Thickener for supercritical carbon dioxide oil displacement as well as preparation method and application thereof

A carbon dioxide and thickening agent technology, which is applied in the field of thickeners and thickeners for supercritical carbon dioxide, can solve the problems of high concentration, high cloud point pressure of thickeners, affecting the oil displacement effect of supercritical carbon dioxide, etc. The effect of low cloud point pressure, excellent viscosity-increasing performance, and abundant raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

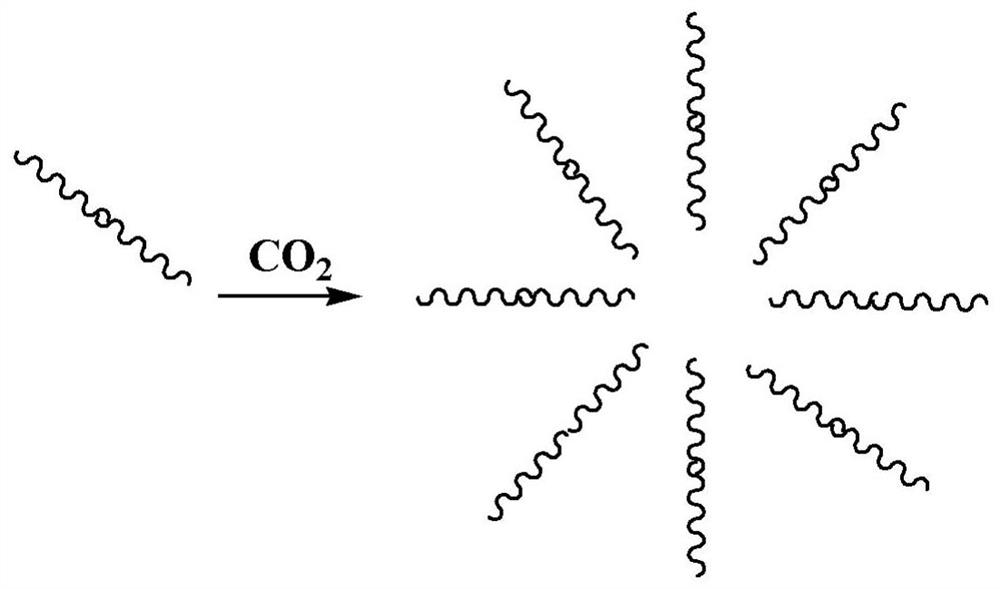

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a thickener, which is obtained by polymerizing the following polymerizable monomers under the action of an initiator:

[0047] Polymerized monomers: dodecafluoroheptyl methacrylate, 2-(dimethylamino) ethyl methacrylate and styrene, the molar percentages in the polymerized monomers are 58%, 15% and 27% respectively.

[0048] Initiator: azobisisoheptanonitrile, the dosage is 4.8×10 of the total monomer molar content -3 .

[0049] The polymerization reaction temperature was 55° C., and the reaction time was 24 hours.

[0050] Take the product and place it in a high-temperature and high-pressure viscometer, and after it is uniformly dissolved in supercritical carbon dioxide at 45°C, the measured cloud point pressure is 14MPa, and the solution viscosity is 0.74mPa·s.

Embodiment 2

[0052] This embodiment provides a thickener, which is basically the same as in Example 1, except that the amount of the initiator azobisisoheptanonitrile is 4.36×10 of the total molar content of the monomers. -5 .

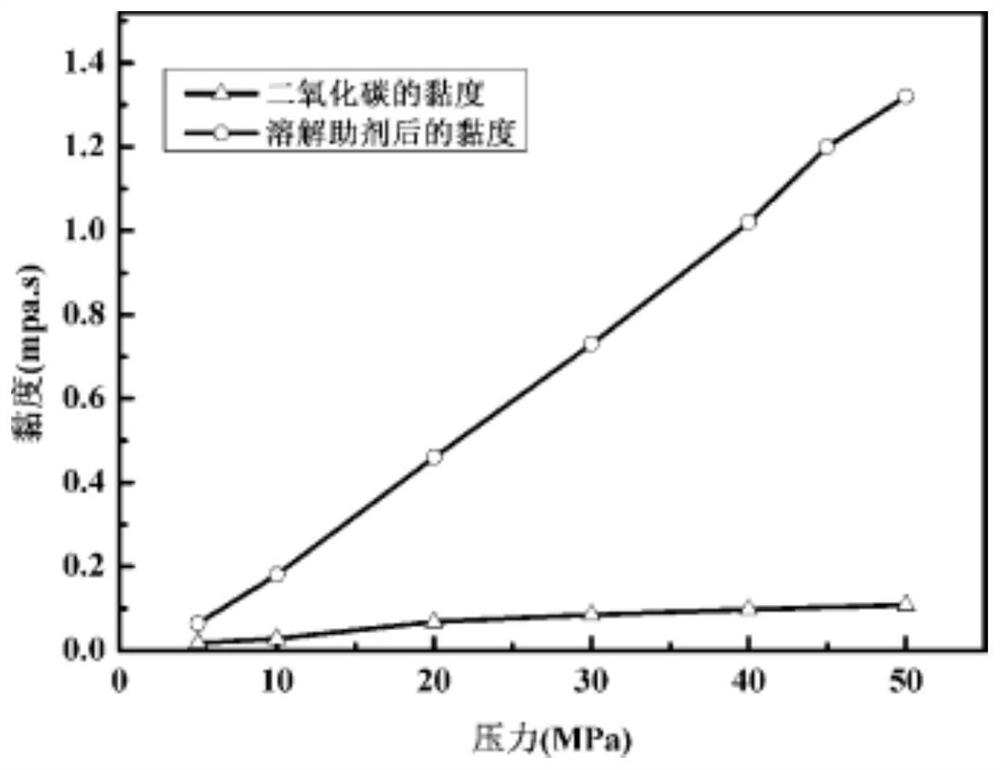

[0053] Experimental results: After being uniformly dissolved in supercritical carbon dioxide at 45°C, the measured cloud point pressure is 13MPa, and the solution viscosity is 1.3mPa·s, as figure 2 shown.

Embodiment 3

[0055] This embodiment provides a thickener, which is obtained by polymerizing the following polymerizable monomers under the action of an initiator:

[0056] Polymerized monomers: dodecafluoroheptyl methacrylate, 2-(dimethylamino) ethyl methacrylate and styrene, the molar percentages in the polymerized monomers are 58%, 15% and 27% respectively. The initiator is azobisisoheptanonitrile, and the dosage is 2.37×10 of the total monomer molar content -5 .

[0057] The polymerization reaction temperature was 55° C., and the reaction time was 24 hours.

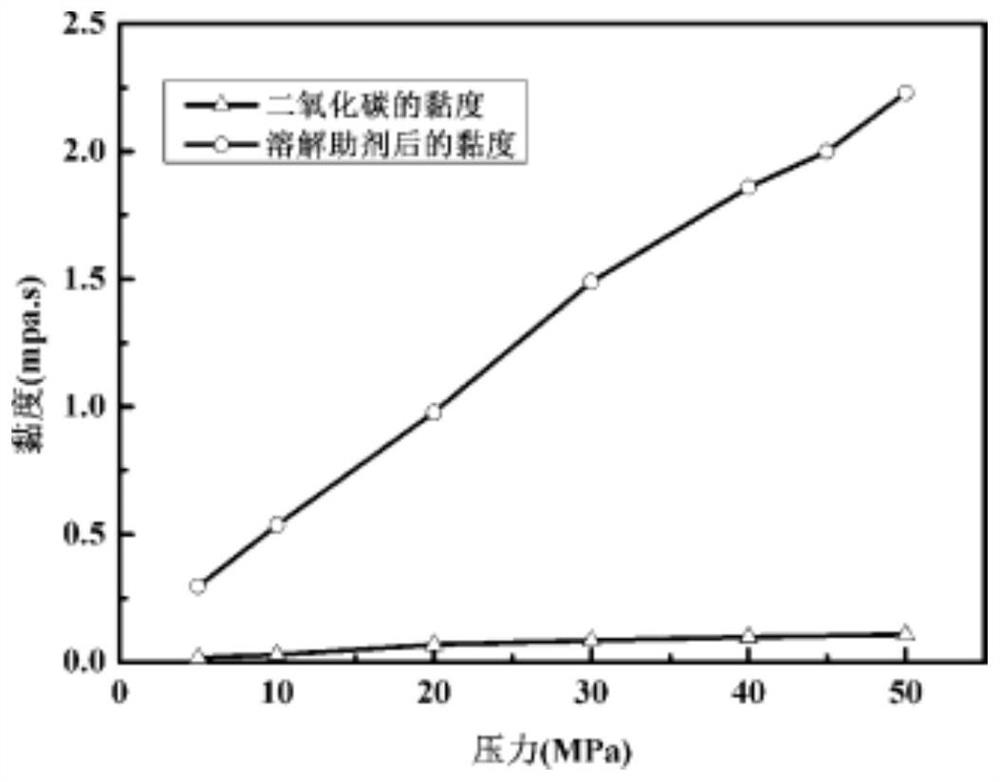

[0058] Experimental results: After being uniformly dissolved in supercritical carbon dioxide at 45°C, the measured cloud point pressure is 12MPa, and the solution viscosity is about 2.0mPa·s, as image 3 shown.

[0059] After the sample of Example 3 was dried, it was compressed into a tablet with KBr, and then measured using a Nicolet Nexus 470 FT-IR infrared spectrometer (Nicolet, USA). Figure 4 Be the infrared spectrogram of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com