Waste heat comprehensive energy recovery device for diesel engine

An energy recovery device and diesel engine technology, which is applied in exhaust devices, noise reduction devices, mechanical equipment, etc., can solve the problems of power generation efficiency discount, complex power transformation system, high investment, etc., to increase external output power, reduce fuel consumption rate, The effect of lowering the exhaust gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

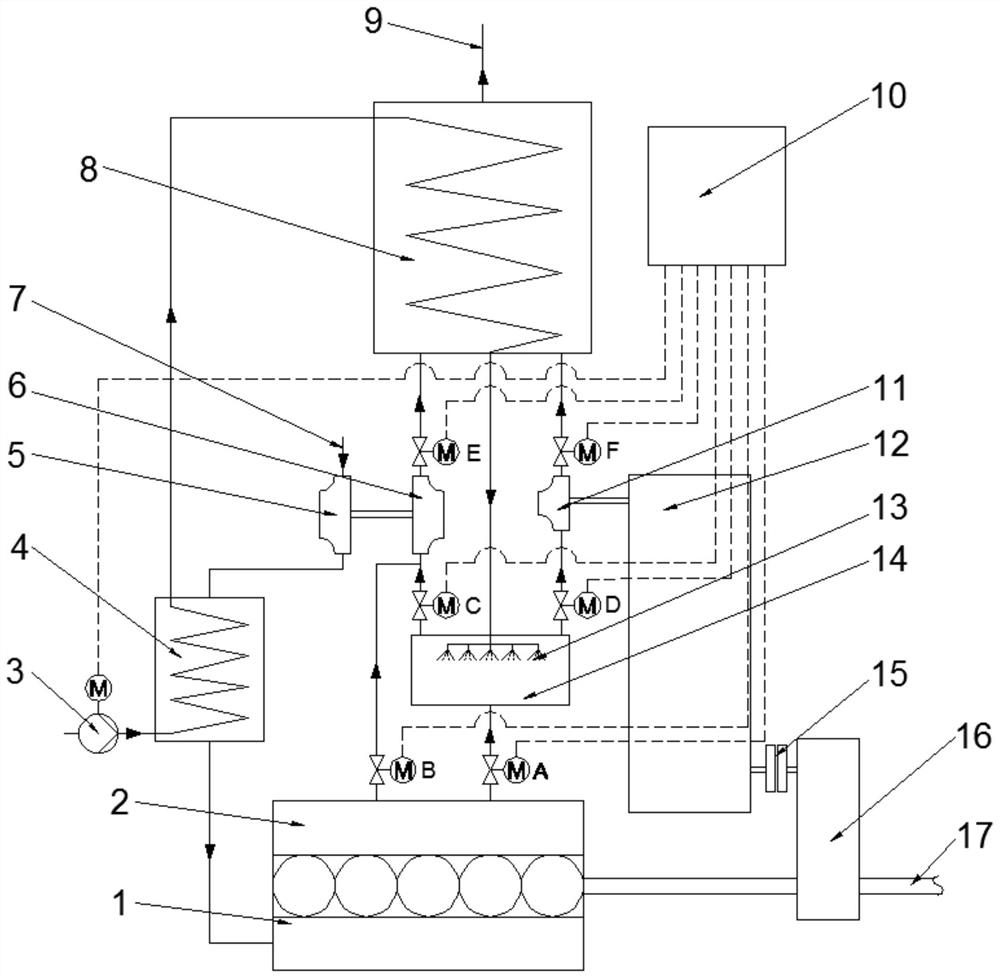

[0033] Embodiment 1: The waste heat recovery system is in normal working condition.

[0034] When the waste heat recovery system is working normally, control valve A, control valve C, control valve D, control valve E and control valve F are opened, control valve B is closed, and the flue gas from the main exhaust pipe 2 of the diesel engine enters the evaporator through control valve A In 14, it is mixed with the high-temperature water or steam-water mixture that comes from the water booster pump 3 and is heated by the pressurized air heat exchanger 4 and the flue gas heat exchanger 8, and enters the evaporator 14 through the nozzle 13, and in the evaporator 14 is mixed with high-temperature flue gas and quickly evaporated into superheated steam to form a mixture of superheated steam and flue gas; part of the gaseous mixture enters the exhaust gas turbocharger turbine 6 under the control of the control valve C to drive the coaxial exhaust gas turbine The supercharger compresso...

Embodiment approach 2

[0037] Embodiment 2: Diesel engine low load operating condition.

[0038] Under the condition of low load, under the control of the control device 10, the control valves A, C, and E are opened, the control valves B, D, and F are closed, the clutch 15 is disengaged, and the power turbine 11 is not engaged. Work. The high-temperature steam or steam-water mixture formed after the water flows through the water booster pump 3, the booster air heat exchanger 4 and the flue gas heat exchanger 8 is mixed, enters the evaporator 14 through the nozzle 13, and is mixed with the smoke in the evaporator 14. The gas is mixed to form a mixture of superheated steam and smoke, which only drives the exhaust turbocharger of the diesel engine to increase the pressure of the boosted air of the diesel engine, and improves the dynamic power response and working efficiency of the diesel engine under partial load conditions. The flue gas discharged from the exhaust gas turbocharger turbine 6 enters th...

Embodiment approach 3

[0040] Implementation mode 3: emergency working conditions.

[0041] When the waste heat recovery system fails to work, under the control of the control device 10, the control valve A, control valve C, control valve D, and control valve F are closed, and the control valve B and control valve E are opened. The clutch 15 is disengaged, and the system Return to the initial setting of the diesel engine, the exhaust gas in the exhaust manifold 2 of the diesel engine directly enters the exhaust turbocharger turbine 6, and drives the exhaust turbocharger to work to ensure the normal operation of the diesel engine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com