A kind of m-aminobenzoic acid spherical crystal and preparation method thereof

A technology of aminobenzoic acid and spherical crystals, which is applied in the preparation of cyanide reaction, chemical instruments and methods, and the preparation of organic compounds, etc. It can solve the problems of poor chemical stability, high production cost, and easy agglomeration of products, and achieve fluidity Improvement, non-perishability, chemical stability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

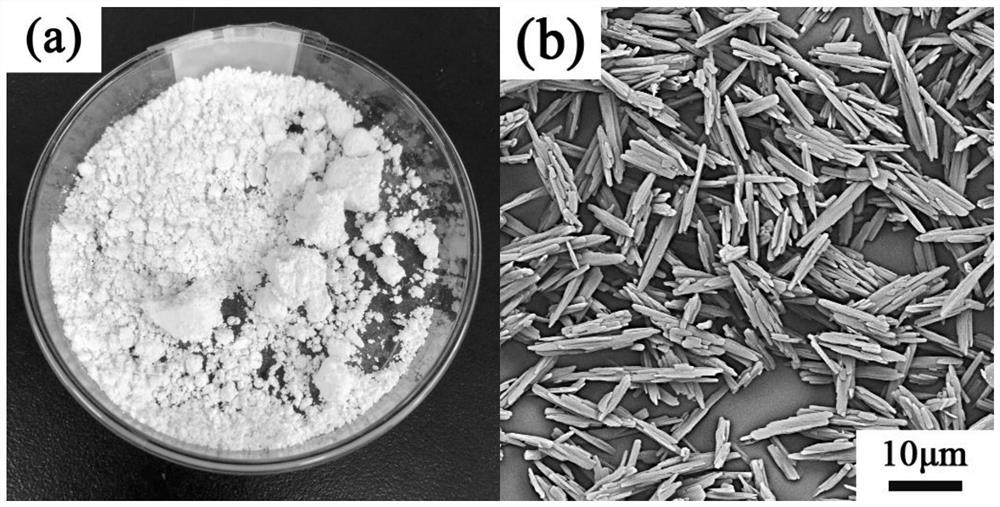

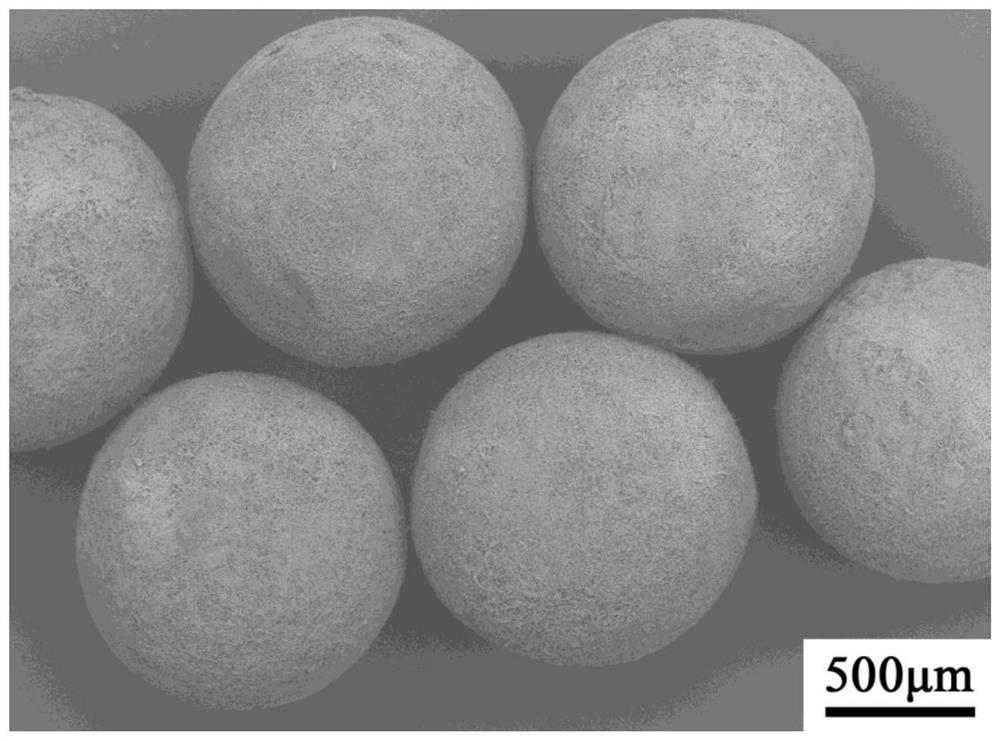

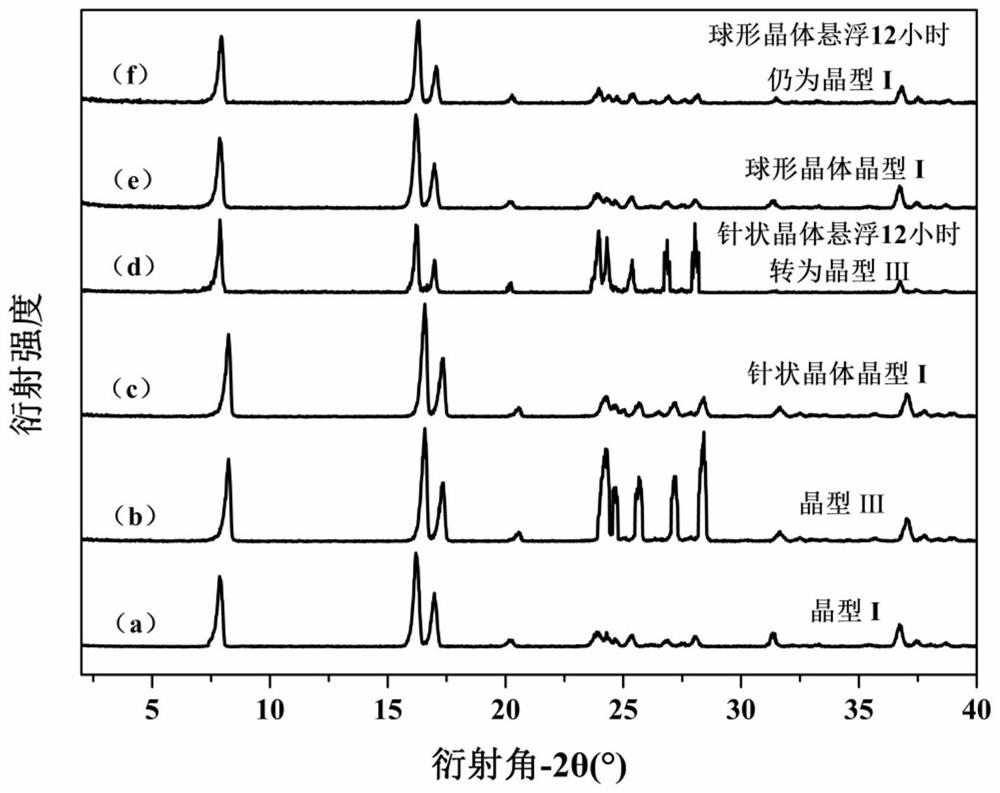

[0064] At 60°C and 250r / min stirring speed, 10g m-aminobenzoic acid crystal form I raw material was dissolved in 100g isopropanol to prepare m-aminobenzoic acid solution, the solution concentration was 0.091g / g solution, at 3°C / 10min Cool the solution down to 10°C at a cooling rate, continue stirring at 250 r / min until crystals emerge, and continue stirring at constant temperature for 40 minutes to make the crystals coalesce into balls. At this time, the density of the crystal slurry is 0.078 g / g of the solution, and then the crystal slurry is filtered, washed with water, Blast drying at 50°C for 12h, the spherical crystals of m-aminobenzoic acid can be obtained. The purity of the spherical crystals of m-aminobenzoic acid obtained by testing is 98.1%, and the volume average particle size is 1.22mm. figure 2 As shown in the figure, the angle of repose is 25.8°, the fluidity of the product is greatly improved, and the post-processing such as filtration, washing, drying, packagi...

Embodiment 2

[0066] Under the stirring speed of 65°C and 300r / min, 13g of m-aminobenzoic acid crystal form I was dissolved in 100g of ethylene glycol to prepare m-aminobenzoic acid solution, the solution concentration was 0.115g / g solution, at 5°C / 10min The solution was cooled to 5°C at a cooling rate of 100 rpm, stirring was continued for 300 r / min until crystals emerged, and the crystals were agglomerated into balls by stirring at a constant temperature for 60 min. At this time, the density of the crystal slurry was 0.080 g / g of the solution, and then the crystal slurry was filtered and washed with water. , 50 ℃ blast drying for 12h, the spherical crystals of m-aminobenzoic acid can be obtained. The purity of the obtained m-aminobenzoic acid spherical crystals is 98.0%, the volume average particle size is 0.63mm, the angle of repose is 24.4°, and the fluidity of the product is greatly improved. The agglomeration rate of spherical crystals is 6.0%, which is far less than 58-64% of needle-...

Embodiment 3

[0068] Under the stirring speed of 50 ° C and 200 r / min, 11 g of m-aminobenzoic acid crystal form I was dissolved in 100 g of ethanol to prepare a m-aminobenzoic acid solution with a concentration of 0.099 g / g solution. The solution was cooled to 10 °C at a rate of 200 r / min until the crystals appeared, and the constant temperature stirring was continued for 50 minutes to make the crystals coalesce into balls. ℃ blast drying for 10h, the spherical crystals of m-aminobenzoic acid can be obtained. The purity of the obtained m-aminobenzoic acid spherical crystals is 98.2%, the volume average particle size is 0.55mm, the angle of repose is 27.7°, and the fluidity of the product is greatly improved. The agglomeration rate of spherical crystals is 6.5%, which is far less than 58-64% of needle-like crystals; the tap density of spherical crystals is 0.35g / cm 3 , which improves the storage and transportation efficiency of m-aminobenzoic acid products; the specific surface area of sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| angle of repose | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com