Graphene reinforced aluminum-based composite material with high conductivity and preparation method thereof

A technology for strengthening aluminum-based and composite materials, which is applied in the field of aluminum alloy smelting and rolling in the metallurgical industry, which can solve the problems of decreased electrical conductivity of aluminum alloys, and achieve the effects of increased strength, excellent performance, and high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is described in detail below:

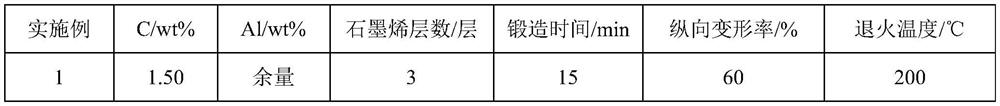

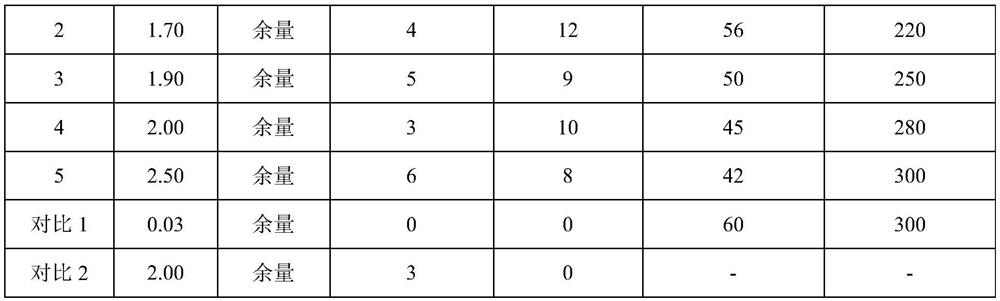

[0041] Table 1 is the value list of each embodiment 1-5 of the present invention and comparative example 1,2;

[0042] Table 2 is a list of the performance testing of each of Examples 1-5 and Comparative Examples 1 and 2 of the present invention.

[0043] Each embodiment of the present invention is prepared according to the following steps:

[0044] 1) Dry all raw materials in a drying oven for 2 hours to remove moisture. Raw materials include graphene, aluminum powder, and aluminum block;

[0045] 2) After the graphene is roughened, sensitized and activated, electroless aluminum plating is performed in an aluminum solution at room temperature.

[0046] 3) Heat the aluminum block at 750-800°C until it melts, and pass in argon for protection;

[0047] 4) Heating the forming abrasive to 300°C;

[0048] 5) Pour a spoonful of molten aluminum into the mold to form a solidified layer of molten aluminum, and then spread a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com