Device and method for synchronous electrolysis/membrane separating/advanced oxidation cooperative treatment of ammonium sulfate-containing wastewater and organic wastewater

An organic waste water and advanced oxidation technology, applied in the field of water treatment, can solve the problems of anode material consumption, no ammonium sulfate floating particles, large reaction current, etc., achieve high membrane flux, inhibit the generation and utilization of membrane fouling phenomenon high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

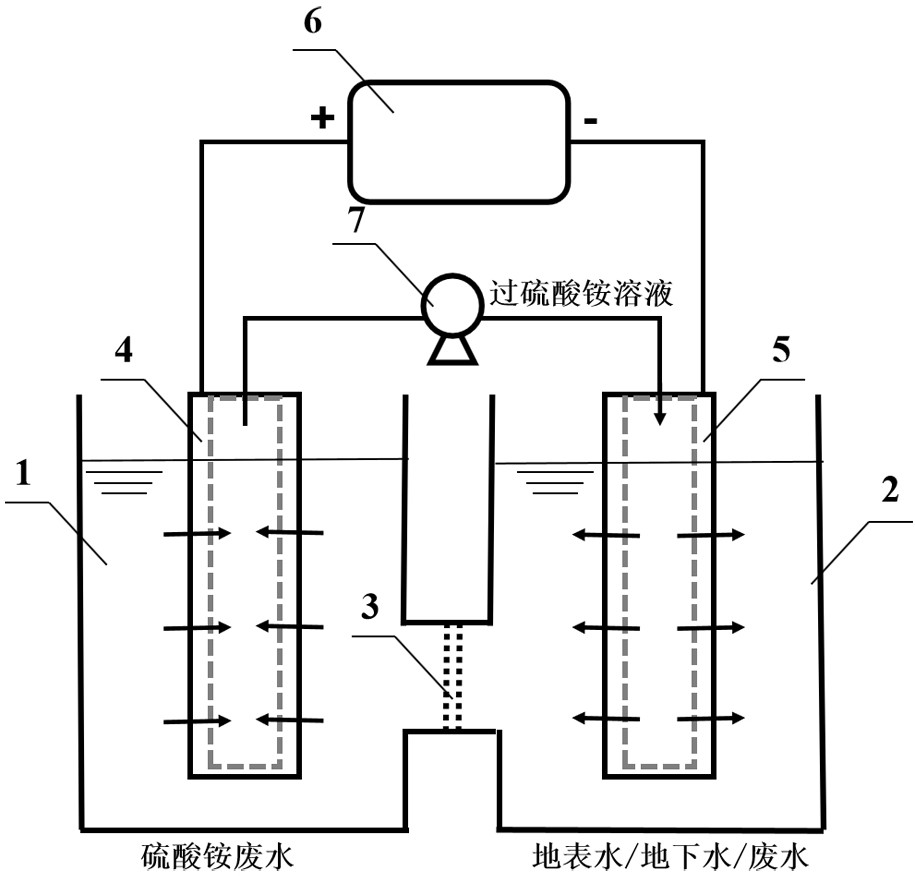

[0056] A method for synchronous electrolysis / membrane separation / advanced oxidation co-treatment of ammonium sulfate-containing wastewater and organic wastewater, the device such as figure 1 As shown, its construction includes the following steps:

[0057] (1) A porous tubular platinum electrode was selected as the anode membrane electrode (the average pore size was 0.42 μm, and the electrode area was 31.4 cm 2 ), the porous tubular titanium electrode is the cathode membrane electrode (the average pore size is 0.61 μm, and the electrode area is 31.4 cm 2 ) and power supply system (the current density is 800 A / m 3 , with an electrode spacing of 10 cm). The anode membrane electrode is arranged in the ammonium sulfate wastewater treatment chamber, and the cathode membrane electrode is arranged in the organic wastewater treatment chamber. The electrosynthesis p-aminophenol waste liquid containing ammonium sulfate (the concentration of ammonium sulfate is 0.55 mol / L, the main or...

Embodiment 2

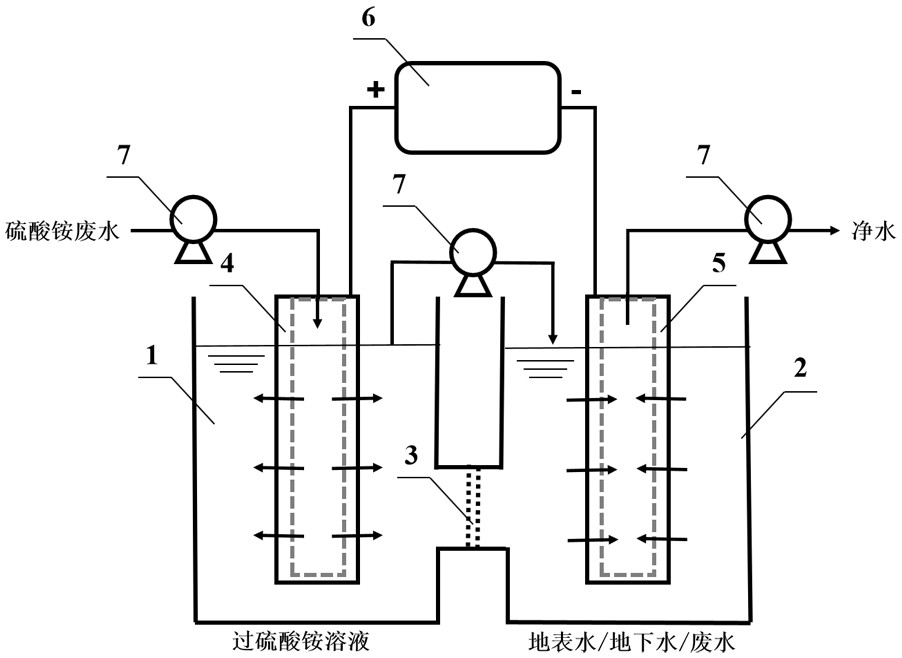

[0060] A method for synchronous electrolysis / membrane separation / advanced oxidation co-treatment of ammonium sulfate-containing wastewater and organic wastewater, the device such as figure 2 As shown, its construction includes the following steps:

[0061] (1) The porous tubular titanium dioxide electrode is selected as the anode membrane electrode (the average pore diameter is 0.52 μm, and the electrode area is 75.36cm 2 ), the porous tubular graphite electrode is the cathode membrane electrode (the average pore size is 0.57 μm, and the electrode area is 75.36 cm 2 ) and power supply system (current density is 600 A / m 3 , the electrode spacing is 15 cm). The anode membrane electrode is arranged in the ammonium sulfate wastewater treatment chamber, and the cathode membrane electrode is arranged in the organic wastewater treatment chamber. The desulfurization and denitrification absorption liquid containing ammonium sulfate (ammonium sulfate concentration 0.86 mol / L) is pas...

Embodiment 3

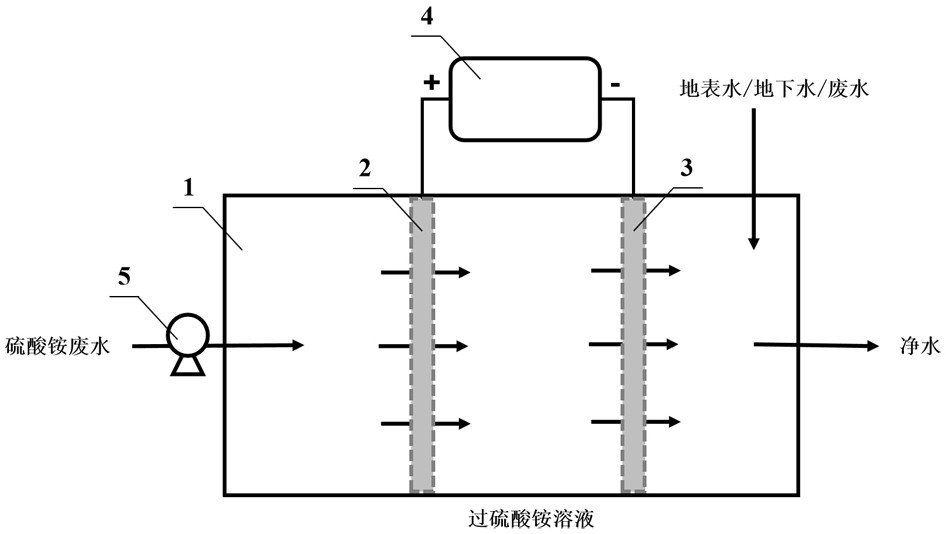

[0064] A method for synchronous electrolysis / membrane separation / advanced oxidation co-treatment of ammonium sulfate-containing wastewater and organic wastewater, the device such as image 3 As shown, its construction includes the following steps:

[0065] (1) A porous plate-shaped boron-doped diamond electrode was selected as the anode membrane electrode (the average pore size was 0.68 μm, and the electrode area was 400 cm 2 ), the porous plate-shaped carbon-based electrode is the cathode membrane electrode (the average pore size is 0.61 μm, and the electrode area is 400 cm 2 ) and power supply system (the current density is 1200 A / m 3 , the electrode spacing is 20 cm). The anode membrane electrode is arranged in the ammonium sulfate wastewater treatment chamber, and the cathode membrane electrode is arranged in the organic wastewater treatment chamber. Inject ammonium sulfate-containing acrylonitrile production wastewater (ammonium sulfate concentration 0.22 mol / L, main o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Electrode area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com