Multilayer composite material with strong microwave absorption in GHz interval and preparation method thereof

A multi-layer composite material and microwave absorption technology, which is applied in the field of microwave-absorbing materials, can solve problems such as damage to wave-absorbing properties and reduced magnetic susceptibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

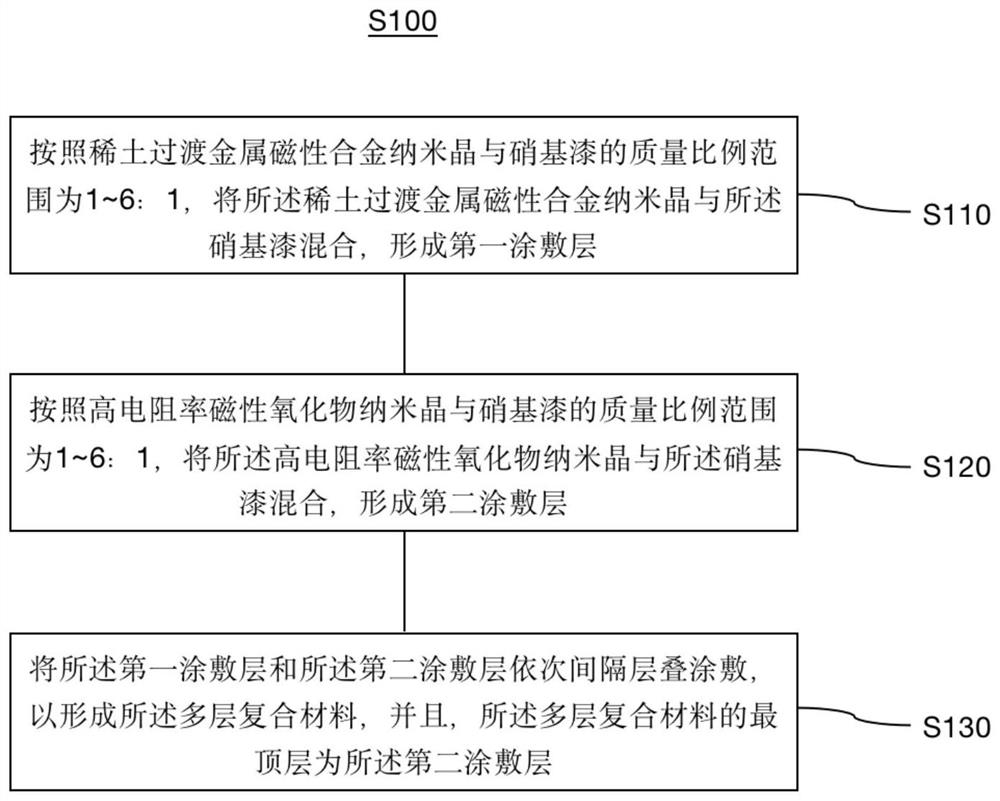

[0048] like figure 1 As shown, another aspect of the present invention provides a preparation method S100 of a multilayer composite material with strong microwave absorption in the GHz range, which specifically includes the following steps S110-S130:

[0049] S110. According to the mass ratio of the rare earth transition metal magnetic alloy nanocrystals and the lacquer in the range of 1-6:1, mix the rare earth transition metal magnetic alloy nanocrystals with the lacquer to form a first coating layer.

[0050] It should be noted that the rare earth transition metal magnetic alloy nanocrystals in this step are formed by the following method: use the elemental alloy corresponding to each element in the rare earth transition metal magnetic alloy nanocrystal as raw material, and use electric arc furnace melting or induction furnace melting method for melting Ingots form alloy ingots. The raw material is heat-treated at a temperature range of 900°C to 1400°C for 12h to 360h to fo...

Embodiment 1

[0068] In this example, the preparation method of the multi-layer composite material with strong microwave absorption in the GHz range comprises the following steps:

[0069] S1, the rare earth transition metal alloy adopts Ce 2 Fe 17 N x (x~3), using the elemental alloy as raw material, using the electric arc furnace melting method to prepare alloy ingots, and then heat-treating at 1000 ° C for 7 days, taking out the alloy ingots, after coarse crushing, ball milling in a high-energy ball mill for 24 hours to obtain master alloys. At 450°C, through a nitrogen atmosphere for 4h, absorb nitrogen treatment, and finally obtain Ce 2 Fe 17 N x (x~3). After that, the Ce 2 Fe 17 N x (x~3) and nitro paint are mixed according to the weight ratio of 2:1, and stirred evenly with a turbo mixer at a stirring rate of 100 rpm to form the first coating layer.

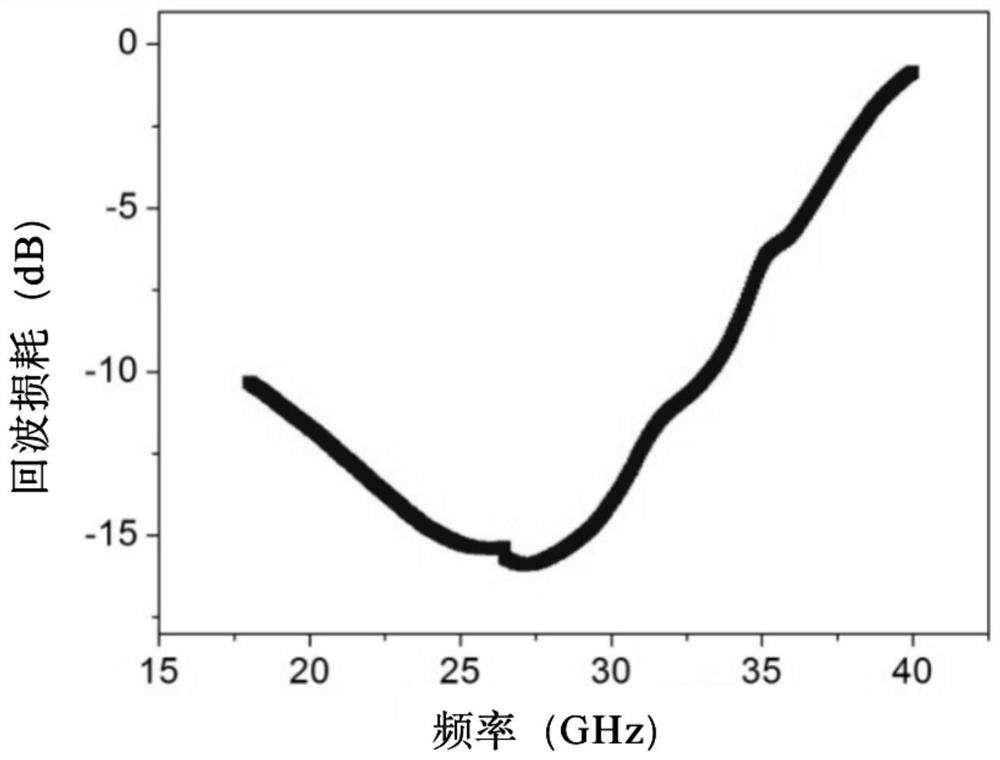

[0070] S2, high resistivity magnetic oxide using SrFe 10.6 Ni 0.7 Ru 0.7 o 19 .Using Sr, Fe, Ni oxides and Ru simple subs...

Embodiment 2

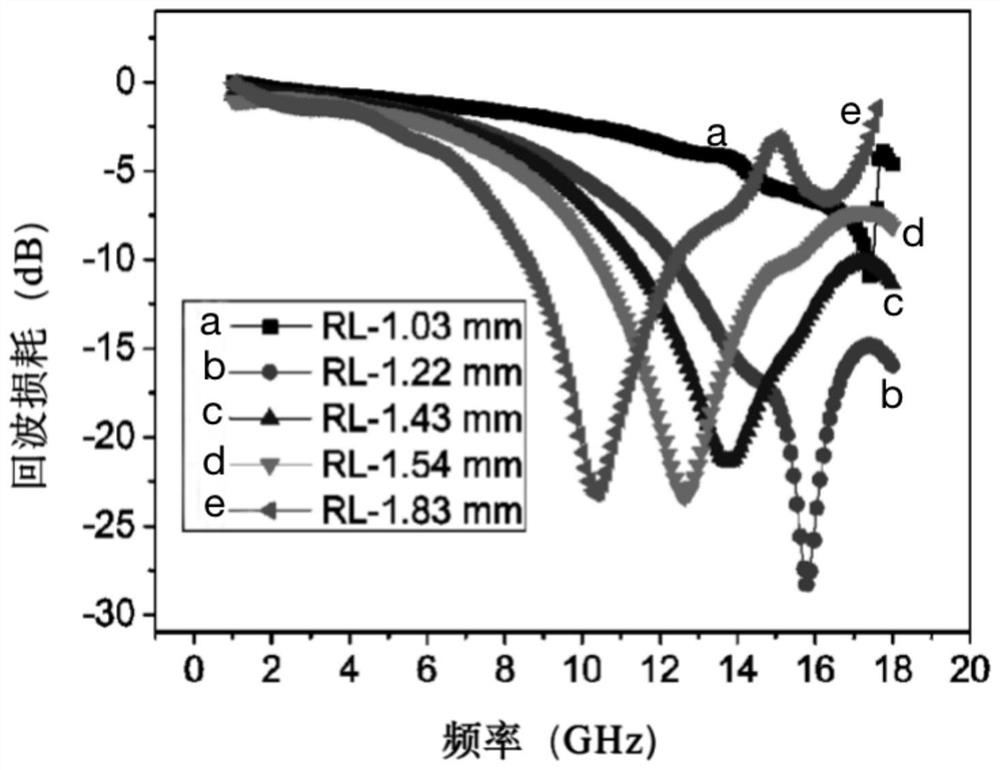

[0075] read on image 3 , this example shows the effect of different total coating thicknesses on the wave-absorbing characteristics, specifically showing that changing the Ce 2 Fe 17 N x (x~3) Nitro paint layer (first coating layer) and SrFe 10.6 Ni 0.7 Ru 0.7 o 19 The effect of the total thickness of the layer (second coating layer) on the absorbing properties. Among them, curve a represents a total thickness of 1.03 mm, curve b represents a total thickness of 1.22 mm, curve c represents a total thickness of 1.43 mm, curve d represents a total thickness of 1.54 mm, and curve e represents a total thickness of 1.83 mm. according to image 3 It can be seen that when the total coating thickness is above 1.22mm, there is better wave-absorbing property, and, with the increase of the total coating layer thickness, the wave-absorbing interval moves. It can be seen that the multilayer composite obtained in this embodiment The material has better wave-absorbing properties than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com