Fire-resistant-1100 DEG C mineral low-voltage cable and preparation method thereof

A low-voltage cable and mineral technology, applied in the field of mineral cables and their preparation, can solve the problems of easy moisture absorption of MgOH2, melting of copper sheath, and easy failure, and achieve long preparation time, reduce smoke, and delay burning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

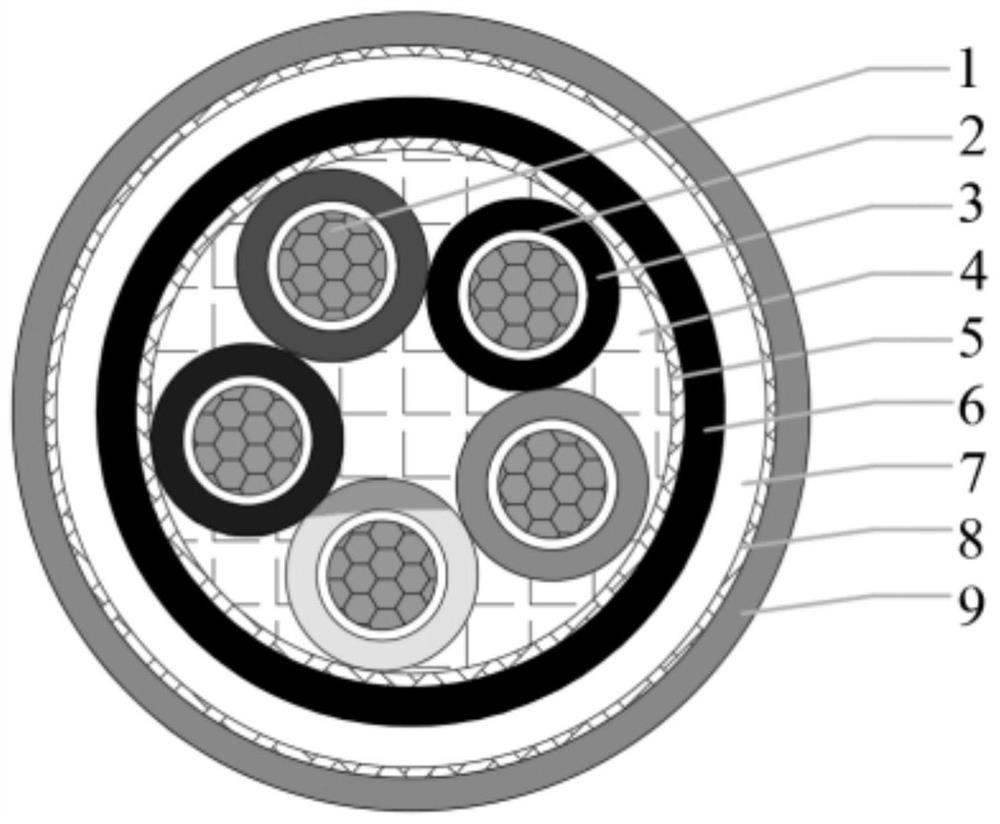

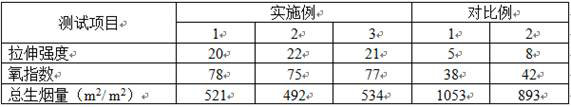

[0044] Embodiments 1-3: A fire-resistant 1100°C mineral low-voltage cable, including multiple conductors 1 distributed in a ring shape, and each conductor 1 is provided with a fire-resistant wrapping tape 2 and an insulating layer 3 in turn. A first wrapping tape 5 is provided on the outside of the multiple conductors 1, and an alkali-free glass fiber filling rope 4 is filled between the first wrapping tape 5 and the plurality of conductors 1, and spacers are arranged on the outside of the first wrapping tape 5 in turn Oxygen layer 6, refractory layer 7 and second tape 8, the first tape 5 and the second tape 8 are alkali-free glass fiber tapes, and an outer sheath 9 is provided on the outside of the second tape 8;

[0045] The preparation method of the oxygen barrier layer comprises the following steps:

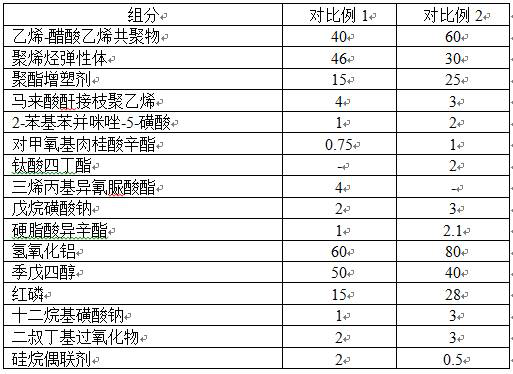

[0046] S1. Put 40~80 parts of ethylene-vinyl acetate copolymer resin, 30~50 parts of polyolefin elastomer, 15~30 parts of polyester plasticizer and 2~4 parts of maleic anhydr...

Embodiment 2

[0054] The content of vinyl acetate in the ethylene-vinyl acetate copolymer resin in Example 2 is 48%, and the addition ratio of 2-phenylbenzimidazole-5-sulfonic acid and octyl p-methoxycinnamate is 2:1, The ratio of tetrabutyl titanate to triallyl isocyanurate is 1:1, the ratio of aluminum hydroxide, pentaerythritol, and red phosphorus is 4:2:1, and the silane coupling agent is methyltrimethoxysilane ;

Embodiment 3

[0055] The content of vinyl acetate in the ethylene-vinyl acetate copolymer resin in Example 3 is 50%, and the addition ratio of 2-phenylbenzimidazole-5-sulfonic acid to octyl p-methoxycinnamate is 2:1. The addition ratio of tetrabutyl ester to triallyl isocyanurate is 2:1, the addition ratio of aluminum hydroxide, pentaerythritol, and red phosphorus is 4:2:1, and the silane coupling agent is phenyltrimethoxysilane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com