Second rotating shaft group of three-axis linked large circuit board testing fixture

A three-axis linkage, test fixture technology, applied to the casing of the measuring device, etc., can solve the problems of clamping offset, manual clamps cannot be stably and effectively clamped and positioned, and large circuit boards are not very convenient for handling and testing. The effect of holding positioning, simple and practical structure, convenient detection and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

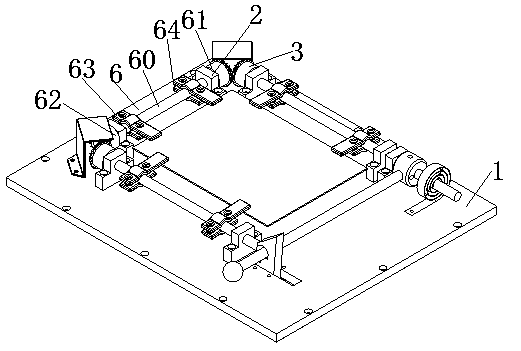

[0008] see figure 1 , the embodiment of the present invention includes:

[0009] A second rotating shaft group of a three-axis linkage large-scale circuit board test fixture, the second rotating shaft group of the three-axis linkage large-scale circuit board test fixture includes a second rotating shaft 60, a front bevel gear 61 of the second rotating shaft, and a second rotating shaft rear The bevel gear 62, the upper pressing plate 63 of the second rotating shaft and the lower fixing plate 64 of the second rotating shaft, the two ends of the second rotating shaft 60 are installed on the general base plate 1 through the rotating shaft seat 2, and the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com