Preparation method and application of functionalized group-adjustable carbon nanotube loaded iron phthalocyanine composite material

A technology of carbon nanotubes and composite materials, applied in the field of electrochemistry, can solve the problems of single-atom catalysts such as low plasticity, poor environmental adaptability, and introduction of functional groups, and achieve the effects of excellent electrocatalytic oxygen reduction performance, low cost, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

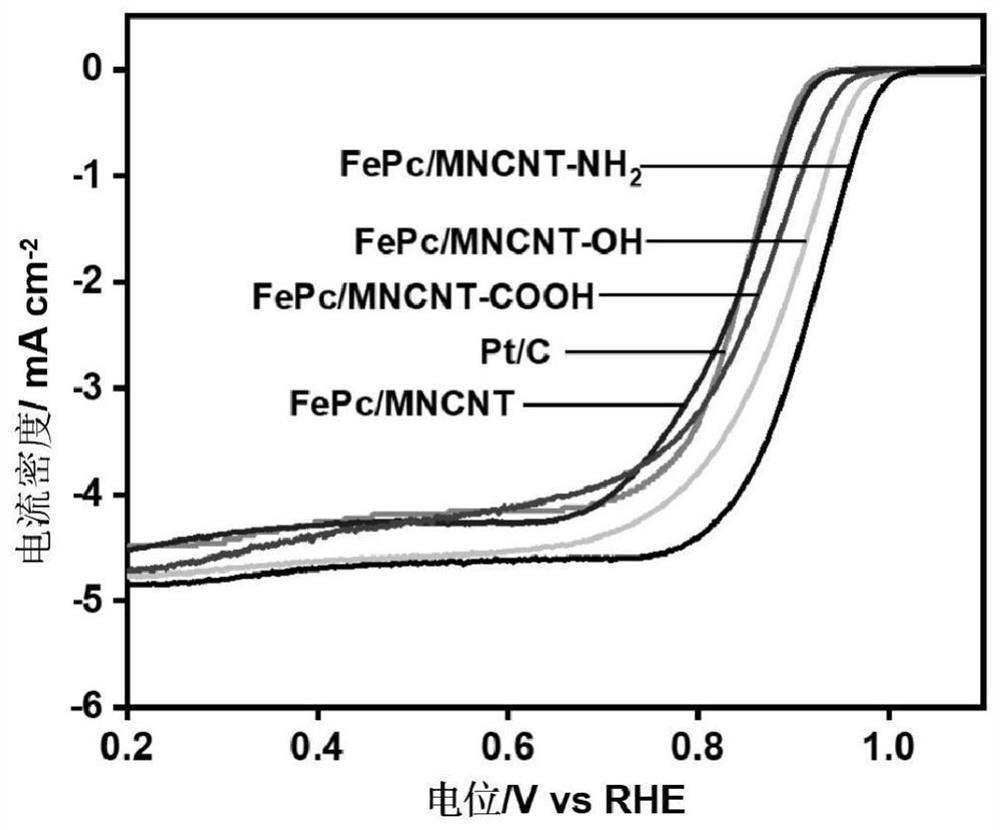

[0036] Iron Phthalocyanine FePc / MNCNT-NH Supported by Aminated Multi-walled Carbon Nanotubes 2 Preparation of:

[0037] (1) Dissolve 0.5 g of iron phthalocyanine in 50 mL of ethanol, and ultrasonicate for 1 h at room temperature to obtain a uniform dark green liquid, which is designated as mixture I.

[0038] (2) Take 2.5g of aminated carbon nanotube MNCNT-NH 2 Add it into 50ml of ethanol, and ultrasonicate at room temperature for 1h to obtain a uniformly dispersed black dispersion, which is designated as Mixture II.

[0039] (3) Add the above-mentioned mixture I to the mixture II, after mixing, sonicate for 1h, then magnetically stir at room temperature for 24h under the protection of nitrogen, and after standing for 1h, a black suspension is obtained. Suction filter the suspension, and use it several times. Washed with ethanol, and finally dried in a vacuum dryer at 60°C for 12 hours to obtain a black powder product aminated multi-walled carbon nanotubes loaded with iron p...

Embodiment 2

[0045] Preparation of hydroxylated multi-walled carbon nanotubes supported iron phthalocyanine FePc / MNCNT-OH:

[0046] (1) Dissolve 0.1 g of iron phthalocyanine in 50 mL of DMF, and ultrasonicate for 0.5 h at room temperature to obtain a uniform dark green liquid, which is designated as Mixture I.

[0047] (2) Add 1 g of hydroxylated carbon nanotubes MNCNT-OH to 50 ml of DMF, and ultrasonicate for 0.5 h at room temperature to obtain a uniformly dispersed black dispersion liquid, which is designated as mixture II.

[0048] (3) Add the above-mentioned mixture I to the mixture II, and after mixing, sonicate for 1 hour, then magnetically stir at room temperature for 12 hours under the protection of nitrogen, and after standing for 1 hour, a black suspension is obtained. Washed with ethanol and DMF, and finally dried in a vacuum dryer at 60°C for 12 hours to obtain a black powder product of hydroxylated multi-walled carbon nanotubes loaded with iron phthalocyanine FePc / MNCNT-OH.

Embodiment 3

[0050] Preparation of iron phthalocyanine FePc / MNCNT-COOH supported by carboxylated multi-walled carbon nanotubes:

[0051] (1) Dissolve 0.05 g of iron phthalocyanine in 50 mL of dimethyl sulfoxide, and sonicate for 1 h at room temperature to obtain a uniform dark green liquid, which is designated as mixture I.

[0052] (2) Add 0.4 g of carboxylated carbon nanotube MNCNT-COOH into 50 ml of dimethyl sulfoxide, and ultrasonicate for 1 h at room temperature to obtain a uniformly dispersed black dispersion liquid, which is designated as mixture II.

[0053] (3) Add the above-mentioned mixture I to the mixture II, after mixing, sonicate for 0.5h, then magnetically stir at room temperature for 20h under the protection of nitrogen, and after standing for 1h, a black suspension is obtained, and the suspension is suction-filtered for several times Wash with ethanol and dimethyl sulfoxide, and finally dry in a vacuum dryer at 60°C for 12 hours to obtain a black powder product carboxylat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com