Double hydraulic internal mixer

An internal mixer and double hydraulic technology, applied in the field of internal mixer, can solve the problems of product quality decline, poor mixing effect, unstable pressure, etc., and achieve the effect of increasing service life, good mixing effect and uniform pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

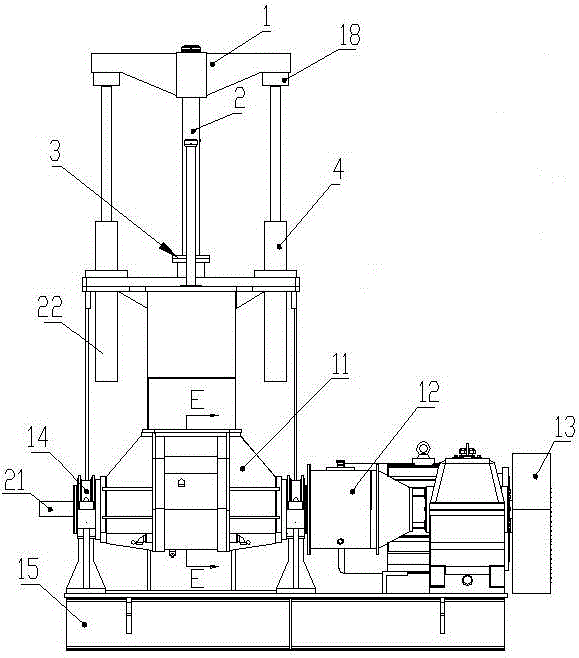

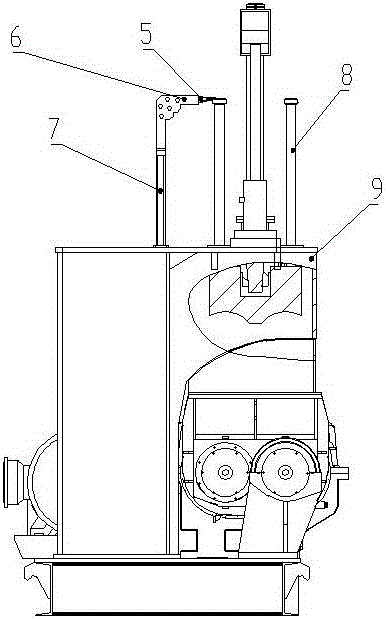

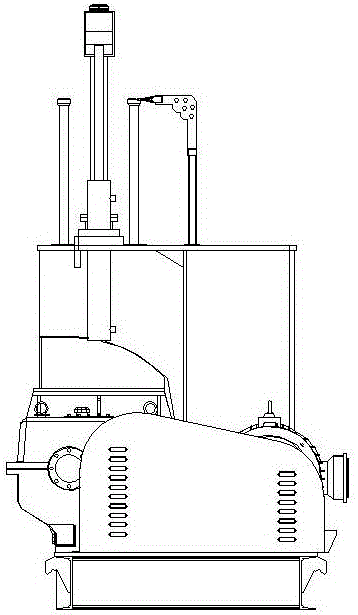

[0022] Double hydraulic internal mixer structure of the present invention is as Figure 1-6 As shown, the frame 9 is installed on the frame base 15, the first hydraulic cylinder 4 and the second hydraulic cylinder 22 piston rods are connected to the upper bolt 1 by bolts 18, and the first hydraulic cylinder 4 and the second hydraulic cylinder 22 are installed on the Frame 9, the machine is supplied with oil to the hydraulic cylinder by the hydraulic station, thereby realizing the top bolt on the machine tool to move up and down. The upper top bolt 1 is a triangular structure, such as Figure 9 As shown, the piston rod guiding device 3 is installed in the middle of the frame 9, the upper part of the piston rod 2 is connected to the top bolt 1, and the lower part of the piston rod 2 is connected to the piston rod guiding device 3; On the seat 14, the rotor is connected to the mixing mechanism 11, and the mixing mechanism is connected to the transmission mechanism 13 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com