Fiber bragg grating hydrogen sensing system based on amorphous palladium-based alloy and sensor

A sensing system and fiber grating technology, applied in the field of hydrogen sensors, can solve the problems of fiber grating strain and temperature cross-sensitivity, large loss of coreless fiber, decreased accuracy, etc., to improve hydrogen embrittlement phenomenon, strong hydrogen permeability, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

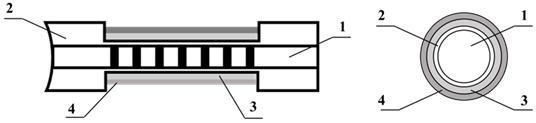

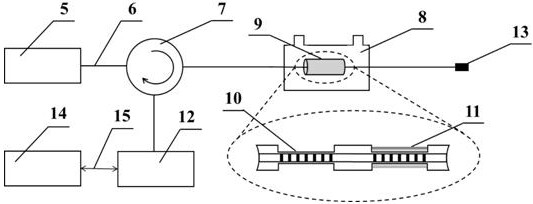

[0034]See attachedfigure 1 , Use hydrofluoric acid to etch the fiber cladding (2) engraved with fiber Bragg grating (1) to reduce its thickness, thereby improving the sensitivity of the sensor. The corroded cladding is used as the substrate, and a certain thickness of polyimide film and Ni film are successively coated as the adhesion layer (3). The purpose is to increase the adhesion between the sensor layer and the optical fiber cladding and prevent hydrogen Sensitive material falls off. The amorphous palladium-based alloy film coated on the outside of the adhesion layer constitutes the outermost sensing layer (4) of the hydrogen sensitive probe. The Pd-Cu-Si amorphous alloy film is selected as the hydrogen sensitive material. The preparation method is as follows: The method uses vacuum magnetron sputtering method, the target materials are 99.99% purity Pd target and 99.9% CuSi alloy target, the atomic ratio of CuSi alloy target is Cu:Si=5:17; the Pd target is connected to the DC p...

Embodiment 2

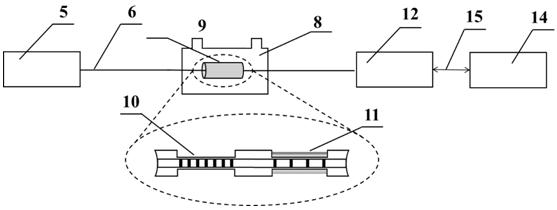

[0037]In addition to etching or using ultra-fine Bragg gratings to improve the sensitivity of fiber gratings, the strategy of using long-period gratings instead of Bragg gratings has also received widespread attention. Because the long-period grating wavelength changes not only due to strain, but also due to changes in the refractive index of the cladding and coating. And if the coating thickness is small enough, the effect of strain on the wavelength shift can be ignored. Therefore, in this example, the second grating type is chosen to be long-period grating. Moreover, because LPG itself has a higher sensitivity than FBG, the thickness of the Pd-Cu-Si thin layer in this embodiment is selected as 15 nm to obtain a shorter response and recovery time. Except for the above two parameters, the preparation method of the sensing system (9) is the same as that of Example 1.

[0038]However, because LPG is the coupling between the core fundamental mode and the cladding mode transmitted in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com