Environment-friendly polypropylene melt-blown material and preparation method thereof

A polypropylene melt-blown, environmentally friendly technology, applied in the field of non-woven materials, can solve problems such as high VOC content, strong odor, and poor processing stability, and achieve the effects of low VOC content, simple production process, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

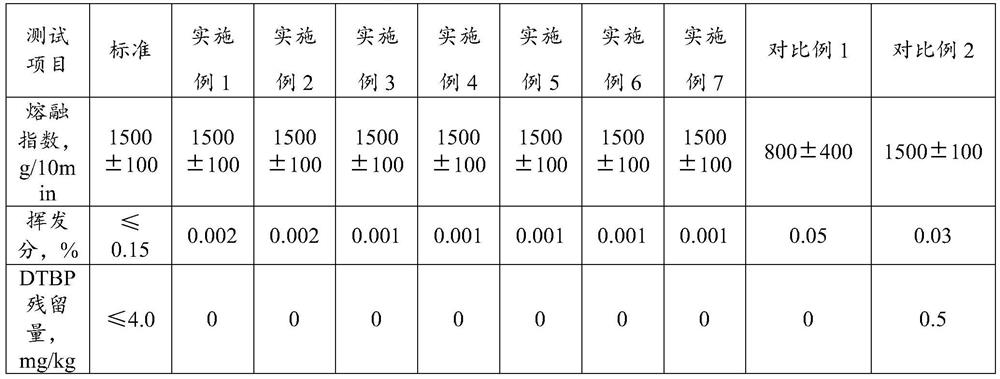

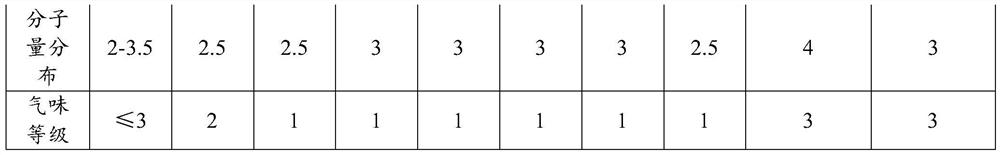

Examples

preparation example Construction

[0057] In the second aspect, the preparation method of the environment-friendly polypropylene melt-blown material in the first aspect is provided, which includes the following steps: weighing each raw material according to the proportion, mixing the raw materials uniformly to obtain a mixture; then extruding the mixture with a twin-screw The extruder is extruded at a temperature of 180-220°C, drawn into strips, air-cooled and pelletized, and the environmentally friendly polypropylene melt-blown material can be obtained after drying.

[0058] Compared with the traditional method, the environmentally friendly polypropylene melt blown material of the present invention has the characteristics of wide source of raw materials, simple production process, high production efficiency, safe and reliable production process, stable product quality, high product quality, no pollution to the environment, and easy to realize large-scale production. Continuous production.

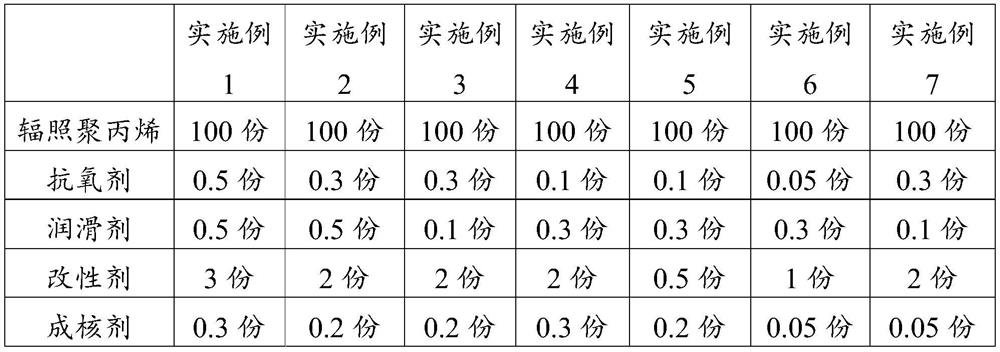

Embodiment 1

[0064] An environment-friendly polypropylene melt-blown material, which is made of the following raw materials in parts by weight: 100 parts of irradiated polypropylene; 0.5 parts of antioxidant; 0.5 parts of lubricant; 3 parts of modifier; 0.3 parts of nucleating agent.

[0065] Wherein, the preparation method of the irradiated polypropylene is:

[0066] The first irradiation treatment: the polypropylene is subjected to the first irradiation treatment through an electron accelerator or a cobalt source to obtain pre-irradiated polypropylene, wherein the irradiation dose is 5Mrad and the irradiation time is 30s;

[0067] Extrusion granulation treatment: after mixing the pre-irradiated polypropylene, antioxidant and lubricant, extruding through an extruder at a temperature of 180-220°C, drawing strands, air-cooling, pelletizing, and drying to obtain Semi-finished polypropylene; Wherein, the weight ratio of described pre-irradiated polypropylene, antioxidant and lubricant is 100:...

Embodiment 2

[0072] An environment-friendly polypropylene melt-blown material, which is made of the following raw materials in parts by weight: 100 parts of irradiated polypropylene; 0.3 parts of antioxidant; 0.5 parts of lubricant; 2 parts of modifier; 0.2 parts of nucleating agent.

[0073] Wherein, the preparation method of the irradiated polypropylene is:

[0074] The first irradiation treatment: the polypropylene is subjected to the first irradiation treatment through an electron accelerator or a cobalt source to obtain pre-irradiated polypropylene, wherein the irradiation dose is 5 Mrad, and the irradiation time is 20s;

[0075] Extrusion granulation treatment: after mixing the pre-irradiated polypropylene, antioxidant and lubricant, extruding through an extruder at a temperature of 180-220°C, drawing strands, air-cooling, pelletizing, and drying to obtain Semi-finished polypropylene; Wherein, the weight ratio of described pre-irradiated polypropylene, antioxidant and lubricant is 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com