Structure and process of grid-reinforced hydrogen storage pressure vessel impregnated with non-Newtonian fluid

A non-Newtonian fluid and grid structure technology, which is applied in the manufacture of pressure vessels, vessel structures, and outer walls of vessel structures, can solve problems such as poor overall performance of gas cylinders and no protection at both ends of the cylinder head. Achieve the effects of enhanced anti-instability, good structural stability, and good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] A technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

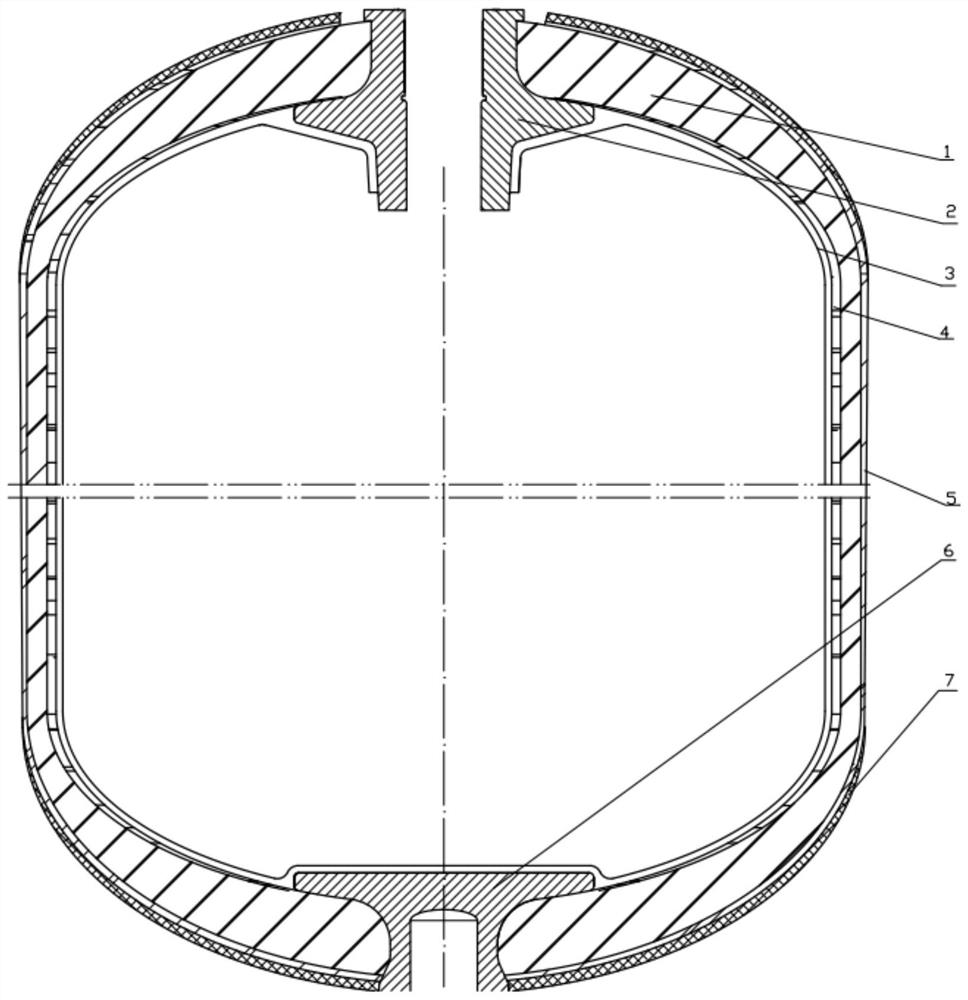

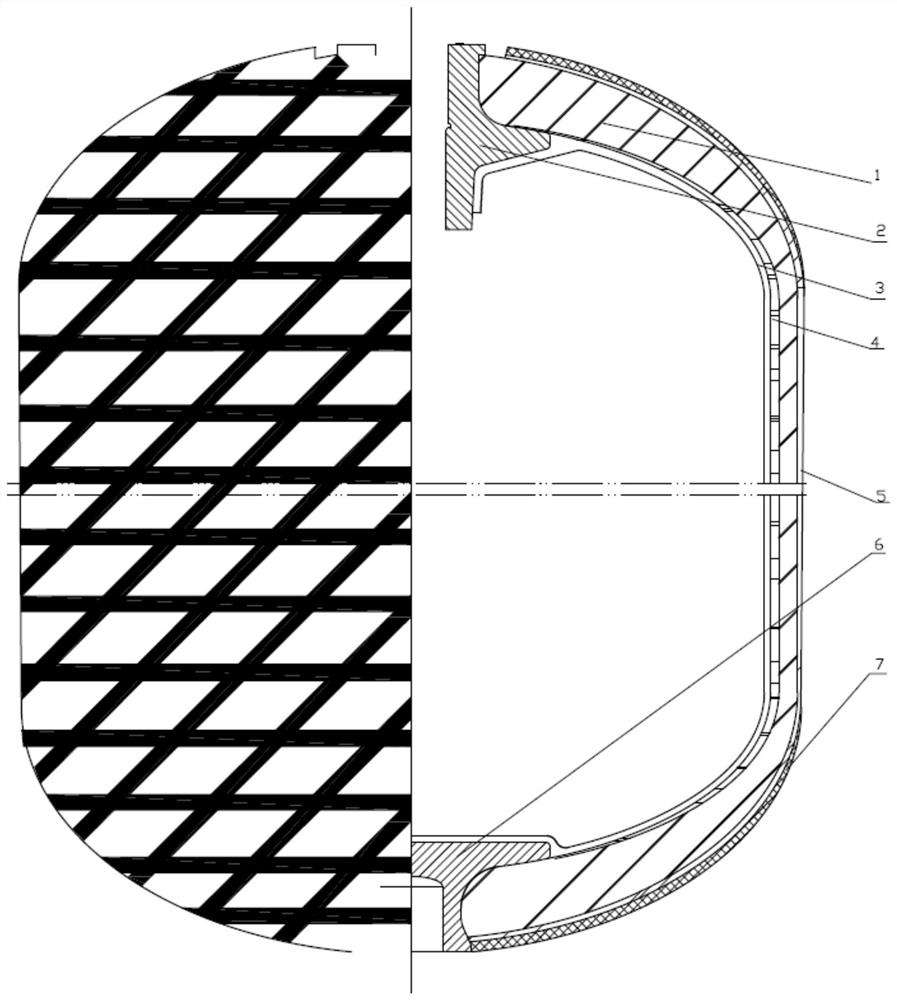

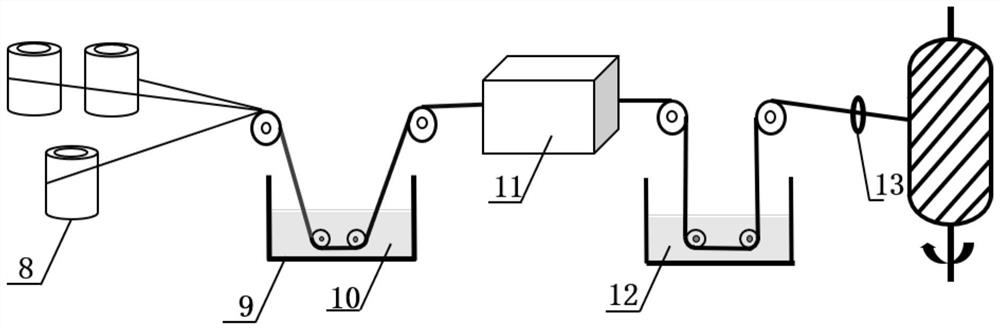

[0044] Such as Figure 1-Figure 2 As shown, the shape of the grid structure on the surface of the gas cylinder is shown in the figure, including the gas cylinder liner 3, the metal gas cylinder opening end 2 and the metal gas cylinder tail end 6, and the two ends of the gas cylinder liner 3 are respectively connected to the metal gas cylinder. The open end 2 of the metal gas cylinder and the tail end 6 of the metal gas cylinder also include fiber-reinforced resin-based composite material 4 that is prestressed and wound on the outer surface of the inner liner 3 of the gas cylinder, the open end 2 of the metal gas cylinder, and the outer surface of the tail end 6 of the metal gas cylinder. The outer surface of the reinforced resin-based composite material 4 continues to be wound with a grid structure reinforcement layer 1, a fiber protec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com