A method of using supramolecular inclusion agent to close the antibacterial agent activity in collagen solution

A supramolecular, antibacterial technology, applied in the field of antibacterial activity, can solve problems such as nerve damage, damage to the inherent biocompatibility of collagen, and toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

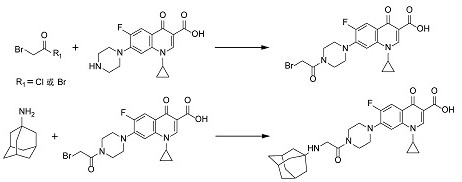

[0022] (1) Disperse 2 parts of ciprofloxacin in 40 parts of dichloromethane, then add 50 parts of distilled water dissolved in 3 parts of potassium carbonate into it, and stir evenly to obtain component 1; at the same time, 8 parts of bromoacetyl bromide Dissolved in 20 parts of dichloromethane, slowly added to component 1 at 0°C within 1.5 hours, continued to stir for 2 hours, then raised to room temperature and stirred for 13 hours; finally, the product was washed with 5% hydrochloric acid aqueous solution and distilled water successively After washing, the organic layer was taken, and vacuum-dried to constant weight to obtain the first-step synthetic product;

[0023] (2) Dissolve 2 parts of the product synthesized in the first step in 30 parts of dichloromethane, then add 3 parts of amantadine to the above solution, and continue stirring at 50°C for 13 hours. The obtained product is vacuum-dried to constant weight to obtain the target product product;

[0024] (3) Add 0.2...

Embodiment 2

[0028] (1) Disperse 1 part of ciprofloxacin in 30 parts of toluene, then add 40 parts of distilled water dissolved in 2 parts of sodium carbonate into it, stir well to obtain component 1; at the same time, dissolve 5 parts of bromoacetyl bromide in 10 parts of toluene, at 2°C, slowly added to component 1 within 1 hour, continued to stir for 1 hour, then raised to room temperature and stirred for 12 hours; finally, the product was washed successively with 5% sulfuric acid aqueous solution and distilled water, and the organic layer, and vacuum-dried to constant weight to obtain the first-step synthesis product;

[0029] (2) Dissolve 1 part of the product synthesized in the first step in 10 parts of toluene, then add 2 parts of amantadine to the above solution, continue stirring at 40°C for 12 hours, and vacuum-dry the obtained product to constant weight to obtain the target product;

[0030] (3) Add 0.1 part of the above-mentioned target product to 100 parts of collagen solution...

Embodiment 3

[0034] (1) Disperse 4 parts of ciprofloxacin in 60 parts of n-butanol, then add 70 parts of distilled water dissolved in 6 parts of calcium bicarbonate into it, and stir evenly to obtain component 1; at the same time, 13 parts of bromoacetyl chloride Parts were dissolved in 40 parts of n-butanol, at 4 ° C, slowly added to component 1 within 2 hours, continued to stir for 4 hours, and then raised to room temperature and stirred for 14 hours; finally, the product was washed with 10% aqueous nitric acid and distilled water Washing in sequence, taking the organic layer, and vacuum drying to constant weight to obtain the first-step synthesis product;

[0035] (2) Dissolve 3 parts of the product synthesized in the first step in 40 parts of n-butanol, then add 4 parts of amantadine to the above solution, and continue stirring at 60°C for 14 hours. The obtained product is vacuum-dried to constant weight to obtain the target product;

[0036] (3) Add 0.4 parts of the above target prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com