Preparation method of zinc-iron composite oxide loaded activated carbon desulfurizer

A composite oxide and activated carbon technology, which is applied in chemical instruments and methods, separation methods, and other chemical processes, can solve the problems of desulfurization desulfurization performance of desulfurizers, reduction of sulfur capacity, uneven loading of active components, etc. Capacity and desulfurization accuracy, improve load uniformity, and prevent equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A preparation method of zinc-iron composite oxide loaded activated carbon desulfurizer, the steps are as follows:

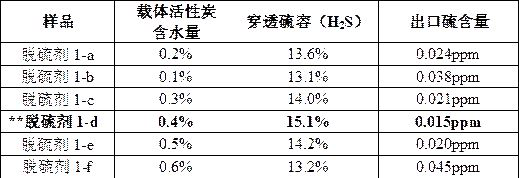

[0053] S1. Take 3000g of φ4mm activated carbon, and measure in the laboratory that its water content is 0.2wt%, its bulk density is 0.45kg / L, its pore volume is 0.51mL / g, and its adsorption saturation is 90%;

[0054] S2, get S1 activated carbon 500g, its water content is 0.2 wt%; Get S1 activated carbon 500g, carry out vacuum treatment (vacuum negative pressure is-0.2MPa, pumping time 15min), make the water content of activated carbon be controlled at 0.1wt%; Take 500g of S1 activated carbon for 0.2h -1 Water vapor is passed into the activated carbon at a space velocity of 2.5h to make the water content reach 0.3wt%; take 500g of S1 activated carbon, -1 Water vapor is passed into the activated carbon at a space velocity of 2.5h to make the water content reach 0.4wt%; take 500g of S1 activated carbon, 1 Water vapor is passed into the activated carbon at ...

Embodiment 2

[0066] A preparation method of zinc-iron composite oxide loaded activated carbon desulfurizer, the steps are as follows:

[0067] S1. Take 3000g of φ4mm activated carbon, and measure in the laboratory that its water content is 0.2wt%, its bulk density is 0.45kg / L, its pore volume is 0.51mL / g, and its adsorption saturation is 90%;

[0068] S2, with 0.4h -1 The space velocity is passed into the S1 activated carbon for 2.5h to make the water content reach 0.4wt%, and then the activated carbon is divided into 6 parts, each 500g;

[0069] S3, dissolving zinc sulfate, iron sulfate and urea into deionized water to form a mixed solution of zinc and iron salts. In the solution, the concentration of zinc ions is 0.01mol / l, the concentration of iron ions is 0.01mol / l, and the excess of urea is 2 times;

[0070] S4. Pour the mixed solution of zinc-iron salt obtained in S3 into the drum machine with 6 parts of 500g of activated carbon in S2, the mass ratio of zinc-iron salt solution to a...

Embodiment 3

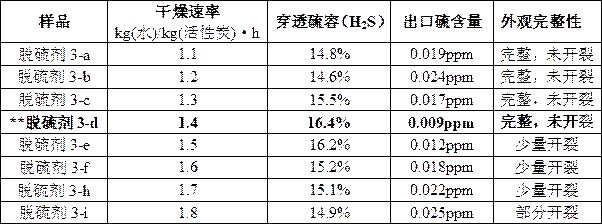

[0079] A preparation method of zinc-iron composite oxide loaded activated carbon desulfurizer, the steps are as follows:

[0080] S1. Take 4000g of φ4mm activated carbon, and measure in the laboratory that its water content is 0.2wt%, its bulk density is 0.45kg / L, its pore volume is 0.51mL / g, and its adsorption saturation is 90%;

[0081] S2, with 0.4h -1 The space velocity is passed into the S1 activated carbon for 2.5h to make the water content reach 0.4wt%, and then the activated carbon is divided into 8 parts, each 500g;

[0082] S3, dissolving zinc sulfate, iron sulfate and urea into deionized water to form a mixed solution of zinc and iron salts. In the solution, the concentration of zinc ions is 0.01mol / l, the concentration of iron ions is 0.01mol / l, and the excess of urea is 2 times;

[0083] S4, the mixed solution of the zinc-iron salt obtained in S3 is poured into the tumbler with the gac of 8 parts of 500g in S2 respectively, and the zinc-iron salt solution

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com