Corrosion-resistant thermosetting powder coating

A thermosetting powder, corrosion-resistant technology, applied in powder coatings, anti-corrosion coatings, polyester coatings, etc., can solve problems such as poor corrosion resistance, poor wettability and adhesion, and achieve excellent UV resistance and aging resistance performance, improvement of poor wettability, and improvement of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

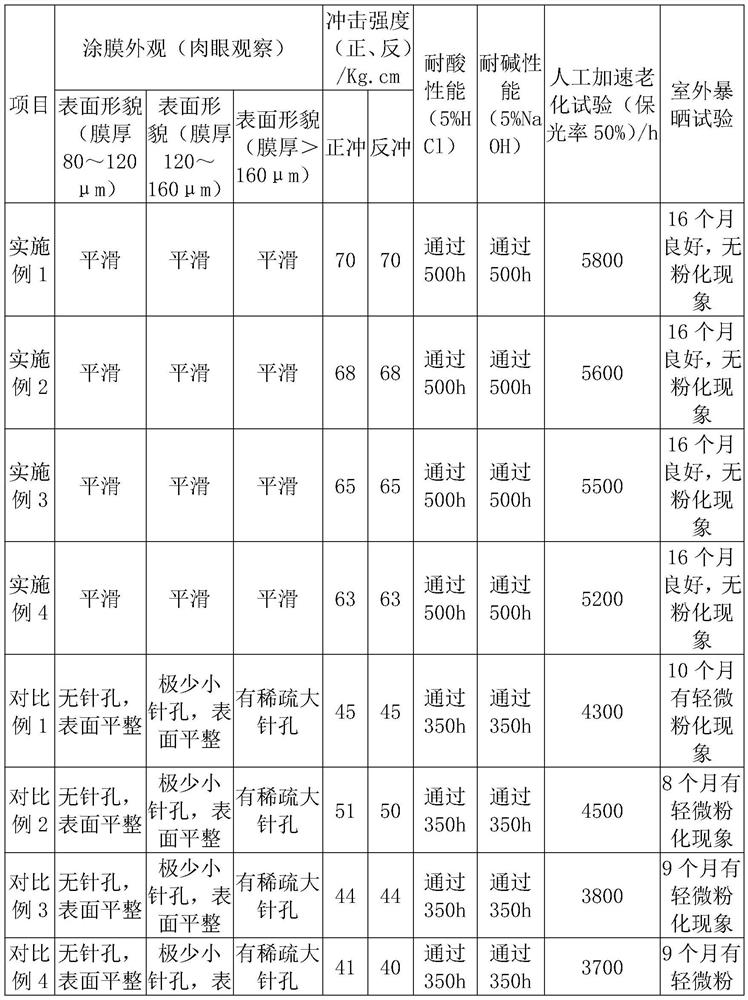

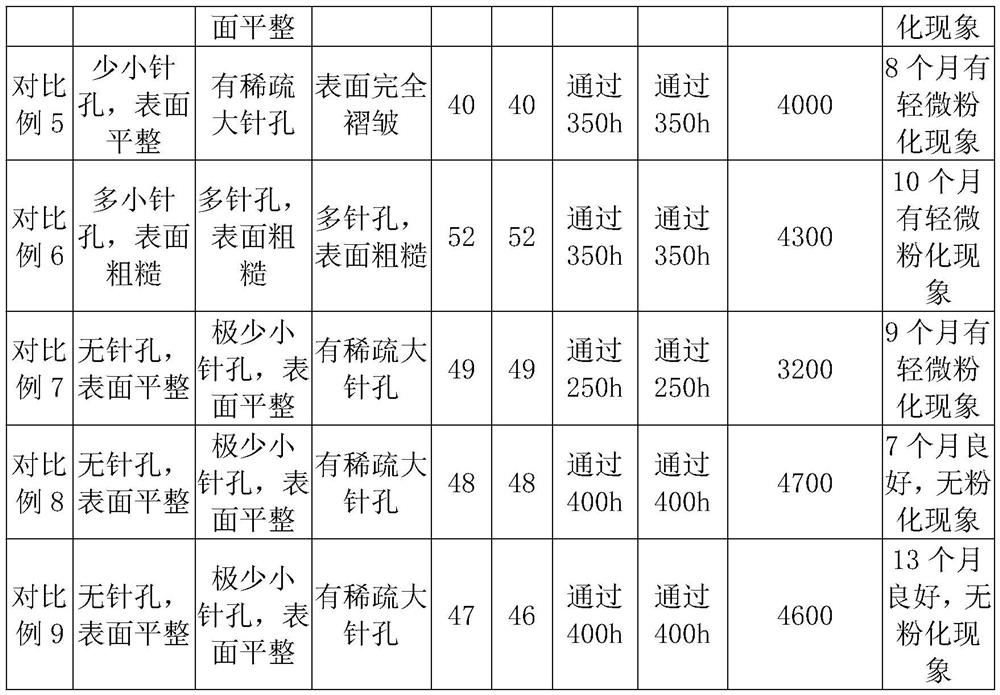

Examples

Embodiment 1

[0024] A corrosion-resistant thermosetting powder coating, which comprises the following components by weight: 45 parts of polyester resin, 6 parts of fluorocarbon resin, 7 parts of nano titanium dioxide, 9 parts of nano silicon dioxide, and 7 parts of curing agent , 0.45 parts of dispersant, 0.3 parts of defoamer, 0.2 parts of degassing agent, 0.5 parts of leveling agent, 0.8 parts of pigment and 7 parts of corrosion resistance agent.

[0025] Preferably, the curing agent is methyl ethyl ketone peroxide.

[0026] Preferably, the pigment is an ordinary inorganic pigment, an inorganic ceramic pigment, an organic pigment or a lead pigment.

[0027] Preferably, the dispersant is a polyester hyperdispersant.

[0028] Preferably, the defoamer is a polyether modified silicone defoamer.

[0029] Preferably, the degassing agent is benzoin.

[0030] Preferably, the leveling agent is a silicone leveling agent.

[0031] Preferably, the anti-corrosion agent is aluminum zinc phosphomol...

Embodiment 2

[0036] The preparation method of the corrosion-resistant thermosetting powder coating in this embodiment is the same as in Example 1, and the corrosion-resistant thermosetting powder coating in this embodiment includes the following components by weight: 46 parts of polyester resin, 8 parts of fluorocarbon resin, nano 7.5 parts of titanium dioxide, 10 parts of nano-silica, 8 parts of curing agent, 0.5 parts of dispersant, 0.4 parts of defoamer, 0.3 parts of degassing agent, 0.53 parts of leveling agent, 1 part of pigment and 7.8 parts of corrosion resistance agent.

[0037] Preferably, the curing agent is methyl ethyl ketone peroxide.

[0038] Preferably, the pigment is an ordinary inorganic pigment, an inorganic ceramic pigment, an organic pigment or a lead pigment.

[0039] Preferably, the dispersant is a polyester hyperdispersant.

[0040] Preferably, the defoamer is a polyether modified silicone defoamer.

[0041] Preferably, the degassing agent is benzoin.

[0042] Pre...

Embodiment 3

[0045] The preparation method of the corrosion-resistant thermosetting powder coating in this embodiment is the same as in Example 1, and the corrosion-resistant thermosetting powder coating in this embodiment includes the following components by weight: 40 parts of polyester resin, 5 parts of fluorocarbon resin, nano 5 parts of titanium dioxide, 8 parts of nano-silica, 6 parts of curing agent, 0.4 parts of dispersing agent, 0.2 parts of defoaming agent, 0.2 parts of degassing agent, 0.4 parts of leveling agent, 0.5 parts of pigment and 6 parts of corrosion resistance agent.

[0046] Preferably, the curing agent is methyl ethyl ketone peroxide.

[0047] Preferably, the pigment is an ordinary inorganic pigment, an inorganic ceramic pigment, an organic pigment or a lead pigment.

[0048] Preferably, the dispersant is a polyester hyperdispersant.

[0049] Preferably, the defoamer is a polyether modified silicone defoamer.

[0050] Preferably, the degassing agent is benzoin.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com