Top cover plastic case pressing equipment for assembling the driver

A technology for pressing equipment and drivers, applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of easy displacement of semi-finished products of the driver, affecting assembly quality/effect, and difficulty in guaranteeing work quality, etc., and achieves high versatility and practicability. Good work quality and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

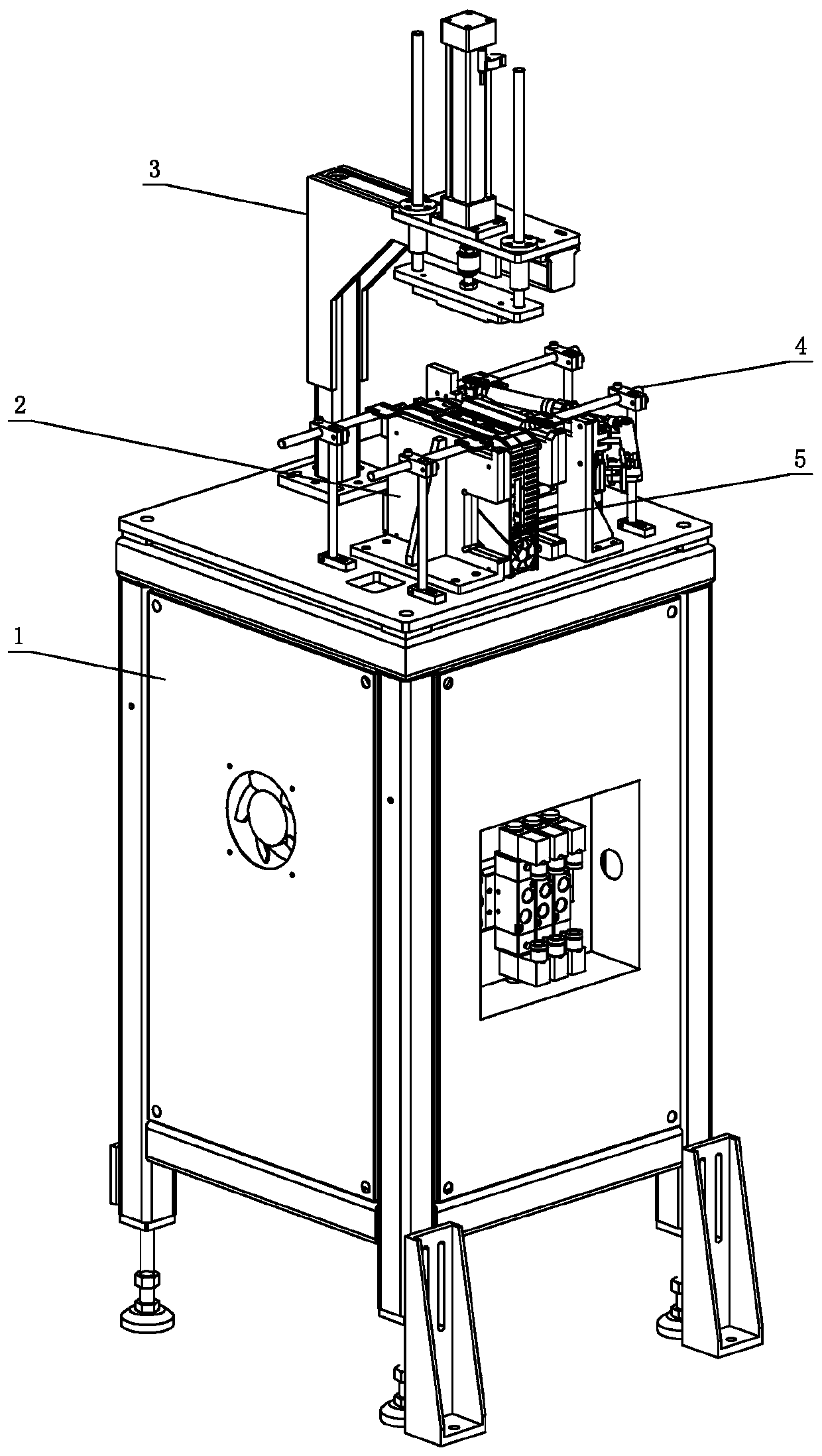

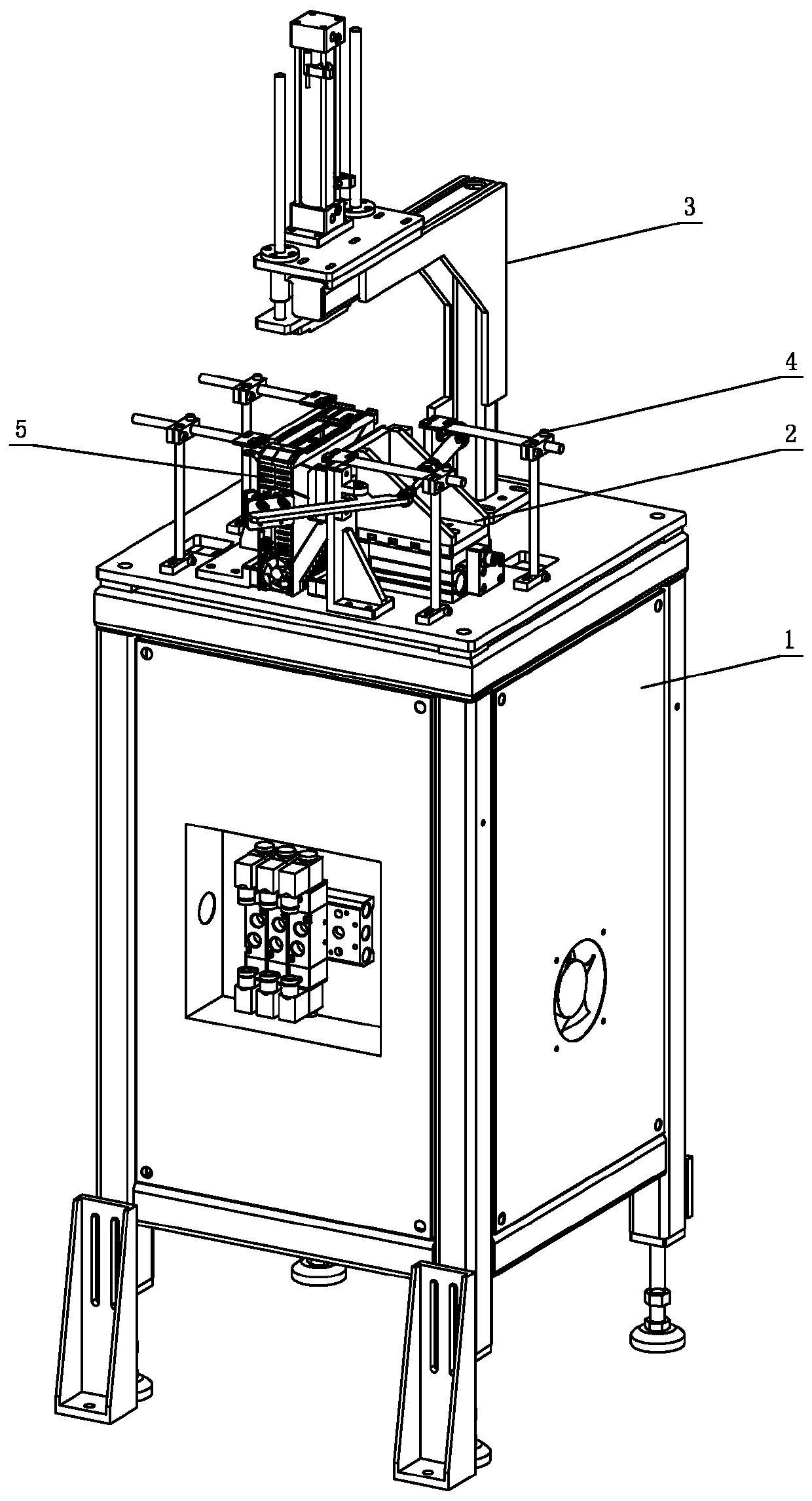

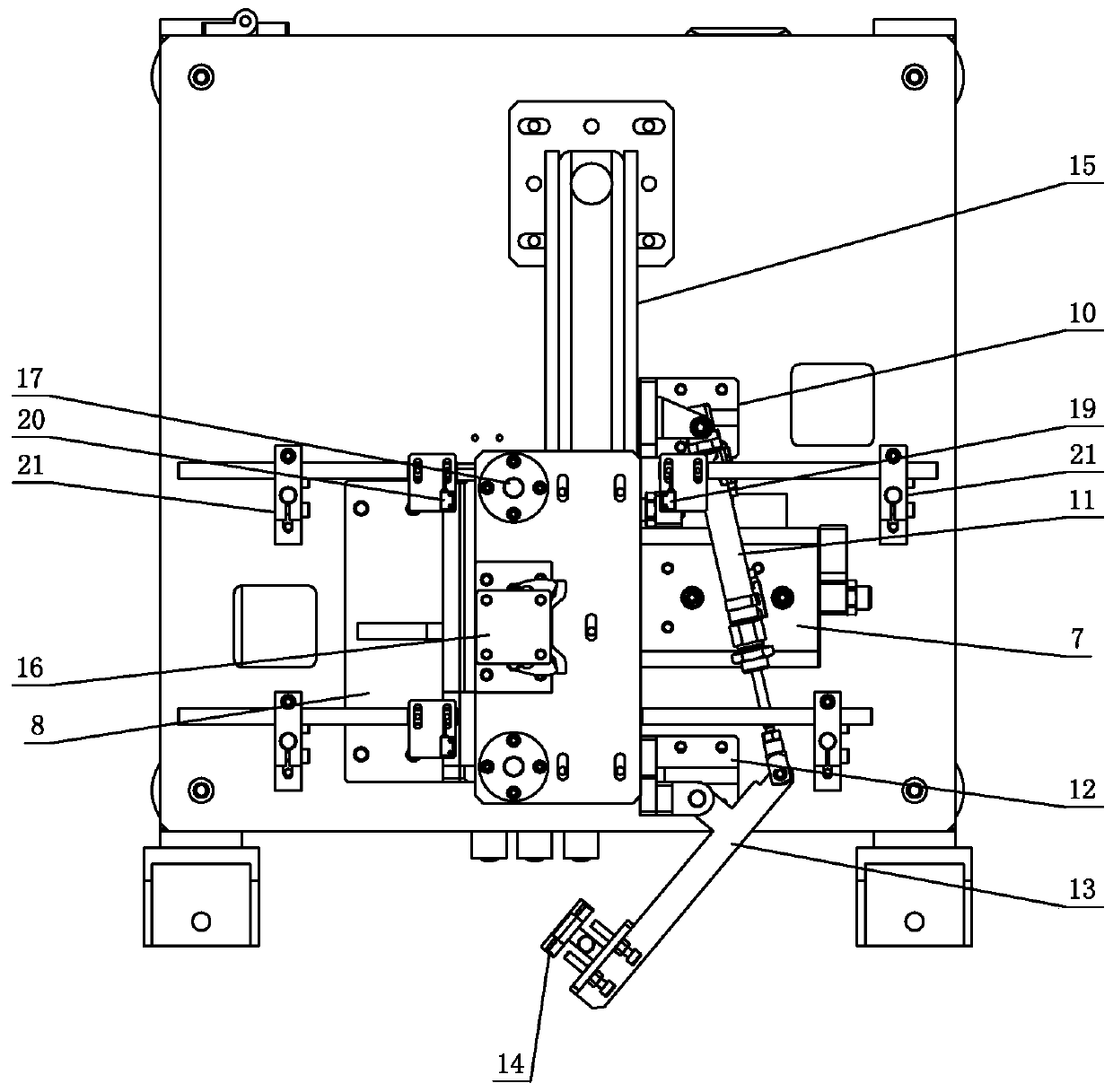

[0029] see Figure 1-Figure 12 , the upper cover molded case pressing equipment used for assembling the driver includes a pressing workbench 1, the pressing workbench 1 is provided with a positioning reference mechanism 2 and a lower pressing mechanism 3, and the positioning reference mechanism 2 is located below the lower pressing mechanism 3 Among them, the positioning reference mechanism 2 can limit the horizontal direction of the driver semi-finished product 5.1 to ensure that it will not deviate in the horizontal direction; the pressing mechanism 3 can press the upper cover plastic case 5.2 and the driver semi-finished product 5.1 to form a The finished driver 5; specifically, the positioning reference mechanism 2 includes a side pressure positioning assembly and an end pressure positioning assembly that do not interfere with each other; the side pressure positioning assembly includes a side pressure cylinder 6, a first side pressure plate 7 and a second side pressure plat...

no. 2 example

[0039] The upper cover molded casing pressing equipment used for assembling the driver is different from the first embodiment in that: the side pressure positioning component adopts another scheme: two sets of side pressure cylinders 6 are provided, and they are respectively connected with the first side pressure plate 7 and the second side pressure plate. The two side pressing plates 8 are provided as a set; the first side pressing plate 7 and the second side pressing plate 8 are respectively slidably set relative to the pressing workbench 1, and the cylinder body of one side pressing cylinder 6 is fixedly arranged relative to the pressing workbench 1, and the rod body is connected to the first side Pressing plate 7 drives it to reciprocate and slide relative to pressing table 1, the cylinder body of the other side pressing cylinder 6 is fixed relative to pressing table 1, and the rod body is connected to the second side pressing plate 8 and drives it to reciprocate sliding rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com