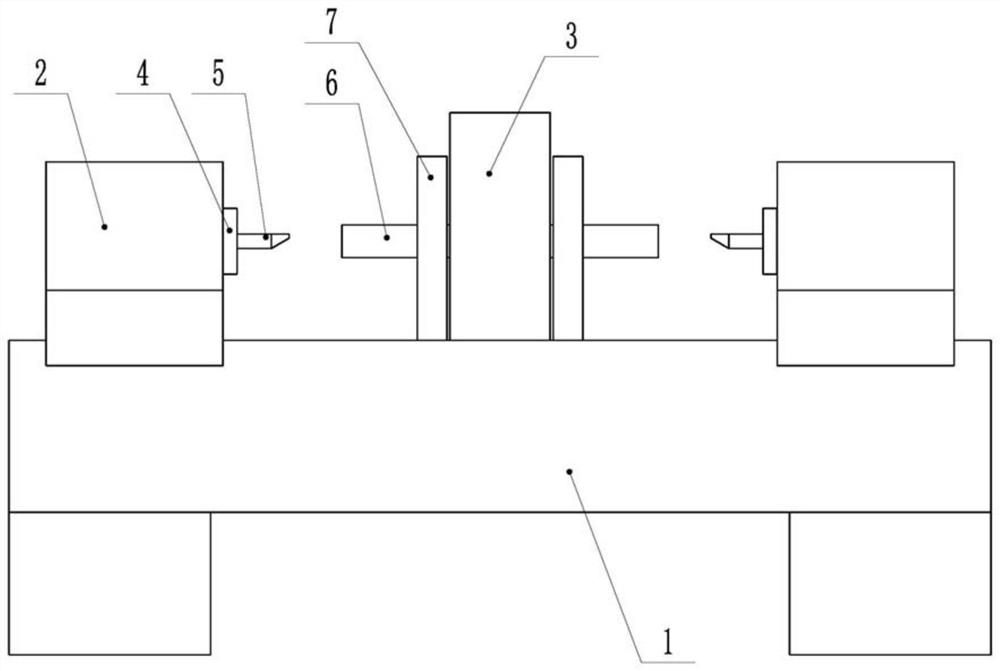

[0029] The reference signs in the accompanying drawings of the specification include: workbench 1, power box 2, clamping box 3, tool tooling 4, tool 5, hollow shaft 6, positioning unit 7, bottom plate 8, mounting plate 9, limit ring 10, Chute 11, pressing block 12, pressing wheel 13, rotating block 14, fixed post 15, moving block 16, connecting block 17, mounting block 18, leading screw 19, rotating rod 20, mounting hole 21, support plate 22.

[0030] The embodiment is basically as attached figure 1 Shown: A fine grinding treatment method to prevent the deformation of the center of the hollow shaft, including the following steps:

[0031] Step (1), heat treatment processing: performing heat treatment on the hollow shaft formed through rough machining;

[0032] Step (2), correcting the center hole, installing the hollow shaft after the heat treatment in step (2) on the fine grinding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com