Production method of electronic grade sulfuric acid

A production method and electronic-grade technology are applied in the production of sulfuric acid and the production of electronic-grade sulfuric acid, which can solve the problems of difficult gas removal, low safety, and high operating temperature, so as to ensure evaporation efficiency and output, and improve utilization rate. , good degassing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

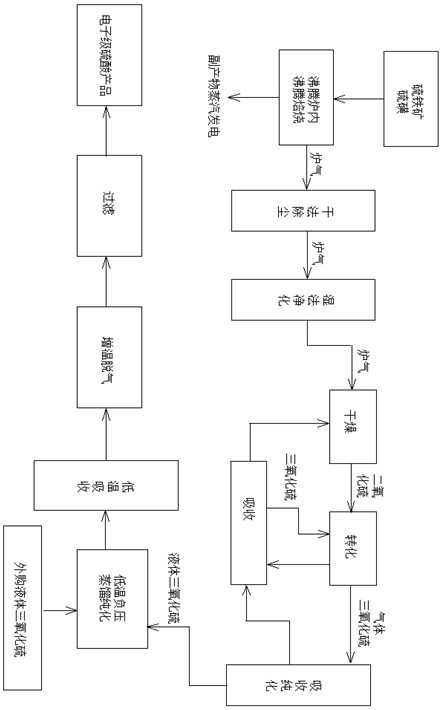

[0037] In order to be able to understand the technical means of the present invention more clearly and implement it according to the contents of the description, the specific implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

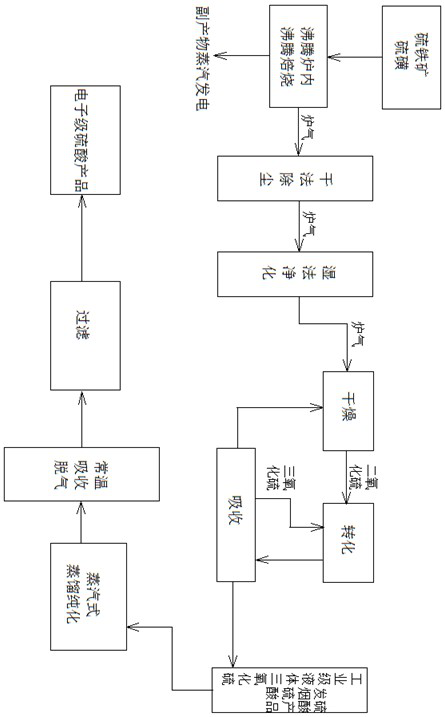

[0038] The front-end preparation process of this specific embodiment is consistent with the prior art, as follows:

[0039] Sulfur-containing substances such as pyrite and sulfur are boiled and roasted in a fluidized fluidized furnace, and the furnace gas produced mainly contains sulfur dioxide, oxygen, nitrogen, water vapor, compounds such as arsenic and selenium, and mineral dust; the above-mentioned furnace gas is sequentially passed through After dry dust removal, wet purification and drying treatment, a furnace gas mainly containing sulfur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com