Ceramic composite powder for thermal spraying and preparation method of ceramic composite powder

A ceramic composite and thermal spraying technology, applied in coating, fusion spraying, metal material coating process, etc., can solve problems such as unsatisfactory tribological properties, achieve excellent dispersion, reduce oxidation and burning loss, and improve durability abrasive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

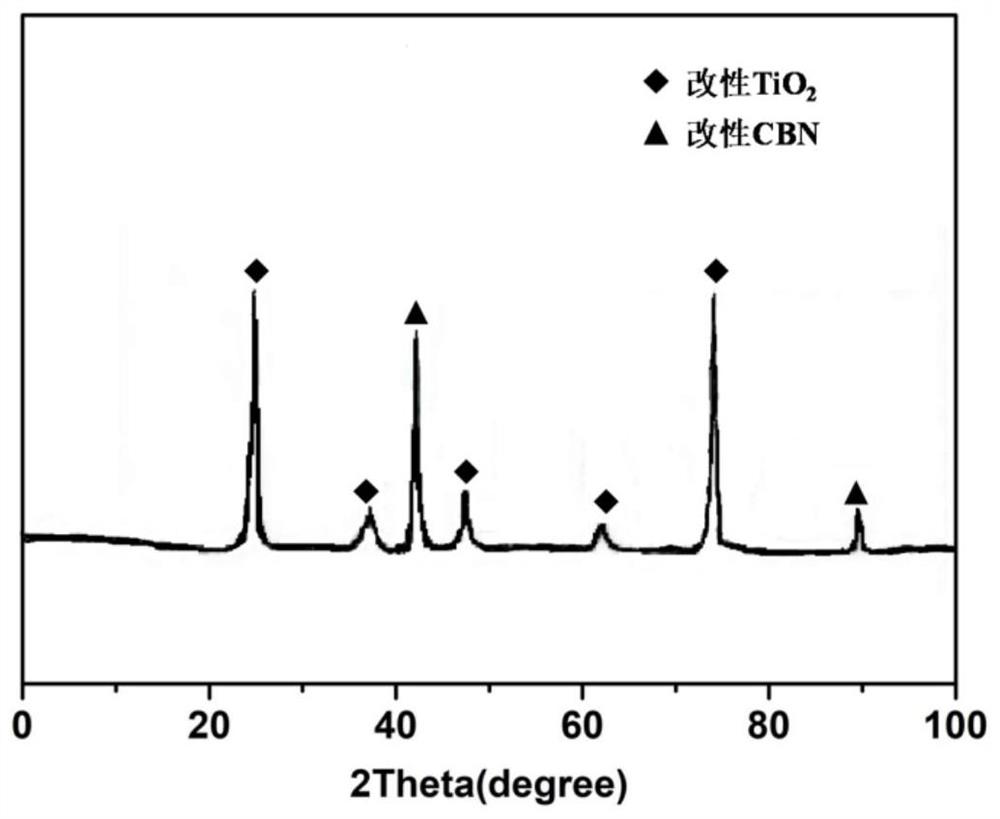

[0039] (1) Preparation of modified CBN

[0040] The CBN powder was weighed, washed with absolute ethanol, centrifuged and dried, placed in a muffle furnace, heated to 750° C. in an air atmosphere, and kept for 0.5-1 h to obtain a surface-modified CBN powder.

[0041] (2) Modified TiO 2 preparation

[0042] Mix 1 mL of tetrabutyl titanate and 8 mL of anhydrous ethanol evenly under magnetic stirring, slowly add the mixed liquid dropwise to 10 mL of deionized water, and move the resulting white liquid to a In a 500mL three-necked flask, and placed in a constant temperature water bath, mechanically stirred at 70°C until viscous, and reacted with 20mL of nitric acid solution in a water bath at 65 to 70°C for 3 to 4 hours. After the reaction was completed, the obtained Sol-like TiO 2 ; Distilled under reduced pressure at 60 °C to distill the TiO 2 The wet solid was evaporated to a viscous state, and then rotary evaporated with 30 mL of anhydrous ethanol for 2 to 4 times. After e...

Embodiment 1

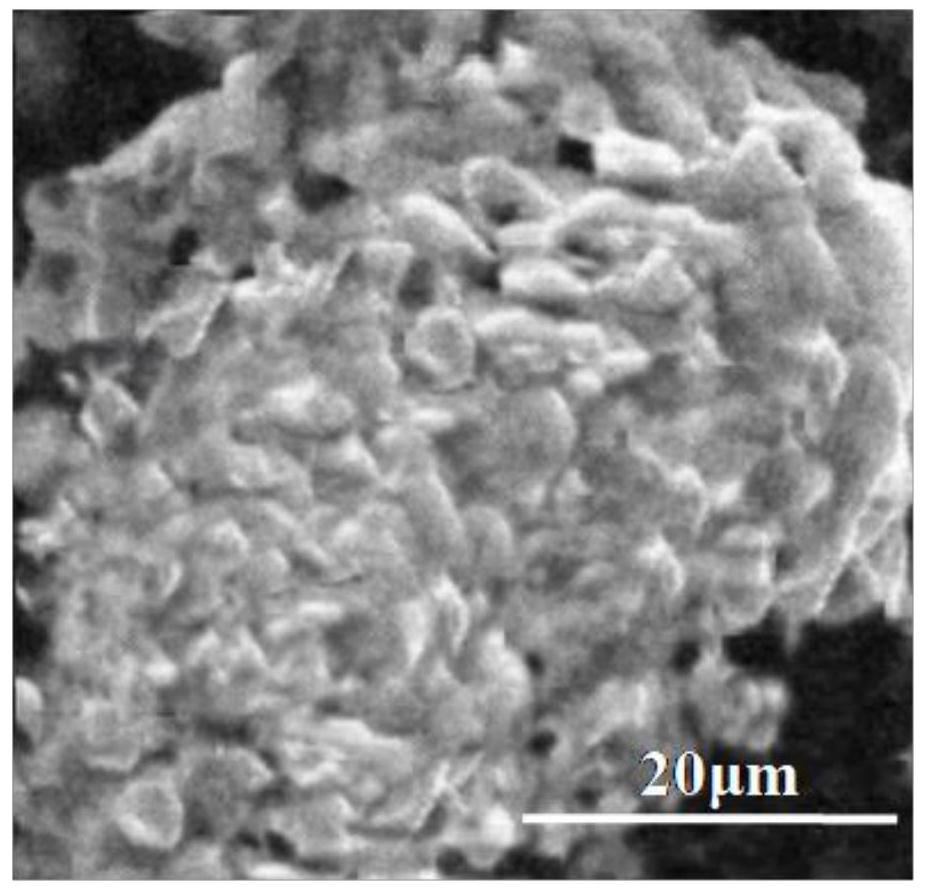

[0045] The preparation method of ceramic composite powder for thermal spraying comprises the following steps:

[0046] Dissolve aluminum nitrate nonahydrate in deionized water, prepare an aluminum salt solution with a concentration of 0.15 mol / L, and stir magnetically until the aluminum salt is completely dissolved; add yttrium oxide to deionized water and mix, ultrasonically disperse the yttrium oxide in the water, and disperse the yttrium oxide in the water. Add concentrated nitric acid to the good yttrium oxide suspension, heat and stir in a 50 ℃ water bath until the yttrium oxide is completely dissolved, prepare a yttrium salt solution with a concentration of 0.055mol / L, and then add ammonia water dropwise under the action of magnetic stirring, Until a small amount of white flocculent precipitate appeared in the solution, and a small amount of concentrated nitric acid was added to the white precipitate and disappeared immediately. The prepared yttrium salt solution and the...

Embodiment 2

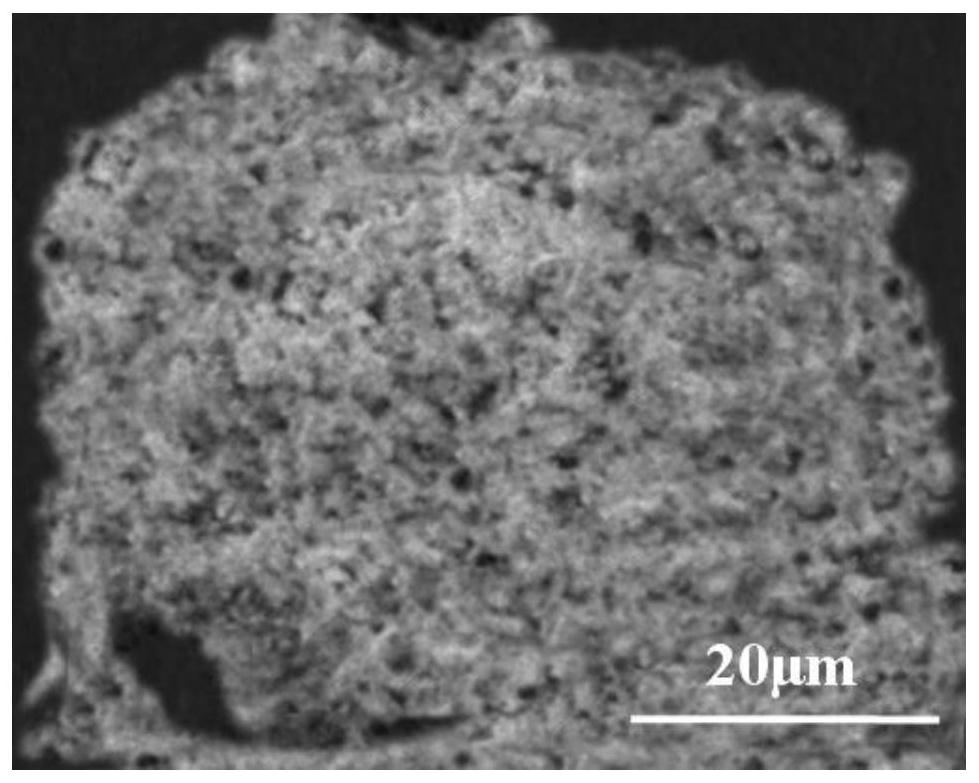

[0049] The preparation method of ceramic composite powder for thermal spraying comprises the following steps:

[0050] Dissolve aluminum nitrate nonahydrate in deionized water, prepare an aluminum salt solution with a concentration of 0.2 mol / L, stir magnetically until the aluminum salt is completely dissolved; add yttrium oxide into deionized water and mix, ultrasonically disperse the yttrium oxide in the water, and disperse the yttrium oxide in the water. Add concentrated nitric acid to the good yttrium oxide suspension, heat and stir in a 45°C water bath until the yttrium oxide is completely dissolved, prepare a yttrium salt solution with a concentration of 0.1mol / L, and then add ammonia water dropwise under the action of magnetic stirring, Until a small amount of white flocculent precipitate appeared in the solution, and a small amount of concentrated nitric acid was added to the white precipitate and disappeared immediately. The prepared yttrium salt solution and the alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com