A kind of high-strength and high-conductivity wear-resistant aluminum matrix composite material and its preparation method

An aluminum-based composite material and high-conductivity technology, which is applied in the field of aluminum alloy smelting in the metallurgical industry, can solve the problems of aluminum alloy strength, wear resistance and electrical conductivity constraints, and achieve the effects of excellent quality, simplified production process and improved strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in detail below:

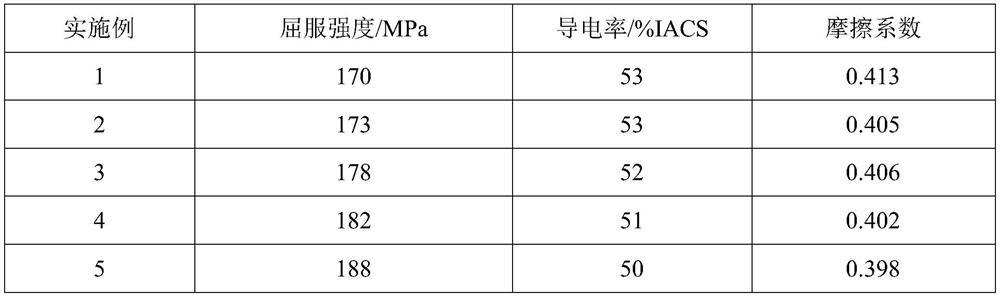

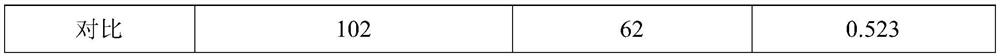

[0040] Table 1 is the value list of each embodiment of the present invention and comparative examples;

[0041] Table 2 is a list of performance testing situations of each embodiment of the present invention and comparative examples.

[0042] Each embodiment of the present invention is prepared according to the following steps:

[0043] 1) Dry all the raw materials in a drying oven for 3 hours to remove moisture. The raw materials include graphene, aluminum flux, aluminum block, silicon block, silver block, magnesium block, refining agent and slag remover.

[0044] 2) Fully mix graphene and aluminum brazing flux in a mixer, the mixing time is more than 30min, and the mixing ratio of graphene and aluminum brazing flux is ≤1:5;

[0045] 3) Melting the aluminum block and the silicon block at 700-800°C to obtain the molten material;

[0046] 4) Add silver nuggets and magnesium nuggets, and stir for 10-15 minutes;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com