Light-emitting device using quantum dot color conversion and its manufacturing method

A technology of light-emitting devices and quantum dot materials, applied in semiconductor devices, electrical components, circuits, etc., to achieve the effects of reducing oxidation, low water vapor permeability, and reducing the intensity of blue light per unit area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

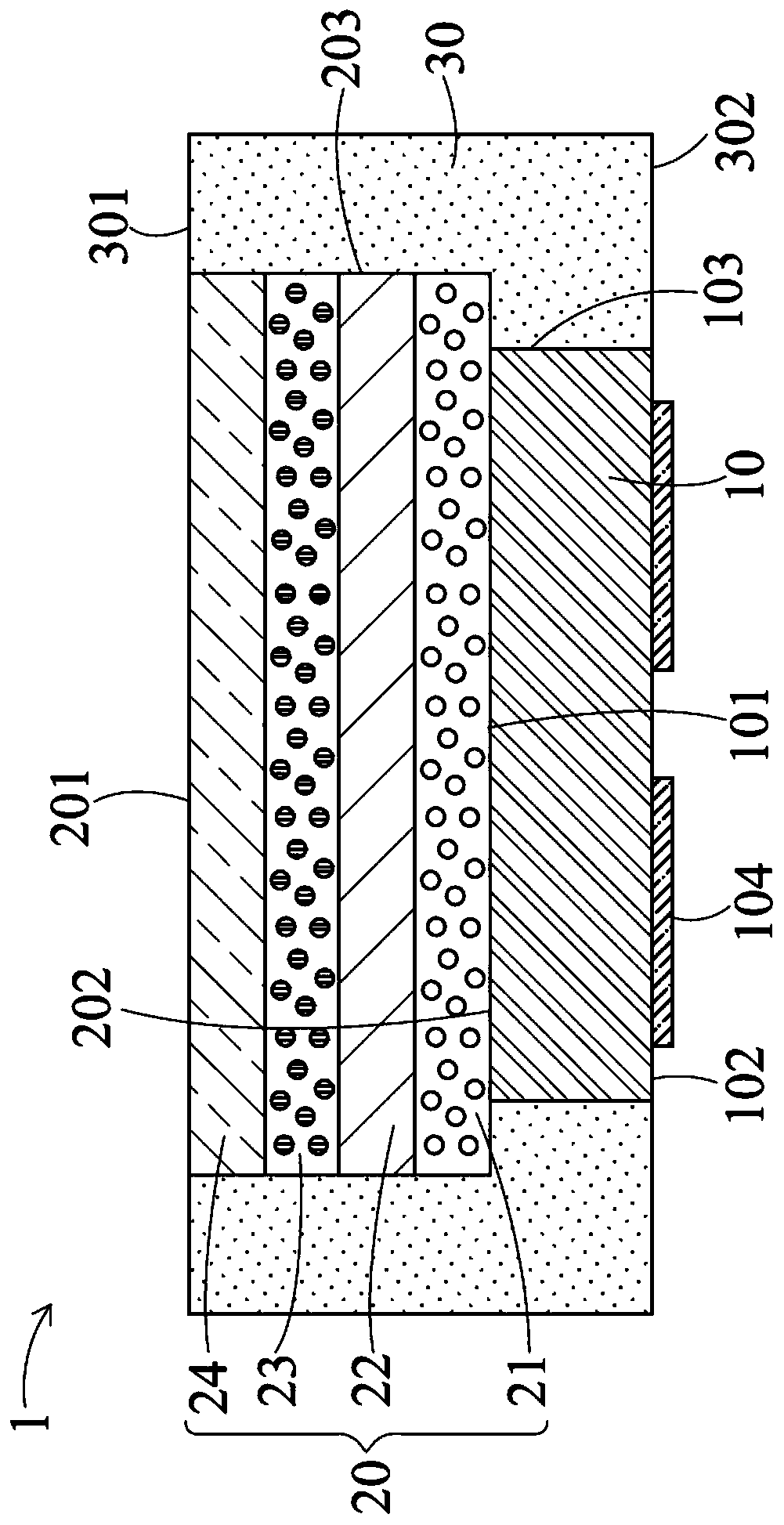

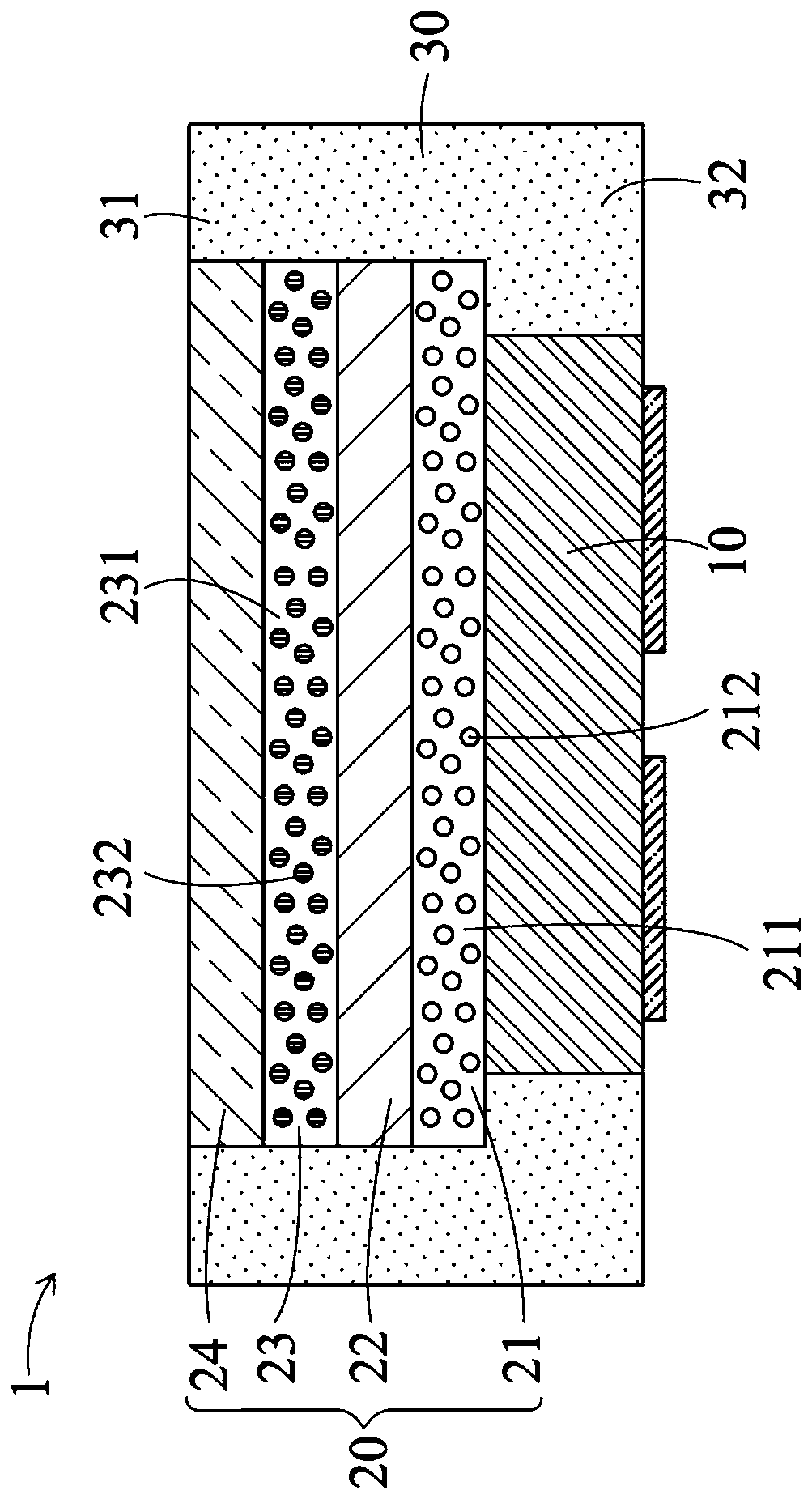

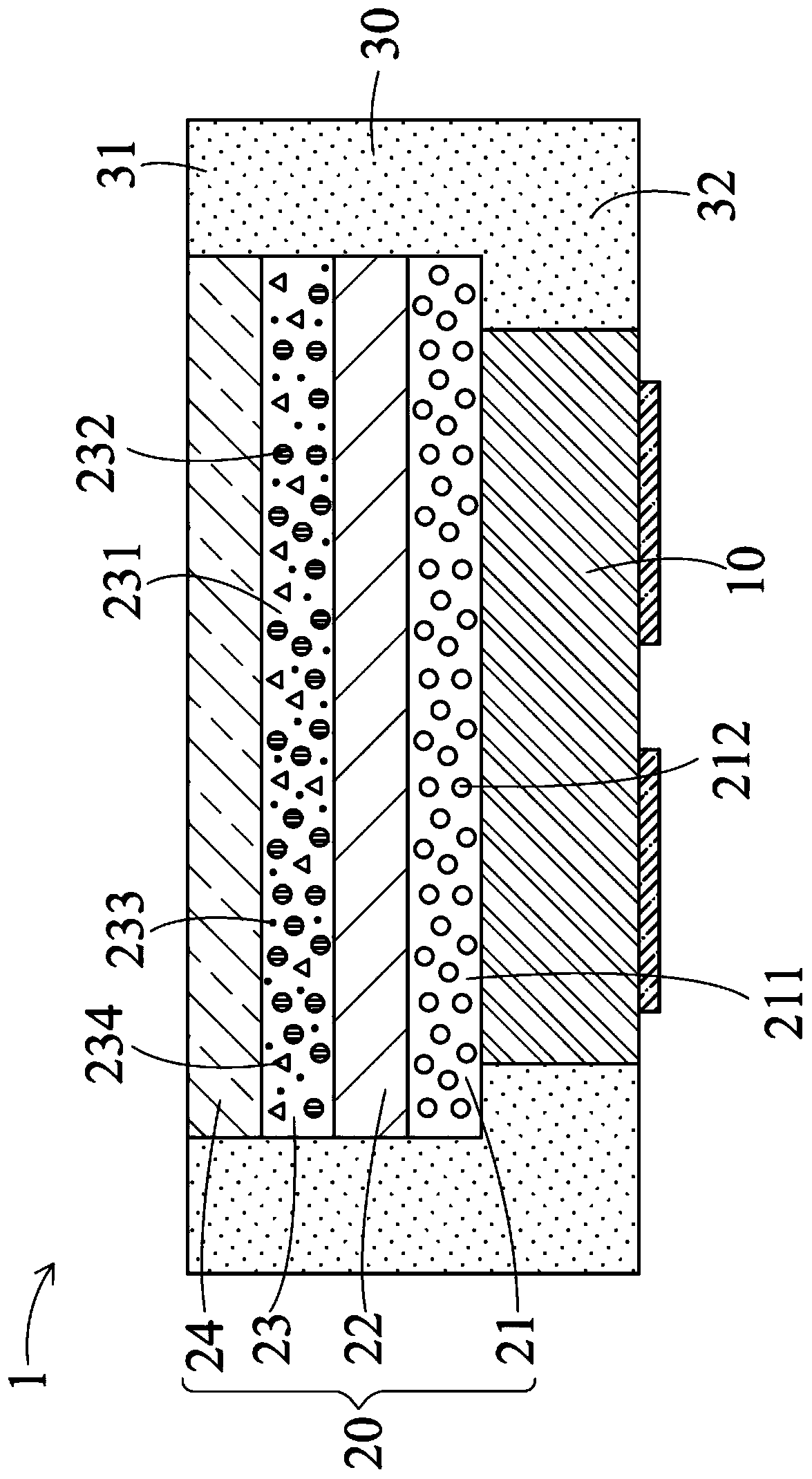

[0067] see Figure 1A and Figure 1B , which is a schematic diagram of the light emitting device 1 according to the first preferred embodiment of the present invention. The light emitting device 1 may include a flip-chip LED chip 10 , a photoluminescent structure 20 and a moisture barrier reflective structure 30 , and the technical content of each component will be described in sequence as follows.

[0068] The flip-chip LED chip (hereinafter referred to as the LED chip) 10 is used to provide a first light (or main light), which can be a blue light, a deep blue light, a purple light or a ultraviolet light and other higher energy level light; Taking a blue LED chip as an example, the first light provided by the LED chip 10 is blue light. The chip 10 may include an upper surface 101, a lower surface 102, a vertical surface 103 and an electrode group 104. The upper surface 101 and the lower surface 102 are oppositely arranged, and the vertical surface 103 is formed between the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com