Diaphragm and lithium battery using diaphragm

A lithium battery and diaphragm technology, applied in the field of diaphragms and lithium batteries using the diaphragm, can solve the problems of easy bending and deformation, internal resistance, deformation and unevenness, and achieve the avoidance of deformation and unevenness, high quality yield, and process steps and the effect of using a clear range of parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

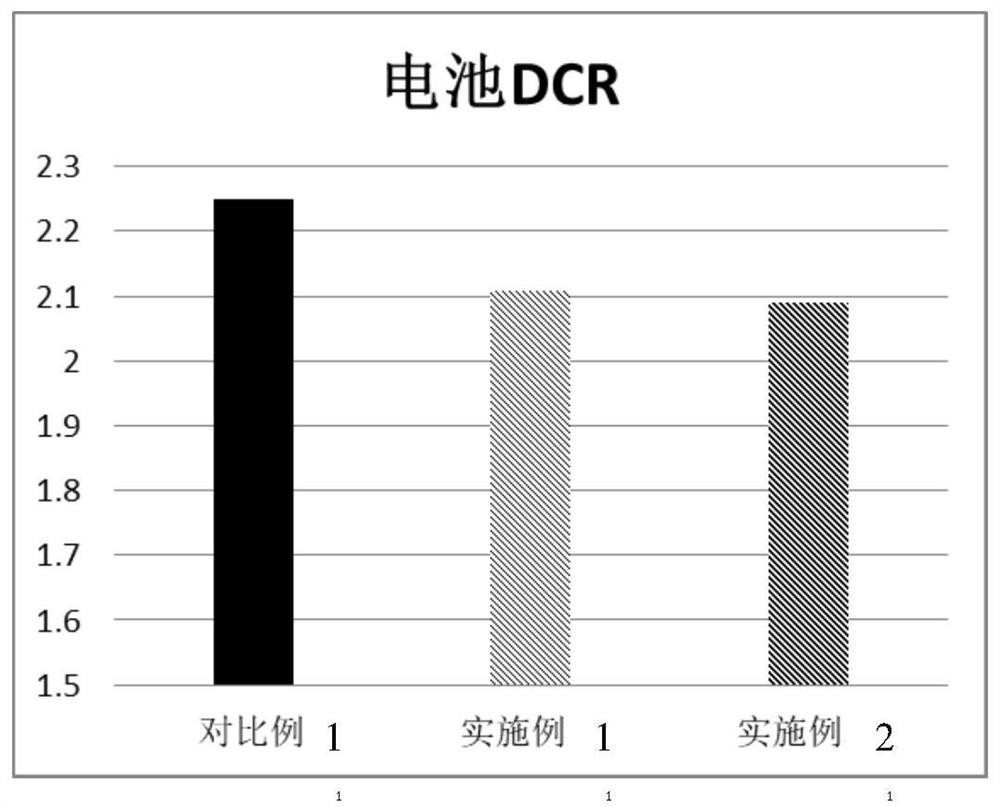

Embodiment 1

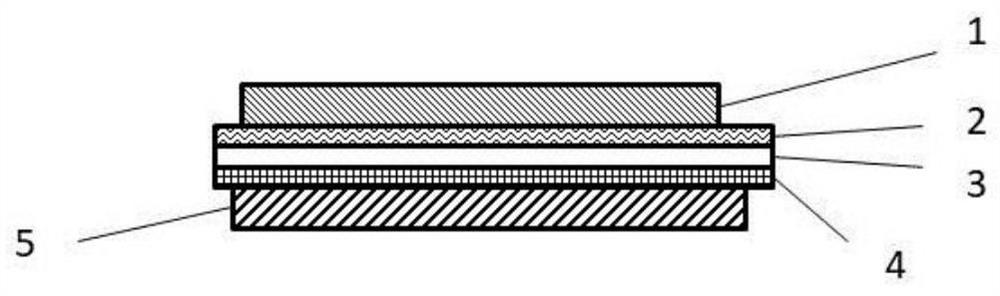

[0033] The preparation method of the diaphragm and the lithium battery using the diaphragm comprises the following preparation steps:

[0034] 1) Coating preparation: dissolving ceramic powder aluminum oxide and polymer polyvinylidene fluoride in solvent acetone and dispersing into a uniform slurry, the mass content of the ceramic and polymer is 10%, and it is used in the coating on the A side , the ratio of ceramics and polymers is 40%: 60%, for the B surface coating, the ratio of ceramics and polymers is 0%: 100%;

[0035] 2) Coating: apply the coating to the surface of the base film by coating equipment, first coat the A side, then dry, then coat the B side, and then dry to obtain the separator;

[0036] 3) Prepare the battery structure: prepare the lithium iron phosphate positive pole piece and the graphite negative pole piece by winding or lamination process, and bond the positive pole piece with the diaphragm A surface under the action of hot pressing, and the negative p...

Embodiment 2

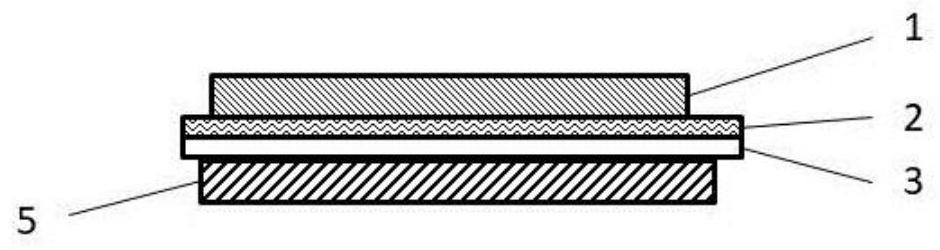

[0039] The difference from Example 1 is that the preparation method of the diaphragm and the lithium battery using the diaphragm includes the following preparation steps: 1) Preparation of coating: ceramic powder barium sulfate and polymer poly(vinylidene fluoride-co- Hexafluoropropylene) is dissolved in the solvent acetone and dispersed into a uniform slurry, and the mass content of the ceramics and the polymer is 15%. In the coating on the A side, the ratio of the ceramics and the polymer is 50%: 50%. In the paint on side B, the proportion of ceramics and polymers is 20%: 80%;

[0040] 2) Coating: apply the coating to the surface of the base film by coating equipment, first coat the A side, then dry, then coat the B side, and then dry to obtain the separator;

[0041] 3) Prepare the battery structure: prepare lithium nickel manganese oxide positive pole piece and lithium titanate negative pole piece by winding or stacking process, and bond the positive pole piece with the A ...

Embodiment 3

[0044]The difference from Example 1 is that the preparation method of the separator and the lithium battery using the separator includes the following preparation steps: 1) Preparation of coating: dissolving ceramic powder aluminum oxide and polymer polyvinylidene fluoride in a solvent Disperse into a homogeneous slurry in acetone, the mass content of said ceramics and polymers is 20%, for the coating on side A, the ratio of ceramics and polymers is 60%: 40%, used in the coating on side B, ceramics And the ratio of polymer is 30%:70%;

[0045] 2) Coating: apply the coating to the surface of the base film by coating equipment, first coat the A side, then dry, then coat the B side, and then dry to obtain the separator;

[0046] 3) Prepare the battery structure: prepare the positive pole piece and the negative pole piece by winding or stacking process, and bond the positive pole piece to the A side of the separator under the action of hot pressing, and bond the negative pole piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com