A method for preparing multiple pickering emulsions from crystalline block copolymer micelles

A technology of block copolymers and copolymers, which is applied in the direction of emulsion transportation, pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve the problems of hazards, solid particles are not easy to be degraded, etc., achieve good barrier properties, overcome oil Effect of excess soluble emulsifier, good emulsion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] (1) Block copolymer PEG 2k -PCL 19.4k and PCL 1.9k -PEG 20k -PCL 1.9k Preparation of:

[0061] PEG 2k -PCL 19.4k Preparation of block copolymer: 0.5g polyethylene glycol monomethyl ether (average molecular weight is 2000Da), 5g ε-caprolactone monomer, 0.028g stannous octoate are placed in a dry flask, under argon protection , react at 120 °C for 12 hours; after the reaction, drop the reaction mixture into ice-n-hexane for precipitation, filter and dry to obtain PEG 2k -PCL 19.4k block copolymer.

[0062] PCL 1.9k -PEG 20k -PCL 1.9k Preparation of block copolymer: 2.5g polyethylene glycol (average molecular weight is 20000Da), 0.5g ε-caprolactone monomer, 0.015g stannous octoate are placed in a dry flask, under argon protection, in The reaction was carried out at 120°C for 12 hours; after the reaction, the reaction mixture was dropped into ice-n-hexane for precipitation, filtered and dried to obtain PCL 1.9k -PEG 20k -PCL 1.9k block copolymer.

[0063] Th...

Embodiment 2

[0069] (1) Block copolymer PCL 5.1k -PEG 8k -PCL 5.1k , PDLA5.8k -PEG 5k -PDLA 5.8k and PLLA 3k -PEG 10k -PLLA 3k Preparation of:

[0070] PCL 5.1k -PEG 8k -PCL 5.1k Preparation of block copolymer: 4g polyethylene glycol (average molecular weight is 8000Da), 5g ε-caprolactone monomer, 0.045g stannous octoate were placed in a dry flask, under argon protection, at 120 ° C The reaction was carried out for 12 hours; after the reaction, the reaction mixture was dropped into ice-n-hexane for precipitation, filtered and dried to obtain PCL 5.1k -PEG 8k -PCL 5.1k block copolymer.

[0071] PDLA 5.8k -PEG 5k -PDLA 5.8k Preparation of block copolymer: 2.08g polyethylene glycol (average molecular weight is 5000Da), 5g d-lactide monomer, 0.035g stannous octoate were placed in a dry flask, under argon protection, at 120 The reaction was carried out at °C for 12 hours; after the reaction was completed, the reaction mixture was dropped into ice-n-hexane to precipitate, filter...

Embodiment 3

[0079] (1) Block copolymer PEG 2k -PGA 5.2k , PEG 5k -PDLA 8k and PLLA 3.7k -PEG 5k -PLLA 3.7k Preparation of:

[0080] PEG 2k -PGA 5.2k Preparation of block copolymer: 2g polyethylene glycol monomethyl ether (average molecular weight is 2000Da), 5g glycolide monomer, 0.035g stannous octoate are placed in a dry flask, under argon protection, at 120 The reaction was carried out at ℃ for 12 hours; after the reaction, the reaction mixture was dropped into ice-n-hexane for precipitation, filtered and dried to obtain PEG 2k -PGA 5.2k block copolymer.

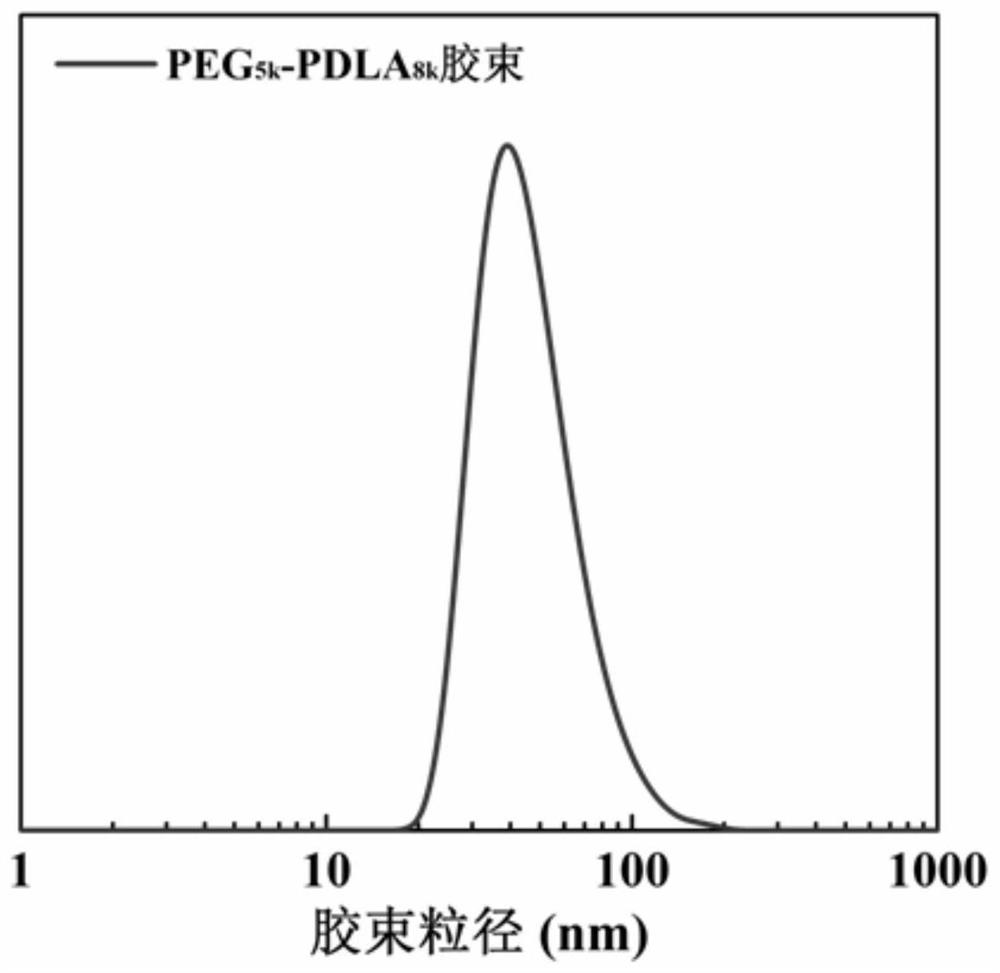

[0081] PEG 5k -PDLA 8k Preparation of block copolymer: 3.13g polyethylene glycol monomethyl ether (average molecular weight is 5000Da), 5g D-lactide monomer, 0.041g stannous octoate are placed in a dry flask, under argon protection , react at 120 °C for 12 hours; after the reaction, drop the reaction mixture into ice-n-hexane for precipitation, filter and dry to obtain PEG 5k -PDLA 8k block copolymer.

[0082] PLLA 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com