Self-shielded flux-cored wire formula and process

A technology of flux-cored welding wire and self-protection, which is applied in the direction of welding medium, manufacturing tools, welding equipment, etc., can solve the problems of poor overall structural toughness and drawing performance, easy oxidation of the internal flux core, and lack of isolation protection, etc. Promote and use, improve the antioxidant capacity, improve the effect of drug core compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

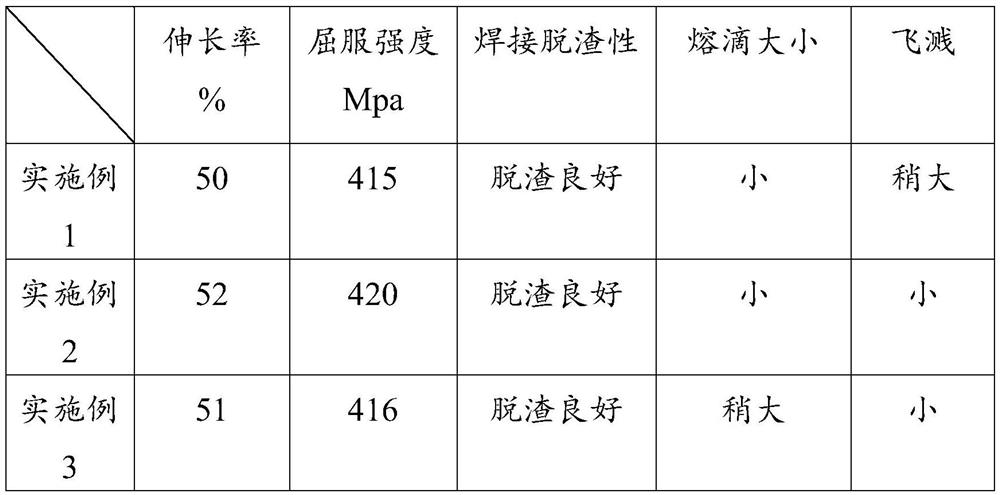

Embodiment 1

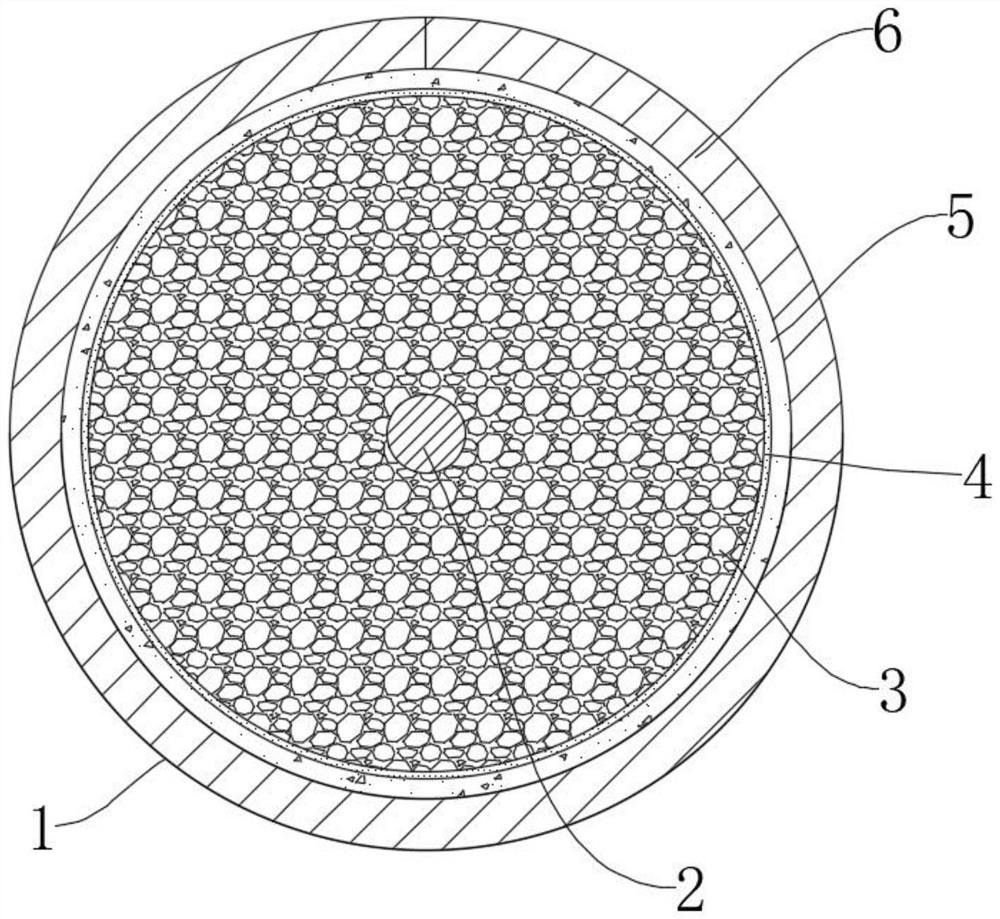

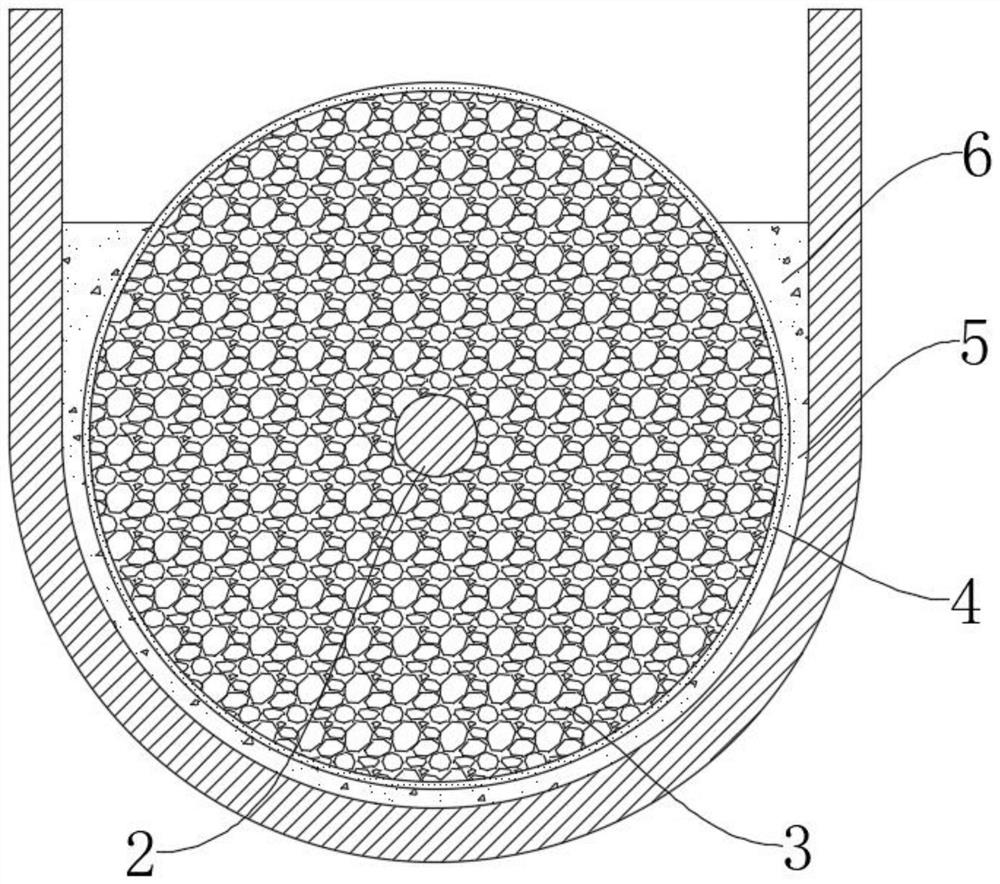

[0038] The present invention provides such Figure 1-2 A formula of self-shielding flux-cored welding wire shown, including a flux-cored welding wire body 1, said flux-cored welding wire body 1 is made of an aluminum strip 2, a flux core layer 3, a wrapping layer 4, an isolation layer 5 and an outer coiled steel layer 6 The aluminum strip 2, the drug core layer 3, the wrapping layer 4, the isolation layer 5 and the outer steel coil layer 6 are coaxially distributed, and the aluminum strip 2, the drug core layer 3, the wrapping layer 4, the isolation layer 5 and the outer coil The steel layer 6 is wrapped and arranged sequentially from the inside to the outside;

[0039] The main materials used in the drug core layer 3 include by weight: 10 parts of rutile powder, 8 parts of anorthite powder, 5 parts of dolomite powder, 6 parts of aluminum-magnesium alloy powder, 3 parts of fluoride, 3 parts of molybdenum powder, 1 part of zirconium powder, 4 parts of silicon nitride, 5 parts ...

Embodiment 2

[0059] The present invention provides such Figure 1-2 A formula of self-shielding flux-cored welding wire shown, including a flux-cored welding wire body 1, said flux-cored welding wire body 1 is made of an aluminum strip 2, a flux core layer 3, a wrapping layer 4, an isolation layer 5 and an outer coiled steel layer 6 The aluminum strip 2, the drug core layer 3, the wrapping layer 4, the isolation layer 5 and the outer steel coil layer 6 are coaxially distributed, and the aluminum strip 2, the drug core layer 3, the wrapping layer 4, the isolation layer 5 and the outer coil The steel layer 6 is wrapped and arranged sequentially from the inside to the outside;

[0060] The main materials used in the drug core layer 3 include by weight: 15 parts of rutile powder, 12 parts of anorthite powder, 6 parts of dolomite powder, 8 parts of aluminum-magnesium alloy powder, 3.5 parts of fluoride, 3.5 parts of molybdenum powder, 1.5 parts of zirconium powder, 5 parts of silicon nitride, ...

Embodiment 3

[0080] The present invention provides such Figure 1-2 A formula of self-shielding flux-cored welding wire shown, including a flux-cored welding wire body 1, said flux-cored welding wire body 1 is made of an aluminum strip 2, a flux core layer 3, a wrapping layer 4, an isolation layer 5 and an outer coiled steel layer 6 The aluminum strip 2, the drug core layer 3, the wrapping layer 4, the isolation layer 5 and the outer steel coil layer 6 are coaxially distributed, and the aluminum strip 2, the drug core layer 3, the wrapping layer 4, the isolation layer 5 and the outer coil The steel layer 6 is wrapped and arranged sequentially from the inside to the outside;

[0081] The main materials used in the drug core layer 3 include by weight: 20 parts of rutile powder, 15 parts of anorthite powder, 7 parts of dolomite powder, 10 parts of aluminum-magnesium alloy powder, 4 parts of fluoride, 4 parts of molybdenum powder, 2 parts of zirconium powder, 7 parts of silicon nitride, 8 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com