Sandwich type coke oven door prefabricated part and preparation method thereof

A prefabricated, sandwich-type technology, applied in the field of refractory materials, can solve problems such as low strength, poor thermal insulation of furnace doors, and impact on energy-saving effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

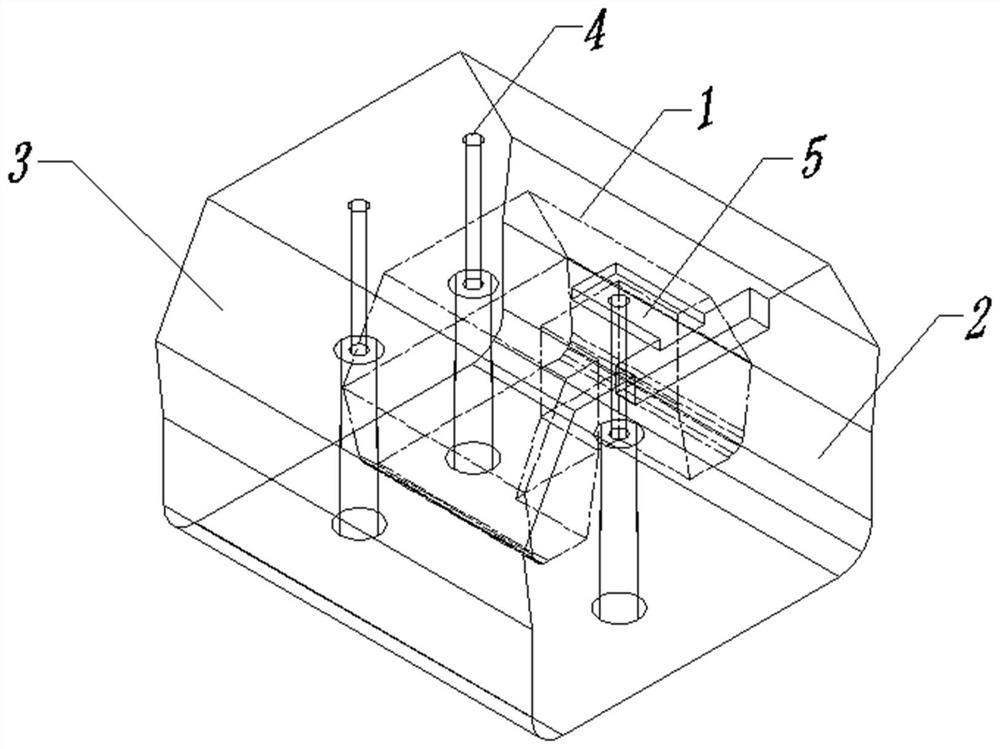

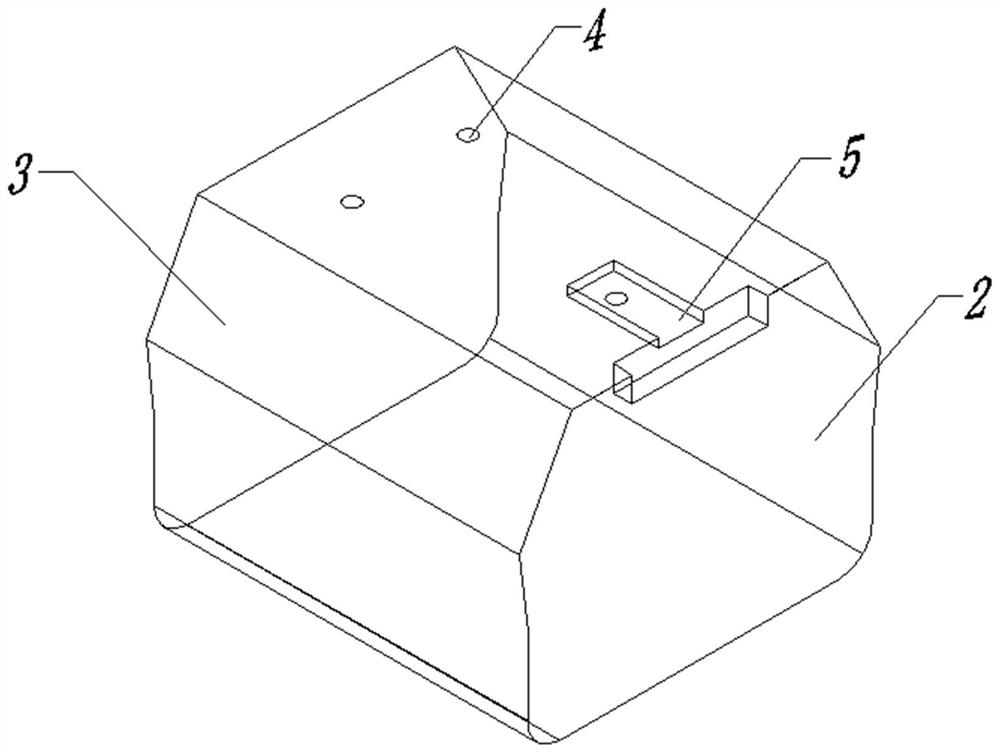

[0040] This embodiment provides a sandwich-type coke oven door prefabricated part, its structural perspective view and appearance are as follows figure 1 and figure 2 As shown, it specifically includes the thermal insulation inner lining 1, the working outer lining 2 and the refractory glaze layer 3 applied to the surface of the working surface of the working outer lining 2. The inner working outer lining 2 is provided with mounting bolt holes 4, and the installation surface of the working outer lining 2 ( That is, the side that is installed and connected with the furnace door frame shell, figure 1middle top surface) is provided with an installation groove 5, and the surface of the thermal insulation lining 1 is connected to the working surface parallel to the installation surface (i.e. figure 1 The distance between the middle bottom surface) is 150mm, the distance between the four sides is 80mm, the distance between the surface and the installation surface is 20mm, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Body dense | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com