Making method for improving quality of whole wheat bread

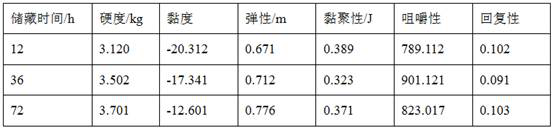

A production method and technology for whole-wheat bread, which are applied in the directions of dough preparation, dough processing, pre-baked dough processing, etc., can solve the problems of poor storage stability, low dietary fiber content, and high crude fiber content of whole-wheat bread, and improve the storage efficiency. Stability, bread elasticity enhancement, cross-linking promotion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

[0019] 1. Preparation of yeast-based carbon dots: Dissolve 3-5kg of yeast powder in 100 kg of deionized water, transfer to a polytetrafluoroethylene reactor, heat at 200°C for 24 hours, cool naturally, and use a filter membrane with a pore size of 0.22μm Filtration to obtain yeast-based carbon dots.

[0020] 2. Preparation of chlorine-doped carbon dots: Mix 1 mole of choline chloride with 1 mole of glycine, stir and dissolve at 80°C to form a uniform liquid, cool to room temperature, add 0.5-1kg of citric acid and 100-150 kg of deionized water, and transferred to a polytetrafluoroethylene reactor, heated at 180° C. for 8-10 hours, cooled naturally, and filtered with a filter membrane with a pore size of 0.22 μm to obtain chlorine-doped carbon dots.

[0021] 3. Prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com