Push rod type optimizing and accurate cutting-off saw

A push rod and sawing technology, which is applied in the direction of circular saws, sawing components, sawing equipment, etc., can solve the problems of low positioning accuracy, inability to press and hold, and inability to send and position wood.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

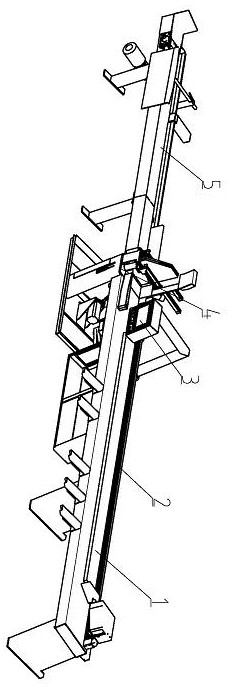

[0042] exist figure 1 The preferred push rod fine-cutting saw shown in this cross-cutting saw includes a pusher 2, a sawing machine 4 and a sawing material sorter 5, and a pusher is respectively arranged on the left and right sides of the sawing machine 4 2 and sawing material sorting machine 5. The wood to be sawed 1 is sent to the sawing machine 4 by the precise push and feeding of the pusher 2, and is cut off by horizontal sawing. ; Therefore, the pusher 2, the sawing machine 4 and the sawing material sorter 5 are arranged in sequence from front to back along the timber sawing path. The sensors and driving motors of the pusher 2, the sawing machine 4 and the sawing material sorting machine 5 are all electrically connected to the intelligent controller 3, and the intelligent controller 3 also controls the sorting cylinder of the sawing material sorting machine 5 53 Sorting actions.

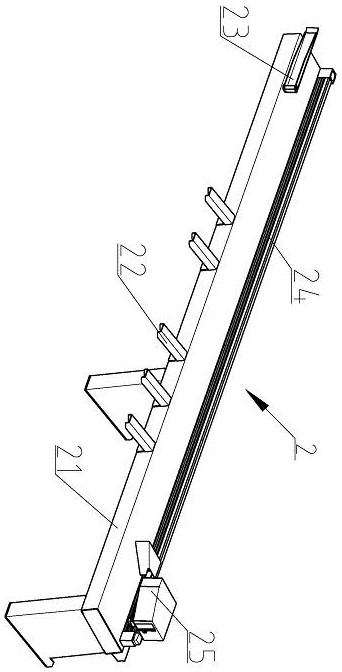

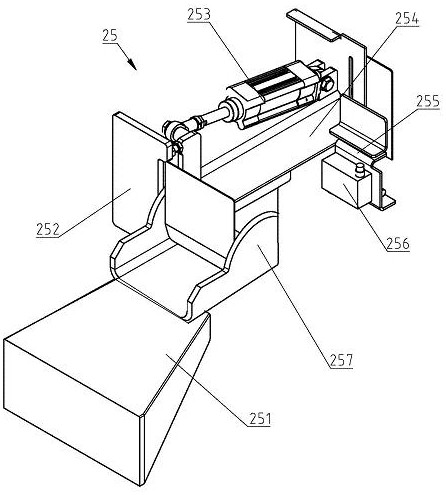

[0043] Such as figure 2 In the pusher 2 shown, a pusher electric cylinder 24 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com