High-insulation high-flame-retardant double-component epoxy coating and preparation method thereof

An epoxy coating, high flame-retardant technology, applied in epoxy resin coatings, coatings, fireproof coatings, etc., can solve the problems of high brittleness, flammability, single performance, etc., achieve good adhesion and reduce curing shrinkage , Improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

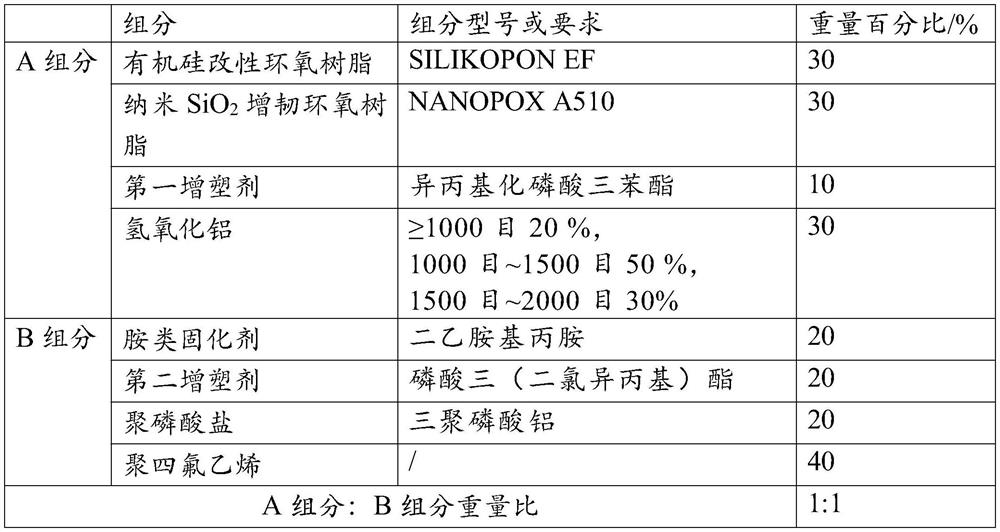

[0038] This example provides a high-insulation and high-flame-retardant two-component epoxy coating, which is formed by mixing component A and component B, wherein the types and proportions of component A and component B are shown in Table 1 .

[0039] Table 1 Example 1 components and proportioning ratio

[0040]

[0041] The preparation method of the high insulation and high flame retardant two-component epoxy coating of the present embodiment comprises the following steps:

[0042] S1, weigh each component according to the composition of component A in Table 1, and add the first plasticizer to the silicone modified epoxy resin and nano-SiO 2In the mixture of toughening epoxy resin, after stirring evenly, aluminum hydroxide was added while stirring, the stirring speed was 300r / min, and after the aluminum hydroxide was added, it was stirred for another 30 minutes to obtain component A.

[0043] S2, weigh each component according to the composition of component B in Table ...

Embodiment 2

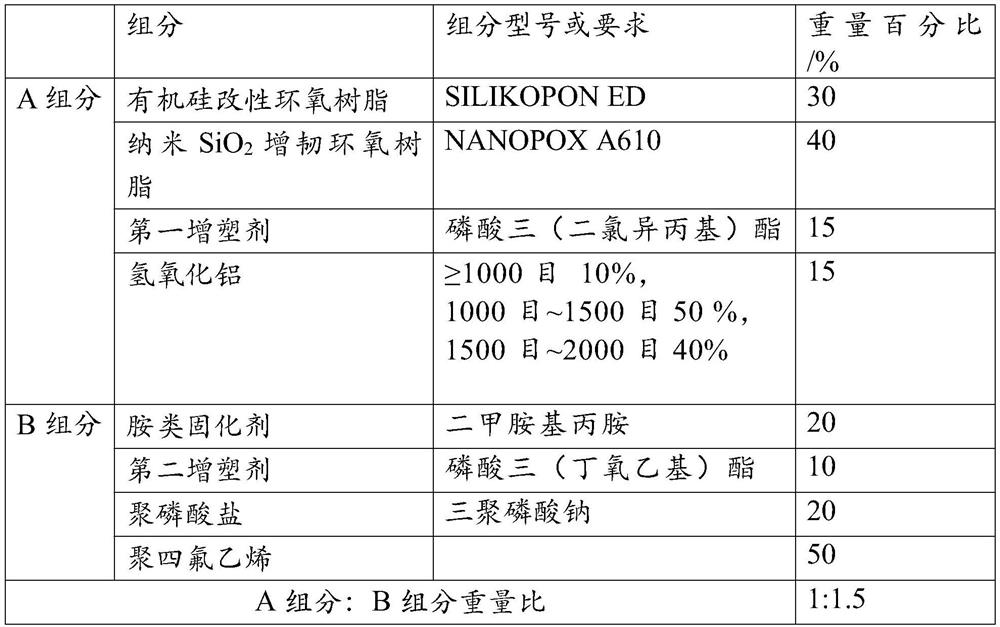

[0046] This example provides a high-insulation and high-flame-retardant two-component epoxy coating, which is formed by mixing component A and component B, wherein the types and proportions of component A and component B are shown in Table 2 .

[0047] The preparation method of this embodiment is the same as that of Example 1, but the components and proportioning ratio are in Table 2.

[0048] Table 2 Example 2 components and proportioning ratio

[0049]

Embodiment 3

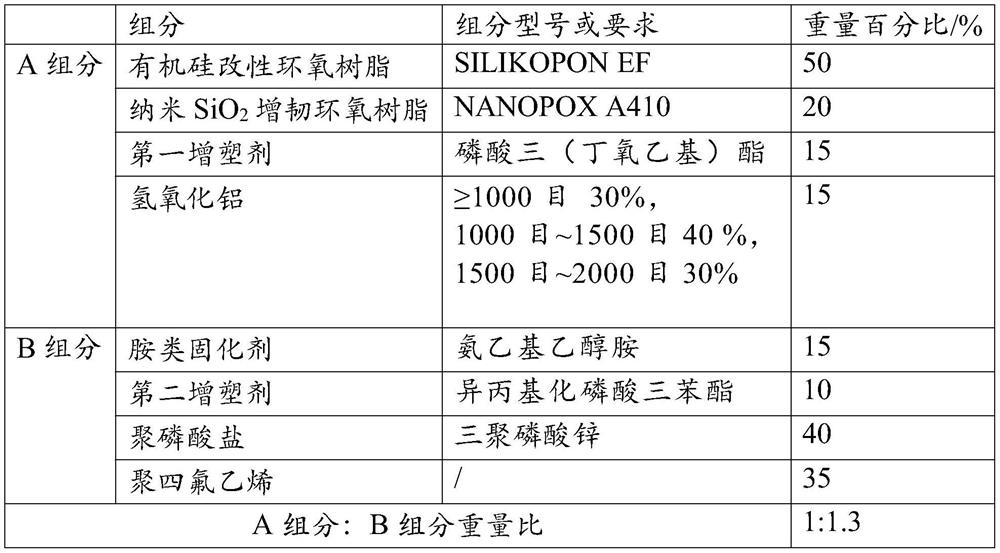

[0051] This example provides a high-insulation and high-flame-retardant two-component epoxy coating, which is formed by mixing component A and component B, wherein the components and proportions of component A and component B are shown in the table 3.

[0052] The preparation method of this embodiment is the same as that of Example 1, but the components and proportioning ratio are in Table 3.

[0053] Table 3 Example 3 components and proportioning ratio

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com