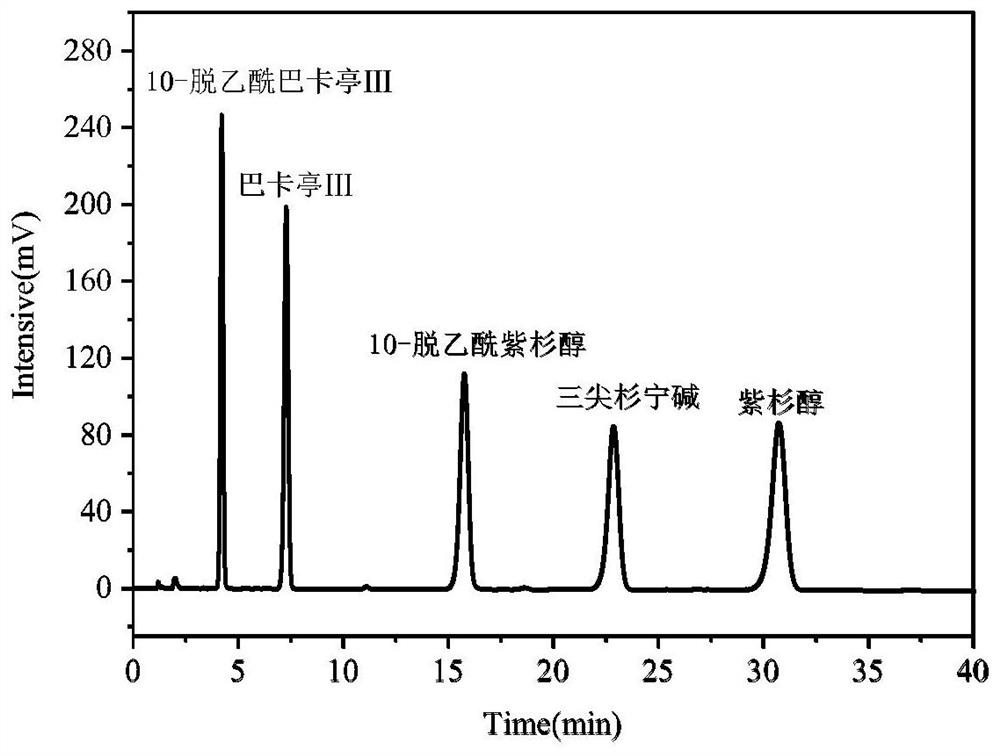

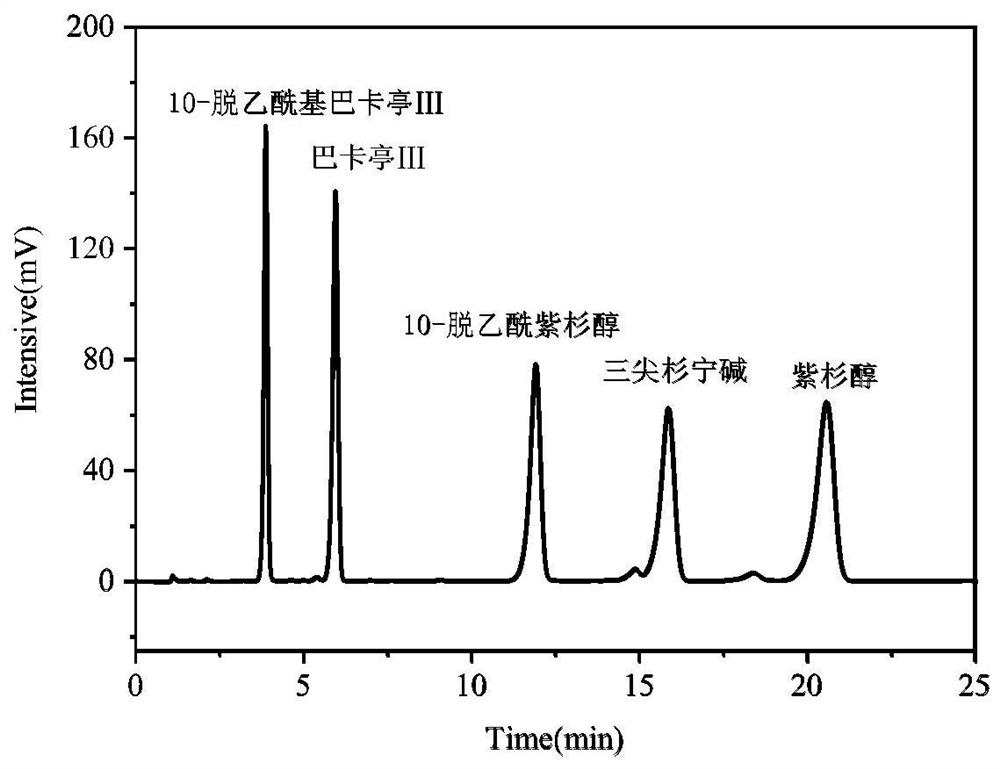

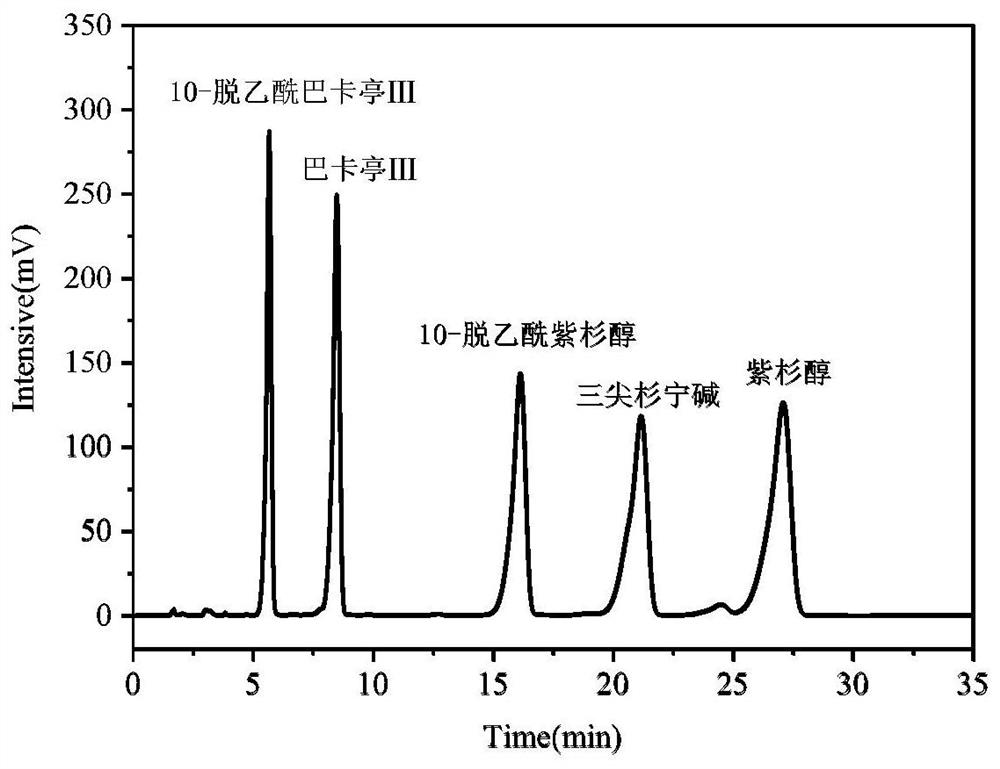

Method for separating paclitaxel by utilizing rosin-based bonded silica gel stationary phase

A technology for bonding silica gel and rosin base, which is applied in the field of high performance liquid chromatography, can solve the problems of unsatisfactory separation effect of paclitaxel and its analogs, low column efficiency of chromatographic columns, etc., and achieves increased spatial selectivity and good separation effect. , The effect of high solvent tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0034] First put 7.0g of silica gel into aqueous hydrochloric acid solution, reflux for 5 hours under the protection of nitrogen, wash with high-purity water until neutral, and dry in vacuum to obtain the activation of silica gel; then 5.5g of activated silica gel, 50.0g of anhydrous toluene, 5.0g of 3 -(methacryloyloxy)propyltrimethoxysilane was added to a three-necked flask, stirred magnetically, refluxed for 5 hours, washed with toluene and acetone, and dried in vacuum to obtain silica gel modified with silane coupling agent; finally, 5.0 g of disproportionated rosin (β- Dissolve acryloyloxyethyl) ester in ethyl acetate, then add 5.0g of silane coupling agent to modify silica gel, disperse by ultrasonic, add 0.08g of initiator azobisisobutyronitrile, protect with nitrogen, and react at 75°C for 6h to obtain Rosin-based bonded silica stationary phase.

preparation Embodiment 2

[0036] First put 15.0g of silica gel into aqueous hydrochloric acid solution, reflux for 3h under the protection of argon, wash with high-purity water until neutral, and dry in vacuum to obtain the activation of silica gel; then 14.0g of activated silica gel, 70.0g of anhydrous toluene, 15.0g Add (3-mercaptopropyl) trimethoxysilane into a three-necked flask, stir magnetically, reflux for 7 hours, wash with toluene and methanol, and dry in vacuo to obtain a silane coupling agent-modified silica gel; finally, 14.0 g of dehydroabietic acid (β - Dissolve acryloyloxyethyl) ester in butyl acetate, then add 13.0g of silane coupling agent to modify silica gel, disperse by ultrasonic, add 0.15g of initiator dibenzoyl peroxide, and react at 70°C under the protection of argon After 8 hours, a rosin-based bonded silica gel stationary phase was obtained.

preparation Embodiment 3

[0038]First put 25.0g of silica gel into aqueous hydrochloric acid solution, reflux for 8 hours under the protection of nitrogen, wash with high-purity water until neutral, and dry in vacuum to obtain the activation of silica gel; then 23.0g of activated silica gel, 210.0g of anhydrous toluene, 20.0g ( Add 3-mercaptopropyl)triethoxysilane into a three-necked flask, stir magnetically, reflux for 8 hours, wash with toluene and ethanol, and dry in vacuo to obtain silane coupling agent-modified silica gel; In ethyl acetate, add 23.0g silane coupling agent to modify silica gel, ultrasonically disperse, add 0.35g initiator tert-butyl hydroperoxide, and react at 78°C for 8h under nitrogen protection to obtain rosin-based bonded silica gel stationary phase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com